Offices

HEADQUARTER

Germany

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REGIONAL OFFICE

Great Britain

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REGIONAL OFFICE

United Arab Emirates

- Intensive Filter Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Glass Industry Air and Dust Filtration Solutions

The glass manufacturing industry is characterized by high temperatures, the use of raw materials that generate fine dust, and the production of volatile fumes. These factors pose significant risks to worker health, environmental compliance, and product quality. Our air and dust filtration systems are engineered specifically for the glass industry, ensuring efficient capture of airborne particulate matter, fumes, and gases at critical stages of production. Our solutions help manufacturers meet regulatory standards, protect workers, and ensure that products maintain their high quality without contamination.

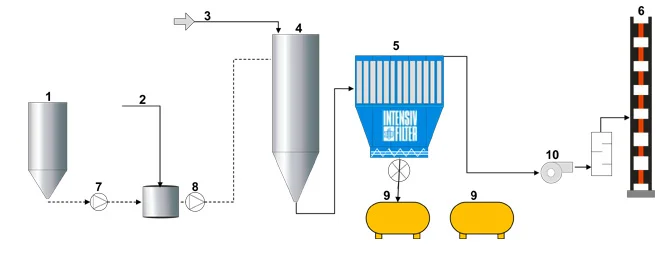

Dust Filtration Process in the Glass Industry

Filter for glass-kiln

- 1. NaOH tank

- 2. Water

- 3. Hot gas from the glass trough

- 4. Quench reactor

- 5. Filter for glass-kiln

- 6. Chimney

- 7. Dosing pump

- 8. Quench pump

- 9. Transport container

- 10. Induced draft

Required specifications

Typical design data | Residue combustion furnaces |

|---|---|

Gas volume | 38,000 |

Gas temperature | 180 – 200 |

Type of dust | Sodium sulphate, soda, borax, quartz |

Raw gas dust content | 10 – 25 |

Residual dust content | < 10 |

Cleaning | offline |

Filter medium | Polyimide |

Sorbent | Sodium hydroxide |

Applications for Glass Industry Dust Control

Filters airborne dust during the handling and storage of raw materials like silica, soda ash, and limestone, ensuring that dust doesn’t spread to other areas of the facility.

Controls airborne pollutants and particulate matter produced during the melting process, ensuring clean air around high-temperature furnace areas.

Reduces dust and fine particulate matter generated during the forming and molding of glass products, preventing contamination and enhancing product integrity.

Regulatory Landscape for Dust Control |

|---|

Air Quality Standards Compliance |

Worker Health & Safety Compliance |

Fire & Explosion Hazard Prevention |

Environmental Protection Compliance |

Real-Time Emission Monitoring |

Heat and Corrosion Resistance |

Reduced Downtime and Maintenance Costs |

Quality and Product Consistency |

Operational Cost Savings |

Dust Control Challenges in the Glass Industry |

|---|

High Dust Generation |

Heat and Corrosive Environments |

Worker Safety Risks |

Combustion and Explosion Hazards |

Maintaining Product Quality and Purity |

Product Contamination |

Equipment Wear and Tear |

Fumes and Gaseous Emissions |

Cross-Contamination |

Key Considerations for Effective Dust Control |

|---|

Efficient Dust and Fume Capture |

Chemical and Heat Resistance |

Optimized Airflow and Pressure Management |

Advanced Filtration Materials |

Routine Maintenance & Inspections |

Compliance with Regulatory Standards |

Customized Filtration Solutions |

Risk Mitigation for Hazardous Chemicals |

Flexible System Configurations |

Connect with us for Expert Consultation

Explore Our Other Services !

Frequently Asked Questions

Glass production generates significant amounts of fine, abrasive dust—especially silica-rich particles- during the handling of raw materials like sand, soda ash, limestone, and cullet. These particles pose serious health risks such as silicosis and respiratory issues. Effective filtration ensures worker safety, prevents equipment wear, maintains product purity, and enables compliance with environmental regulations requiring capture efficiencies up to 99.9%

Dust from glass crushing and handling is extremely abrasive and chemically inert, while silica content makes it carcinogenic at microscopic sizes. Cullet dust is highly irregular and abrasive, accelerating filter media wear and necessitating robust inlet design, heavy-duty hoppers, and air flow management to prevent rapid degradation of filter bags or cartridges .

Glass facilities typically employ fabric filters (baghouses) to achieve high-efficiency particulate control. In applications involving high temperatures or heavy silica abrasiveness, durable baghouse systems with abrasion-resistant media or cartridge-type collectors may be preferred. For processes generating acid gases or volatile emissions, supplementary wet scrubbers may be required.