filter media

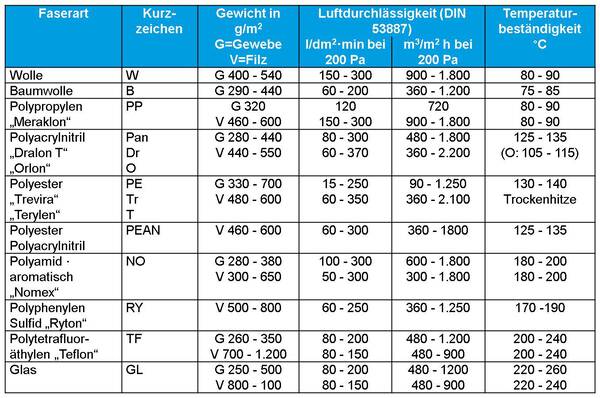

The filter medium takes over the physical task of gas-solid separation and must have a corresponding mechanical, thermal, and chemical resistance in addition to the required high dust retention capacity. Filter media do the dedicated work of the filter systems. They are sensitive structures made of fine natural or synthetic fibers. Depending on the area of application, they are exposed to different temperatures, neutral, dry, moist, or chemically aggressive gases, fine or coarse dust with different material properties that are harmless in terms of filter technology, or abrasive dust. The choice of fiber type depends on the temperature, humidity and chemical composition of the gas to be cleaned, as well as the properties of the dust. In addition, the fiber count is an important criterion. The finer the fiber, the larger the specific surface area and, as a rule, the separation effect is improved.

filter material

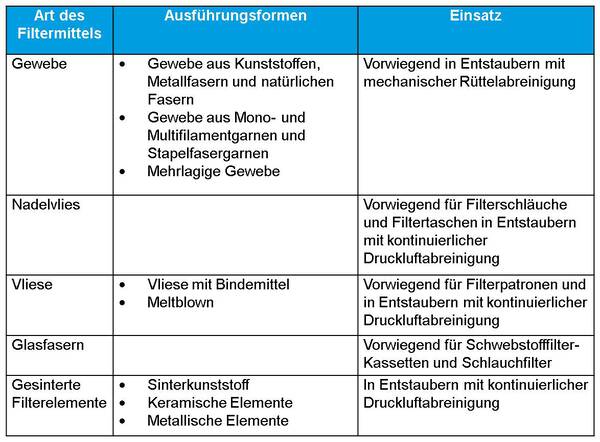

An important part of the regenerable filter is the material of the filter medium. Filter media for surface filtration can be made of fibers, plastic bodies, or mixed forms. Filter media made of fibers are the most common.

An ideal filter medium must meet the following requirements:

- Dimensional and chemical stability as well as the highest possible temperature resistance.

- Bending and tensile strength, so that no damage occurs due to mechanical movement during cleaning.

- Optimum air permeability with the highest possible retention capacity for the finest dust.

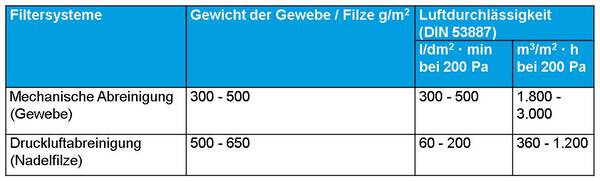

Classification and selection of fabric and needle-felt filter media in dry filtration according to filter systems

Manufacture of filter materials

Filter materials are made into filter hoses, filter bags, filter cartridges, filter lamellae, and filter cassettes. These are either sewn, welded, glued, or poured together.

The seams can be sealed if necessary. The floors and the sealing units at the head are either sewn in or cast in plastic. Options for sealing the filter hoses to the base plate are:

- sewn-in snap ring with double bead

- sewn-in ring

- sewn-on sealing felt

Technical data of filter media

(according to VDI guideline 3677 and VDI guideline memory filter)