Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

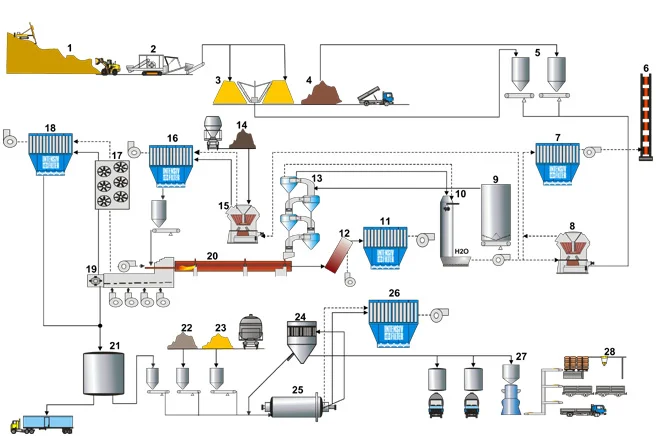

Bag Filters Use Cases in Cement Production Process

Outer filter

Spray dryer

CIP filter

External fluidized bed

Filling

- 1. Quarry

- 2. Crusher plant

- 3. Raw material homogenization

- 4. Aggregates

- 5. Raw mill feeding silo

- 6. Main stack

- 7. Bag filter for kiln-/raw mill

- 8. Vertical raw mill

- 9. Raw material feeding silo

- 10. Gas conditioning tower

- 11. Bag filter for alkali bypass

- 12. Bypass mixing chamber

- 13. Cyclone pre-heater

- 14. Raw coal

- 15. Vertical coal grinding mill

- 16. Bag filter for coal grinding plant

- 17. Tubular cooler

- 18. Bag filter for clinker cooler

- 19. Clinker cooler

- 20. Rotary kiln

- 21. Clinker silo

- 22. Gypsum

- 23. Minerals

- 24. Separator

- 25. Cement finish mill

- 26. Bag filter for cement finish mill

- 27. Packaging plant

- 28. Palletization plant

Required Specification

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Typical design data | Kiln-/raw mill |

|---|---|

Gas volume | < 1,200,000 |

Gas temperature | 85 – 110 compound / < 250 direct |

Type of dust | CaCO3, CaO |

Residual dust content | < 550 |

Raw gas dust content | < 10 |

Cleaning | online / offline |

Filter medium | PEA, NX, PPS, PI, GL/PTFE |

Typical design data | Alkali bypass |

|---|---|

Gas volume | < 800,000 |

Gas temperature | < 250 |

Type of dust | CaCO3, CaO, Alkali |

Residual dust content | < 25 |

Raw gas dust content | < 10 |

Cleaning | offline |

Filter medium | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Typical design data | Coal mill |

|---|---|

Gas volume | < 450,000 |

Gas temperature | 80 – 110 |

Type of dust | Coal |

Residual dust content | < 250 |

Raw gas dust content | < 10 |

Cleaning | online |

Filter medium | PEA / PAN |

Typical design data | Tubular cooler |

|---|---|

Gas volume | < 1,600,000 |

Gas temperature in | 250 – 350 |

Gas temperature out | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Typical design data | Clinker cooler |

|---|---|

Gas volume | < 800,000 |

Gas temperature | 120 – 180 |

Type of dust | Clinker |

Raw gas dust content | 10 – 30 |

Residual dust content | < 10 |

Cleaning | online |

Filter medium | PE / NX /PI |

Typical design data | Cement finish mill |

|---|---|

Gas volume | < 300,000 |

Gas temperature | 80 – 110 |

Type of dust | Cement, slag |

Raw gas dust content | < 350 |

Residual dust content | < 10 |

Cleaning | online / offline |

Filter medium | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Controls dust generated from high-energy crushing and grinding processes, capturing fine particulate matter to prevent it from escaping into the atmosphere.

Reduces emissions from kiln processes where raw materials are heated, controlling dust and other airborne particles released during cement production.

Captures dust during the transport of bulk materials, such as limestone and clinker, to prevent particle release in storage and conveying stages.

Minimizes dust emissions in product packaging and storage areas, ensuring that finished products are packed and stored in a contaminant-free environment.

Regulatory Landscape for Dust Control |

|---|

Air Quality Standards |

Worker Health and Safety |

Fire and Explosion Prevention |

Environmental Protection |

Emission Monitoring and Reporting |

Energy Efficiency |

Waste Management |

Product Quality and Consistency |

Reduced Downtime and Maintenance Costs |

Dust Control Challenges |

|---|

High Dust Levels |

Worker Health Risks |

Environmental Compliance |

Fire and Explosion Hazards |

Product Quality Concerns |

Equipment Wear and Tear |

Cross-Contamination |

Air Quality Compliance |

Microbial Growth |

Key Considerations for Effective Dust Control |

|---|

Implement Effective Dust Capture Systems |

Proper Airflow and Pressure Control |

Temperature and Moisture Management |

High-Efficiency Filtration Systems |

Regular Maintenance and Inspection |

Adherence to Industry Standards |

Frequent Assessment of Dust Control System |

Process-Specific Adaptations |

Risk Assessment and Mitigation |

Connect with us for Expert Consultation

Explore Our Other Services !

Frequently Asked Questions

In the cement industry, effective filtration solutions are essential for controlling dust emissions and ensuring environmental compliance. Commonly used filtration systems include baghouse filters, which utilize fabric filter bags to capture fine particles from various processes such as kilns, mills, and material handling. These filters are favored for their high efficiency in removing particulate matter. Additionally, advanced filtration solutions, such as those offered by Micronics, are designed to meet the unique demands of the cement industry, ensuring compliance with environmental regulations and enhancing operational efficiency.

Filtration systems improve efficiency in cement production by effectively capturing dust and particulate matter, reducing equipment wear and preventing blockages. This ensures smooth operation, minimizes downtime, and enhances product quality by preventing contamination. Proper dust control also helps maintain regulatory compliance, reducing the risk of fines and environmental issues. Additionally, efficient filtration systems contribute to energy savings by optimizing airflow and reducing pressure drops in the system.

Advanced filtration systems in cement production help reduce air pollution by capturing fine dust particles and minimizing emissions of harmful pollutants. They improve air quality, ensuring compliance with environmental regulations and reducing the industry’s carbon footprint. By enhancing dust control, these systems also contribute to worker health and safety. Additionally, they support sustainability by enabling the recovery and reuse of raw materials, reducing waste, and optimizing energy efficiency in cement manufacturing processes.