Waste Disposal

Offices

HEADQUARTER

Germany

-

Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REGIONAL OFFICE

Great Britain

-

Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REGIONAL OFFICE

United Arab Emirates

-

Intensive Filter Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Intensiv Filter Himenviro: Waste Disposal Industry Environmental Solutions

Home » Industries » Waste Disposal

Today mainly dry and quasi-dry methods, the separation efficiency of which is significantly better than the currently applicable limit values, are used in the field of waste incineration. In this, fabric filters play an important role in the overall process and, when used with sorbent mixtures, allow for simultaneous separation of acidic gas pollutants, unburnt aromatic compounds, dioxins and furans, heavy metals, and dust. Unlike waste, sewage sludge cannot be avoided – on the contrary. Better wastewater purification naturally produces more sewage sludge. In the Federal Republic of Germany approx. 10-15% of communal sewage sludge is incinerated. It is frequently highly contaminated with substances that mainly get into the waste gas when treated thermally. Usually, sewage sludge incineration plants are equipped with multi-stage gas cleaning installations for separating bags of dust and acidic harmful gases and for reducing the number of nitric oxides.

Application

- Painting & spraying booths

- Industrial Finishing

- Coating Processes

- Chemical Processes

- Plastic & Rubber Production

- Pharmaceutical Processes

- Wastewater pound vapors & gases

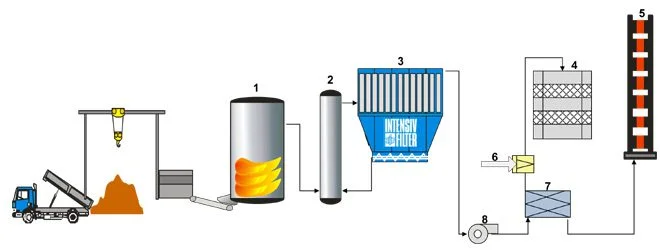

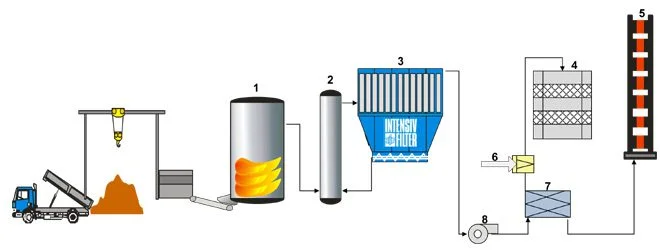

Process

- 1. Incineration plant

- 2. Reactor

- 3. Filter for reactor

- 4. Denox plant

- 5.Chimney

- 6. Natural gas

- 7. Heat exchanger

- 8. Ventilator

Required specifications

Waste disposal process of waste incineration

|

Typical design data

|

Unit of measure

|

Waste incineration

|

|---|---|---|

|

Gas volume

|

m³/h

|

60,000-100,000

|

|

Gas temperature

|

°C

|

140 – 180

|

|

Type of dust

|

|

Fly ash

|

|

Residual dust content

|

g/m³

|

< 10

|

|

Raw gas dust content

|

mg/m³

|

5 – 10

|

|

Cleaning

|

|

online

|

|

Filter medium

|

|

|

|

Explosion protected design

|

|

not necessary

|

|

Sorbent

|

Calcium hydroxide, furnace coke,

active carbon, sodium bicarbonate |

|

Filter title IFJCC

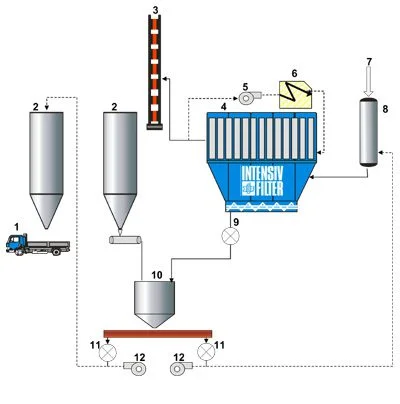

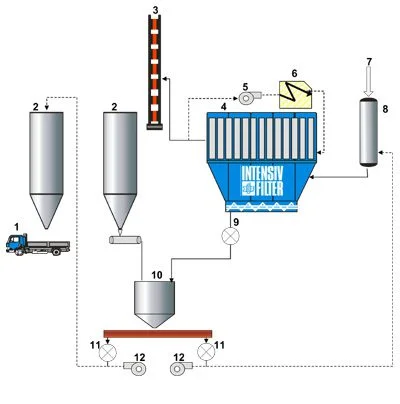

Waste disposal process of Sewage Sludge incineration

- 1. Terminal

- 2. Silo

- 3. Chimney

- 4. Filter for reactor

- 5.Recirculating air fan

- 6.Heater battery

- 7. Waste gas from incineration plants

- 8. Ventilator

- 9. Receiver tank

- 10. Receiver tank

- 11. Blow-through valve

- 12. Air dryer