Offices

HEADQUARTER

Germany

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REGIONAL OFFICE

Great Britain

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REGIONAL OFFICE

United Arab Emirates

- Intensive Filter Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Chemical Industry Air and Dust Filtration Solutions

The chemical industry involves processes that often generate hazardous airborne particles, vapors, and fumes that can impact worker safety, product quality, and environmental sustainability. Our air and dust filtration solutions are specifically designed to address the unique challenges of chemical manufacturing, capturing particulate matter, gases, and chemical fumes at critical points throughout production. From raw material handling to packaging, our systems are built to ensure compliance with strict regulatory standards, protect workers from exposure, and safeguard the environment while maintaining operational efficiency.

Dust Filtration Process in the Chemical Industry

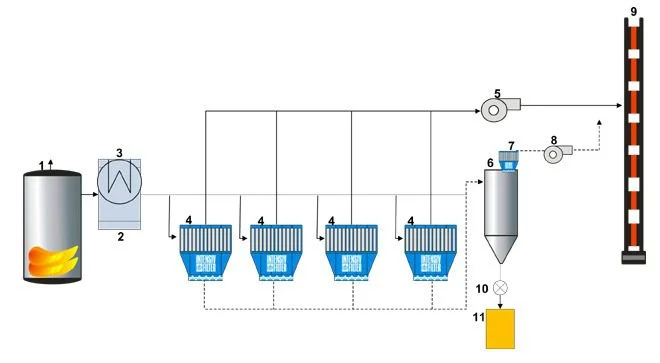

Climate change and climate protection are playing an increasingly important role. Therefore the various business units of the chemical industry have committed themselves to reducing emissions, for instance (“Responsible Care”). Based on the example of a residue combustion plant in a chemical company, dust featuring difficult cleaning properties is removed from the system. A filtering precipitator is used for waste gas dust removal.

Filter for residue combustion furnace

Filter for residue combustion furnace

Filter for residue combustion furnace

Filter for residue combustion furnace

Silo filter

- 1. Combustion plant

- 2. Steam boiler

- 3. Heat exchanger

- 4. Filter for residue combustion furnace

- 5. Induced draft fan

- 6. Silo

- 7. Silo filter

- 8. Conveyor ventilator

- 9. Chimney

- 10. Dust discharge

- 11. Disposal

Required specifications

Typical design data | Residue combustion furnaces |

|---|---|

Gas volume | 50 – 150,000 |

Gas temperature | 180 – 240 |

Type of dust | Fly ash |

Raw gas dust content | 5 |

Residual dust content | < 5 |

Cleaning | online filter |

Filter medium | Glass / Polytetrafluoroethylene |

Sorbent | Calcium hydroxide |

Applications for Chemical Industry Dust Control

Captures airborne dust and fumes generated during chemical reactions, mixing, and other manufacturing processes, reducing exposure to harmful chemicals.

Controls dust during the storage, handling, and transfer of raw chemicals, preventing airborne contamination and ensuring safety.

Reduces exposure to volatile organic compounds (VOCs) and other hazardous particles during chemical reaction and mixing stages, ensuring a safer production environment.

Minimizes dust and fume emissions during packaging and distribution processes to ensure finished products remain contaminant-free.

Regulatory Landscape for Dust Control |

|---|

Air Quality Standards Compliance |

Worker Health & Safety Compliance |

Fire & Explosion Hazard Prevention |

Environmental Protection Compliance |

Real-Time Emission Monitoring |

Heat & Chemical Resistance |

Reduced Downtime and Maintenance Costs |

Product Integrity and Consistency |

Lower Operational Costs |

Dust Control Challenges |

|---|

Handling Hazardous Dust and Vapors |

Managing Respiratory Risks for Workers |

Meeting Strict Environmental Regulations |

Combustion and Explosion Hazards |

Maintaining Product Quality and Purity |

Corrosive Materials and Extreme Temperatures |

Equipment Wear and Tear |

High Dust and Fume Generation |

Downtime Due to System Maintenance |

Key Considerations for Effective Dust Control |

|---|

Efficient Dust and Fume Capture |

Chemical and Heat Resistance |

Optimized Airflow and Pressure Management |

Advanced Filtration Materials |

Routine Maintenance & Inspections |

Compliance with Regulatory Standards |

Customized Filtration Solutions |

Risk Mitigation for Hazardous Chemicals |

Flexible System Configurations |

Connect with us for Expert Consultation

Explore Our Other Services !

Frequently Asked Questions

Filtration systems used in chemical processing include baghouse filters for dry dust collection, electrostatic precipitators for handling fine particulate emissions, wet scrubbers for controlling acid gases and vapors, and cartridge filters for smaller volumes or precision air quality control. In processes involving high temperatures or aggressive chemicals, hot gas filtration systems using sintered metal media are also applied. Each solution is selected based on the nature of the emissions, the process conditions, and environmental compliance requirements.

Filtration systems in chemical manufacturing enhance air quality by effectively capturing and removing particulate matter and pollutants generated during processing. By reducing emissions, these systems help facilities comply with environmental regulations and standards, thereby minimizing their environmental impact and promoting a safer workplace.

ESPs offer high efficiency in removing fine particles, achieving up to 99% efficiency, which is particularly beneficial in chemical production where flue gas emissions often contain fine dust particles. They are capable of handling large gas volumes and operate effectively at high temperatures. Additionally, ESPs have relatively low pressure drops, resulting in lower energy consumption during operation.