Offices

HEADQUARTER

Germany

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REGIONAL OFFICE

Great Britain

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REGIONAL OFFICE

United Arab Emirates

- Intensive Filter Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAL OFFICE

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

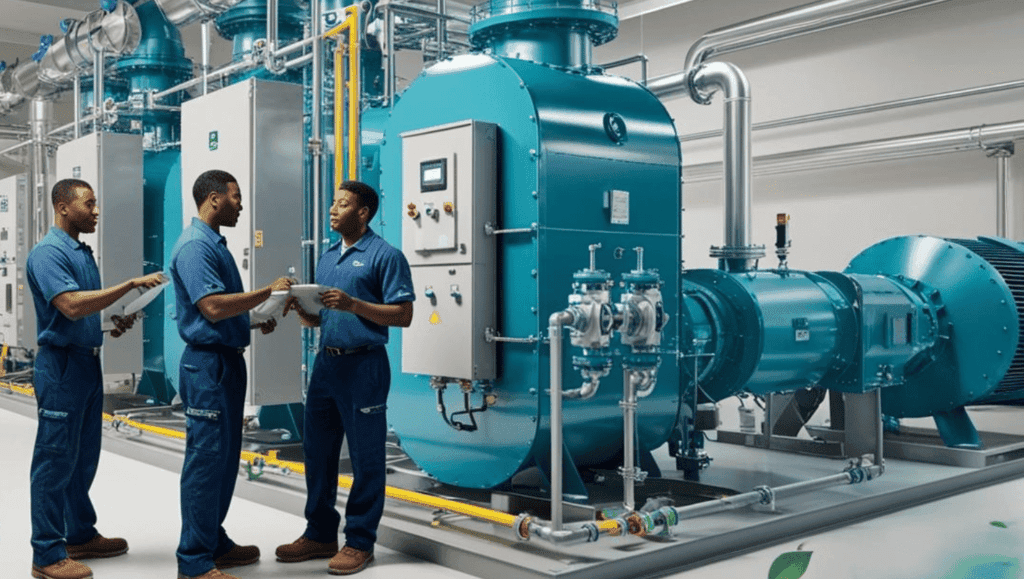

Flue-Gas Desulfurization (FGD) System for Coal-Fired Power Plants

The Flue-Gas Desulfurization (FGD) system is a crucial technology designed to reduce sulfur dioxide (SO2) emissions from coal-fired power plants. SO2 is a harmful pollutant that contributes to air quality issues, acid rain, and various health problems. The FGD process involves removing sulfur from the exhaust gases before they are released into the atmosphere. By utilizing advanced scrubbing technologies, FGD systems help coal plants meet environmental standards, ensuring cleaner emissions and improved air quality. FGD systems are a vital solution for the reduction of sulfur-related pollutants, offering both environmental protection and regulatory compliance.

Our Products Application for Operational Benefits

- Efficient SO2 Management: The FGD system effectively captures sulfur dioxide from flue gases, ensuring optimal air quality and regulatory compliance.

- Cost-Effective Operation: FGD technology minimizes operational costs by reducing energy consumption and maintenance needs.

- Reduced Environmental Footprint: Contributes to the plant’s overall environmental sustainability by mitigating harmful emissions.

- Minimal Downtime: The system operates with minimal maintenance and is designed to maximize uptime, keeping the plant running smoothly.

- Compliance with Global Standards: Ensures compliance with a range of global emissions standards, protecting the plant from potential fines or closures.

Our Products Application for Solution in Place Filter

The FGD system can be seamlessly integrated into existing coal-fired power plants.

Can be installed as a new system or retrofitted into older plants to enhance sulfur control.

Installed without major disruptions to plant operations, ensuring continuous energy production.

The system can be upgraded or modified as new environmental regulations come into play.

Applications for Flue-Gas Desulfurization |

|---|

Coal-Fired Power Plants |

Industrial Boilers |

Waste-to-Energy Plants |

Refineries |

Steel Manufacturing Plants |

Cement Manufacturing |

Chemical Processing Plants |

Petrochemical Plants |

Mining Operations |

Key Features and Benefits |

|---|

High SO2 Removal Efficiency |

Versatile Scrubbing Technologies |

Cost-Effective |

Adaptability |

Long-Term Reliability |

Environmentally Friendly |

Regulatory Compliance |

Improved Air Quality |

Energy Efficient |

Advantages |

|---|

Reduces Harmful Emissions |

High Efficiency |

Regulatory Compliance |

Environmental Protection |

Improved Plant Longevity |

Cost Savings |

Sustainability |

Enhances Public Health |

Supports Clean Energy Transition |

Connect with us for Expert Consultation

Explore Our Other Services !

Frequently Asked Questions

Flue Gas Desulphurization is a technology used to remove sulfur dioxide (SO₂) from industrial exhaust gases produced during fuel combustion in power, cement, chemical, and waste-to-energy plants. FGD systems prevent acid gas emissions from entering the atmosphere and mitigate environmental and health risks.

There are three main FGD methods: wet scrubbing, spray-dry (semi‑dry) scrubbing, and dry sorbent injection. In wet systems, sulfur dioxide is absorbed using a limestone or lime slurry and the reaction produces gypsum, which can often be reused. Spray-dry or semi-dry systems use lime-based sorbents with no wastewater but generate dry by-products, while dry injection systems introduce powdered sorbents directly into flue gas for removal of SO₂ without liquid handling.

Wet FGD achieves the highest SO₂ removal rates (typically over 90 %) and can produce reusable gypsum. However, it has higher installation and operational costs, requires wastewater treatment, and can lead to corrosion if not managed correctly. Semi-dry systems offer lower water use, smaller footprint, and reduced waste handling, but are somewhat less efficient. Dry injection methods are simple and flexible, but efficiency can vary based on process conditions.