Chemicals

Offices

HEADQUARTER

Germany

-

Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REGIONAL OFFICE

Great Britain

-

Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REGIONAL OFFICE

United Arab Emirates

-

Intensive Filter Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Intensiv-Filter Himenviro: Chemical Industry Environmental Solutions

Home » Industries » Chemicals

Intensiv-Filter Himenviro has installed numerous filters in various applications of Chemical plants.

1. Calcium carbide furnace pulse Jet Unit for DSCL Kota having a capacity of 500,000m3/hr

2. De-dusting system Bag filter unit for Ball mill and transfer points for Asian Paints Noida

3. Detergent powder process Bag filter for Ethiopia and Peru

4. Calcium carbonate process bag filter for Toothpaste manufacturing in PERU

5. Improvement and optimization of gas flow distribution systems

6. Rapping optimization

Application

- Process Filters in Chemical Plants

- Dust and Fume Extraction Systems in Chemical

- Electrostatic Precipitators

Process

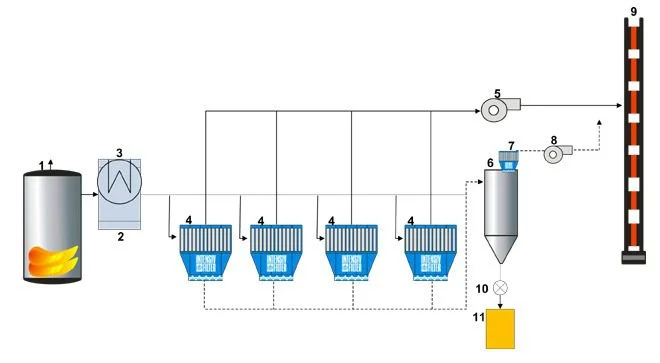

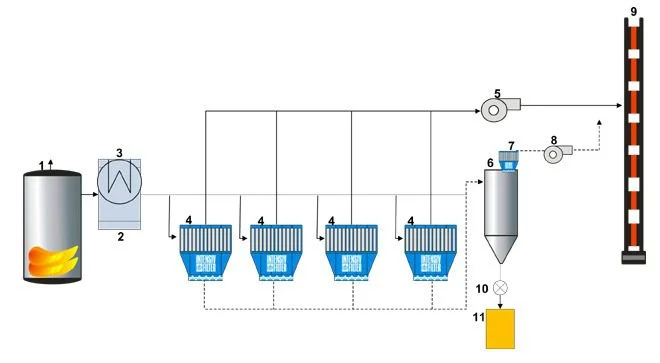

Climate change and climate protection are playing an increasingly important role. Therefore the various business units of the chemical industry have committed themselves to reducing emissions, for instance (“Responsible Care”). Based on the example of a residue combustion plant in a chemical company, dust featuring difficult cleaning properties is removed from the system. A filtering precipitator is used for waste gas dust removal.

- 1. Combustion plant

- 2. Steam boiler

- 3. Heat exchanger

- 4. Filter for residue combustion furnace

- 5. Induced draft fan

- 6. Silo

- 7. Silo filter

- 8. Conveyor ventilator

- 9. Chimney

- 10. Dust discharge

- 11. Disposal

Required specifications

|

Typical design data

|

Unit of measure

|

Residue combustion furnaces

|

|---|---|---|

|

Gas volume

|

m³/h

|

50 – 150,000

|

|

Gas temperature

|

°C

|

180 – 240

|

|

Type of dust

|

|

Fly ash

|

|

Raw gas dust content

|

g/m³

|

5

|

|

Residual dust content

|

mg/m³

|

< 5

|

|

Cleaning

|

|

online filter

|

|

Filter medium

|

|

Glass / Polytetrafluoroethylene

|

|

Sorbent

|

|

Calcium hydroxide

|