Offices

HEADQUARTER

Germany

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REGIONAL OFFICE

Great Britain

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REGIONAL OFFICE

United Arab Emirates

- Intensive Filter Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Waste Disposal Air and Dust Filtration Solutions

The waste disposal industry involves complex processes such as waste collection, transfer, treatment, incineration, and recycling—all of which generate significant dust, harmful particulates, and hazardous emissions. These emissions, if not properly controlled, pose risks to worker health, regulatory compliance, and environmental safety. Our advanced air and dust filtration solutions are engineered to address the challenges of waste management, capturing fine particles and pollutants at every critical stage. With customized systems, we help waste disposal facilities maintain cleaner work environments, reduce harmful emissions, and meet stringent environmental standards.

Dust Filtration Process in the Waste Disposal Industry

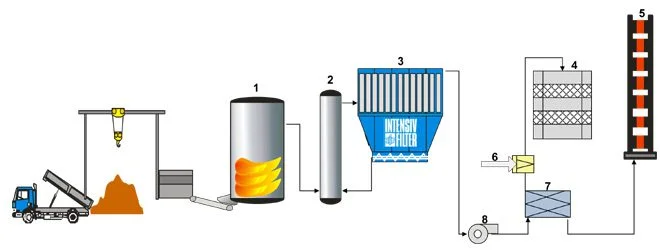

Filter for reactor

- 1. Incineration plant

- 2. Reactor

- 3. Filter for reactor

- 4. Denox plant

- 5.Chimney

- 6. Natural gas

- 7. Heat exchanger

- 8. Ventilator

Required specifications

Waste disposal process of waste incineration

Typical design data | Waste incineration |

|---|---|

Gas volume | 60,000-100,000 |

Gas temperature | 140 – 180 |

Type of dust | Fly ash |

Residual dust content | < 10 |

Raw gas dust content | 5 – 10 |

Cleaning | online |

Filter medium | |

Explosion protected design | not necessary |

Sorbent | Calcium hydroxide, furnace coke, active carbon, sodium bicarbonate |

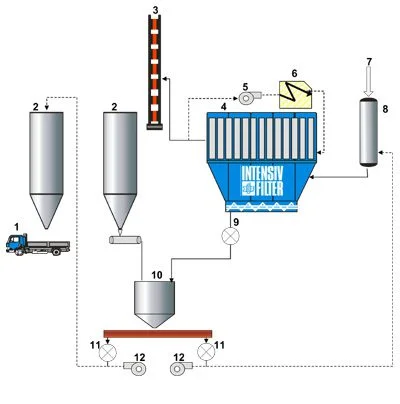

Waste disposal process of Sewage Sludge incineration

- 1. Terminal

- 2. Silo

- 3. Chimney

- 4. Filter for reactor

- 5.Recirculating air fan

- 6.Heater battery

- 7. Waste gas from incineration plants

- 8. Ventilator

- 9. Receiver tank

- 10. Receiver tank

- 11. Blow-through valve

- 12. Air dryer

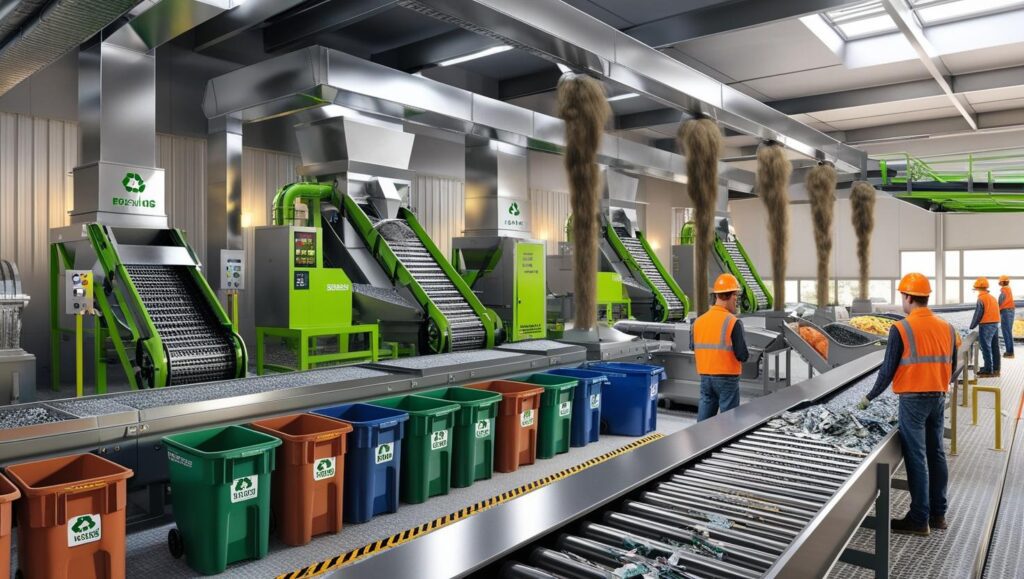

Applications for Waste Disposal Dust Control

Controls dust generated during waste collection and sorting operations, minimizing airborne particles that may contain contaminants.

Captures dust and odor emissions at transfer points during bulk waste movement, improving air quality in transfer stations.

Mitigates emissions from high-temperature incinerators, reducing fine particulate matter, hazardous gases, and harmful byproducts.

Filters dust generated during sorting, shredding, and recycling of materials such as metals, plastics, and glass.

Regulatory Landscape for Dust Control |

|---|

Air Quality Standards Compliance |

Worker Health & Safety Compliance |

Hazardous Emissions Management |

Combustion and Explosion Prevention |

Odor Control Regulations |

Sustainable Environmental Practices |

Emission Monitoring and Reporting |

Waste Management Regulations |

Energy Efficiency Guidelines |

Dust Control Challenges |

|---|

High Dust Volume |

Health Risks |

Odor Emissions |

Regulatory Compliance |

Fire and Explosion Hazards |

Equipment Wear and Tear |

Hazardous Waste Handling |

Environmental Impact |

Cross-Contamination |

Key Considerations for Effective Dust Control |

|---|

Advanced Dust Collection Systems |

Odor and VOC Control |

Temperature-Resistant Filtration |

Bioaerosol Filtration |

Real-Time Emission Monitoring |

Hazardous Dust Containment |

Regular Maintenance and Inspection |

Energy-Efficient Solutions |

Custom Plant Adaptations |

Connect with us for Expert Consultation

Explore Our Other Services !

Frequently Asked Questions

Air and dust filtration is essential in waste disposal environments to capture harmful particles, gases, and odors released during the handling, incineration, or processing of waste. These pollutants can pose serious health and environmental risks if left untreated. Effective filtration systems ensure regulatory compliance, protect worker safety, and contribute to cleaner operations.

A variety of filtration systems are used based on the waste type and treatment process. Common solutions include baghouse filters for capturing fine particulates, wet scrubbers for removing acidic gases and soluble compounds, and activated carbon systems for odor control. Cyclone separators are often used to manage larger particles before fine filtration takes place. Air-to-air heat exchangers can also be used for energy recovery in waste incineration setups.

Filtration systems help reduce the emission of dust, toxic gases, and volatile compounds, allowing facilities to meet local and international environmental standards. They play a vital role in keeping emissions below permissible limits and are necessary for gaining environmental clearances and maintaining public trust.