Cement and Minerals

Offices

HEADQUARTER

Germany

-

Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REGIONAL OFFICE

Great Britain

-

Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REGIONAL OFFICE

United Arab Emirates

-

Intensive Filter Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Intensiv-Filter Himenviro: Cement Industry Environmental Solutions

Home » Industries » Cement and Minerals

Cement production is similar all over the world. Raw materials such as limestone, clay and sand and other aggregates are mined in quarries. They are ground and milled. The raw mix is fired in a rotary furnace at approx. 1,450 degrees Celsius to make clinker brick. In another mill, gypsum is added to form the end product – cement. The pollutants released in this branch of industry are considerable. With Intensiv-Filter Himenviro filtering installations, dust emissions can be lowered by more than 99%. Intensiv Filter Industries analyze your emission values and draw up a concept for the best economical solution for your requirements.

Application for Cement and Minerals

- Reverse Air Bag house for Kiln and Raw mill , Cement Mill

- Cement Mill Bag filter

- Clinker Cooler Dust Extraction System like ESP and Bag filter

- Coal Mill bag filter

- Packing Plant Dust Extraction System

- Blending Cyclones Dust Extraction System

- Raw Material Handling, Crushing & Screening Dust Extraction System

- Retrofit of electrostatic precipitator to bag filter

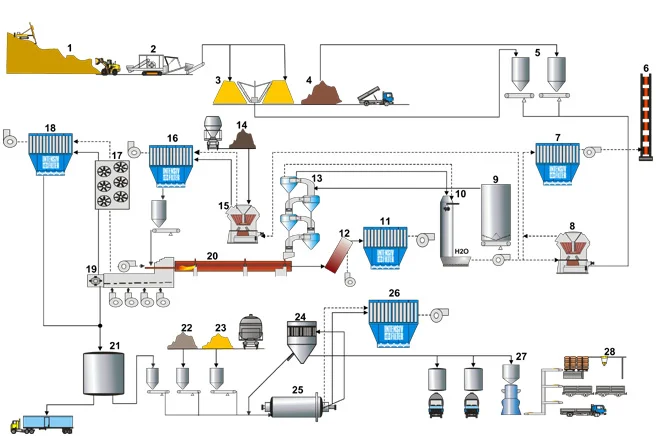

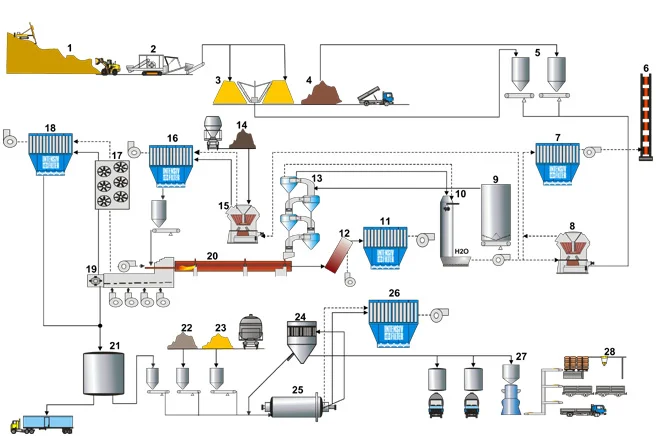

Process

Dry cement process

- 1. Quarry

- 2. Crusher plant

- 3. Raw material homogenization

- 4. Aggregates

- 5. Raw mill feeding silo

- 6. Main stack

- 7. Bag filter for kiln-/raw mill

- 8. Vertical raw mill

- 9. Raw material feeding silo

- 10. Gas conditioning tower

- 11. Bag filter for alkali bypass

- 12. Bypass mixing chamber

- 13. Cyclone pre-heater

- 14. Raw coal

- 15. Vertical coal grinding mill

- 16. Bag filter for coal grinding plant

- 17. Tubular cooler

- 18. Bag filter for clinker cooler

- 19. Clinker cooler

- 20. Rotary kiln

- 21. Clinker silo

- 22. Gypsum

- 23. Minerals

- 24. Separator

- 25. Cement finish mill

- 26. Bag filter for cement finish mill

- 27. Packaging plant

- 28. Palletization plant

Required specifications

Filter Title PJM

|

Typical design data

|

Unit of measure

|

Kiln-/raw mill

|

|---|---|---|

|

Gas volume

|

m³/h

|

< 1,200,000

|

|

Gas temperature

|

°C

|

85 – 110 compound / < 250 direct

|

|

Type of dust

|

|

CaCO3, CaO

|

|

Residual dust content

|

g/m³

|

< 550

|

|

Raw gas dust content

|

mg/m³

|

< 10

|

|

Cleaning

|

|

online / offline

|

|

Filter medium

|

|

PEA, NX, PPS, PI, GL/PTFE

|

Filter Title PJM

|

Typical design data

|

Unit of measure

|

Alkali bypass

|

|---|---|---|

|

Gas volume

|

m³/h

|

< 800,000

|

|

Gas temperature

|

°C

|

< 250

|

|

Type of dust

|

|

CaCO3, CaO, Alkali

|

|

Residual dust content

|

g/m³

|

< 25

|

|

Raw gas dust content

|

mg/m³

|

< 10

|

|

Cleaning

|

|

offline

|

|

Filter medium

|

|

PTFE-PI / GL-PTFE

|

Filter title IF JCC / IF JC

|

Typical design data

|

Unit of measure

|

Coal mill

|

|---|---|---|

|

Gas volume

|

m³/h

|

< 450,000

|

|

Gas temperature

|

°C

|

80 – 110

|

|

Type of dust

|

|

Coal

|

|

Residual dust content

|

g/m³

|

< 250

|

|

Raw gas dust content

|

mg/m³

|

< 10

|

|

Cleaning

|

|

online

|

|

Filter medium

|

|

PEA / PAN

|

Tubular cooler IF TC

|

Typical design data

|

Unit of measure

|

Tubular cooler

|

|---|---|---|

|

Gas volume

|

m³/h

|

< 1,600,000

|

|

Gas temperature in

|

°C

|

250 – 350

|

|

Gas temperature out

|

°C

|

120 – 200

|

Filter title PJM

|

Typical design data

|

Unit of measure

|

Clinker cooler

|

|---|---|---|

|

Gas volume

|

m³/h

|

< 800,000

|

|

Gas temperature

|

°C

|

120 – 180

|

|

Type of dust

|

|

Clinker

|

|

Raw gas dust content

|

g/m³

|

10 – 30

|

|

Residual dust content

|

mg/m³

|

< 10

|

|

Cleaning

|

|

online

|

|

Filter medium

|

|

PE / NX /PI

|

Filter title PJM

|

Typical design data

|

Unit of measure

|

Cement finish mill

|

|---|---|---|

|

Gas volume

|

m³/h

|

< 300,000

|

|

Gas temperature

|

°C

|

80 – 110

|

|

Type of dust

|

|

Cement, slag

|

|

Raw gas dust content

|

g/m³

|

< 350

|

|

Residual dust content

|

mg/m³

|

< 10

|

|

Cleaning

|

|

online / offline

|

|

Filter medium

|

|

PE / PEA

|

Our Services

In the food industry, spraying tower drying plants are used in the production of pulverized goods (milk powder, baby food, etc.).

Case Study

Read Related Case Studies