Top dust collector companies in the world play a critical role in shaping modern industries, where clean air, emission control, and sustainability are non-negotiable. From cement plants and steel mills to power generation and food processing facilities, effective dust collection systems are no longer a choice but a necessity. Governments enforce strict environmental regulations, energy costs continue to rise, and industries face increasing pressure to adopt eco-friendly practices. In this competitive landscape, only the most advanced and reliable dust collectors can help organizations remain compliant, efficient, and future-ready.

Among these global leaders, Intensiv-Filter Himenviro has emerged as a pioneer in dust collection technology. Established in 1922 in Germany, the company brings over a century of engineering expertise to industries worldwide. With a strong global footprint across Europe, Asia, and beyond, Intensiv-Filter Himenviro is trusted for delivering customized, high-performance dust collection solutions that ensure cleaner operations and contribute to a sustainable future. Guided by its principle — “We Care for Air” — the company continues to innovate and set benchmarks in air pollution control technology.

Unlike many companies that offer standard solutions, Intensiv-Filter Himenviro focuses on tailor-made designs that meet the unique needs of each industry. Its advanced dust collection systems, including Reverse Air Bag Houses, Fabric Filters, Hybrid Electrostatic Filters, and Gas Cleaning Plants, are engineered for durability, energy efficiency, and minimal maintenance. This commitment to excellence positions Intensiv-Filter Himenviro not just as one of the top dust collector companies in the world, but as a global leader shaping the future of air filtration.

A Legacy of Innovation and Global Reach

Founded over a century ago, Intensiv-Filter Himenviro has grown into one of the most trusted and widely recognized names in industrial air filtration. Since its inception in 1922 in Germany, the company has expanded its global presence significantly. It now serves customers across more than 110 countries, delivers over 70,000 installations worldwide, and has successfully completed over 400 projects—a testament to its broad reach and technical mastery.

Its global network includes a headquarters in Velbert, Germany, and regional subsidiaries and offices in the United Kingdom, India (Noida), the United Arab Emirates, as well as a presence in France, Brazil, Korea, Austria, among others across Asia-Pacific, Africa, the Middle East, the USA, and South America.

Together, this global presence and deep technical expertise enable Intensiv-Filter Himenviro to respond promptly and effectively to diverse industrial requirements—making it a true leader among top dust collector companies worldwide.

Industries We Serve

One of the key reasons Intensiv-Filter Himenviro is consistently recognized among the top dust collector companies worldwide is its proven capability to design and engineer solutions that are not only effective but also industry-specific. Dust is never uniform — its particle size, composition, abrasiveness, moisture content, and explosiveness differ drastically from one process to another. This means that every industry demands filtration systems customized to its operational challenges, regulatory requirements, and sustainability goals.

Over the decades, Intensiv-Filter Himenviro has successfully delivered tailored solutions across a wide range of industries:

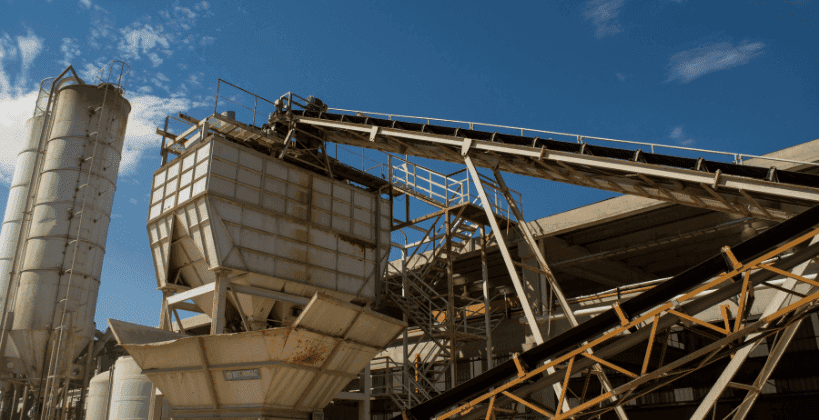

Cement, Lime, and Gypsum: Known for producing some of the heaviest dust loads, cement plants generate dust from kilns, clinker coolers, mills, and material handling systems. Intensiv-Filter Himenviro designs high-efficiency baghouse and electrostatic precipitator systems capable of continuous operation in extreme environments, ensuring compliance with strict emission norms while maintaining long-term reliability.

Steel, Iron, and Non-Ferrous Metals: Metallurgical processes release dust that is often hot, abrasive, and chemically aggressive. From primary smelting to secondary dedusting and casting operations, the company’s filtration systems are built to handle ultra-high temperatures and abrasive dust, prolonging filter life and safeguarding worker health while reducing energy consumption.

Food and Beverage Processing: Dust in this industry, while less abrasive, poses challenges related to hygiene, contamination, and product safety. Intensiv-Filter Himenviro offers FDA-compliant and food-grade filter materials that ensure air quality, prevent cross-contamination, and protect both the product and workforce — critical in sugar mills, grain processing, spice production, and dairy operations.

Chemicals and Pharmaceuticals: Fine powders and hazardous particulate matter require precision filtration to protect workers and ensure clean air in controlled environments. Intensiv-Filter Himenviro provides explosion-proof, ATEX-compliant dust collectors with advanced safety features to meet the highest industry and environmental standards.

Energy and Power Generation: Boilers, furnaces, and turbines release fly ash, unburnt carbon, and fine particulate emissions. The company’s systems are designed to handle massive air volumes while ensuring low pressure drop, high efficiency, and minimal downtime, supporting plants in meeting global emission standards such as Euro norms and US EPA guidelines.

Waste Disposal and Recycling: Waste treatment plants generate complex mixtures of dust containing heavy metals, toxins, and fine particulates. Intensiv-Filter Himenviro offers filtration systems with corrosion-resistant designs and advanced cleaning technology that ensure consistent operation even under fluctuating load conditions.

Glass and Mineral Products: The production of glass, ceramics, and other mineral products involves extreme heat and fine silica dust — known to be hazardous to health. The company’s filtration solutions withstand temperatures up to 500°C and offer specialized coatings that resist wear, ensuring longevity and worker safety.

Pulp & Paper Industry: Dust generated during wood processing, pulping, and paper finishing stages requires filtration systems that can adapt to both fibrous particles and sticky dust. Intensiv-Filter Himenviro provides tailored solutions that maintain plant hygiene while reducing fire and explosion risks.

Automotive & Paint Shops: In vehicle manufacturing, dust and overspray particles can impact surface quality and safety. The company’s filtration systems ensure clean, controlled environments that improve product finish and compliance with occupational safety standards.

Across all these sectors, Intensiv-Filter Himenviro’s strength lies in understanding the client’s unique processes and designing solutions that go beyond regulatory compliance. Each project is executed with a focus on energy efficiency, operational reliability, and long service life, making it a trusted partner for industries seeking clean air solutions that safeguard both people and the planet.

Comprehensive Dust Collection Solutions

Intensiv-Filter Himenviro offers far more than just dust collection equipment. It delivers end-to-end system solutions, covering design, engineering, turnkey execution, technical support, and after-sales service. Whether it’s a new greenfield installation or the modernization of an existing facility, every project is engineered to ensure optimized performance across the entire lifecycle of the system.

The company’s approach is built on three core pillars:

- Reducing Energy Consumption – By integrating advanced pulse-jet cleaning technology and optimized fan designs, energy savings of 15–20% can typically be achieved compared to conventional systems.

- Extending Filter Life – Special filter media and intelligent cleaning controls extend bag life to 5–7 years, minimizing maintenance costs and downtime.

- Achieving the Lowest Emissions – Systems are designed to meet stringent standards such as <10 mg/Nm³ dust emissions, complying with EU and US EPA norms for clean air.

Each solution is tailored to plant-specific needs, ensuring stable pressure drop, minimal compressed air usage, and continuous operation even under heavy loads. From initial consultation and pilot studies to commissioning and lifecycle support, Intensiv-Filter Himenviro ensures that its clients benefit from sustainable, reliable, and regulation-compliant air pollution control for decades.

Our Product Portfolio

At the heart of Intensiv-Filter Himenviro’s global success lies its diverse, innovative, and field-proven range of dust collection products. Built on decades of engineering expertise and continuous R&D, the company’s portfolio is designed to meet the demands of both small-scale facilities and mega-industrial complexes. Each solution combines durability, efficiency, and sustainability, ensuring long-term performance under the toughest operating conditions.

Bag Filters

A cornerstone of industrial air filtration, Intensiv-Filter Himenviro’s bag filters are engineered for 99.9% dust separation efficiency, making them one of the most reliable solutions for air pollution control. Available in multiple designs — including top- and bottom-load configurations — these filters are designed to withstand extreme temperatures, abrasive dust, and continuous duty cycles, ensuring consistent operation across industries like cement, steel, power, and chemicals.

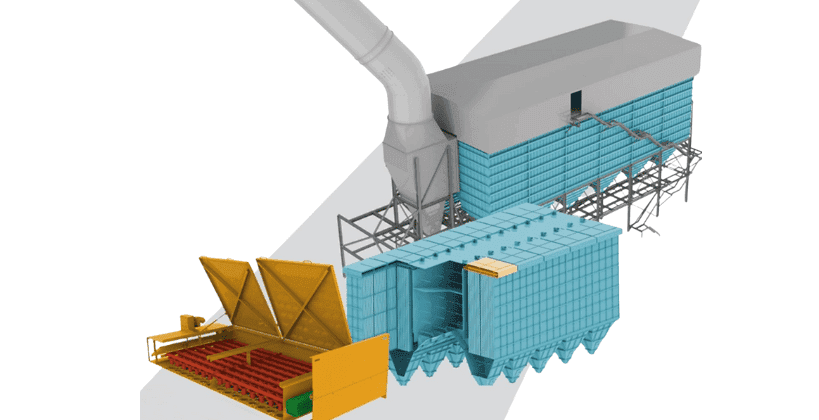

CombiJet

The CombiJet system represents modular flexibility at its finest. With welded or bolted construction, it can be tailored to site-specific conditions, offering filter surfaces ranging from 25 m² to over 10,000 m². Depending on process needs, cleaning can be performed in online, offline, or semi-offline modes, making it a versatile solution for industries that require adaptability without compromising on efficiency.

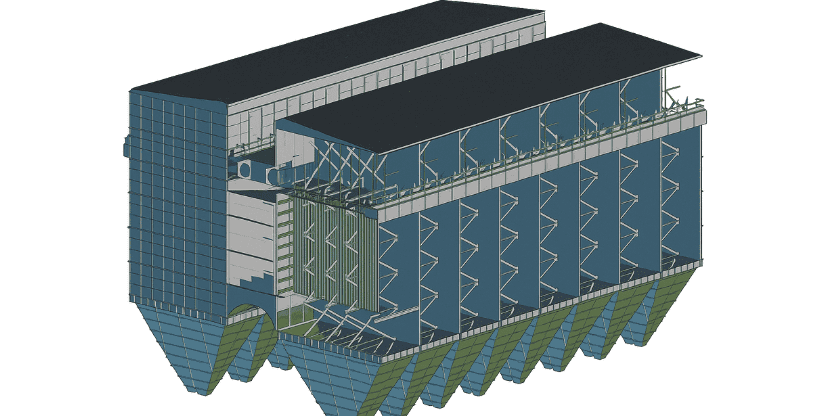

ProJet mega®

The flagship solution for large-scale applications, the ProJet mega® is widely recognized as a powerhouse in dust collection technology. Designed for cement, lime, and power industries, it supports bag lengths up to 12 meters and air volume flows exceeding 2,000,000 m³/h. With its modular design and ability to handle massive process gas volumes, the ProJet mega® offers cost-effective scalability, delivering performance that ensures compliance with the world’s most stringent emission standards.

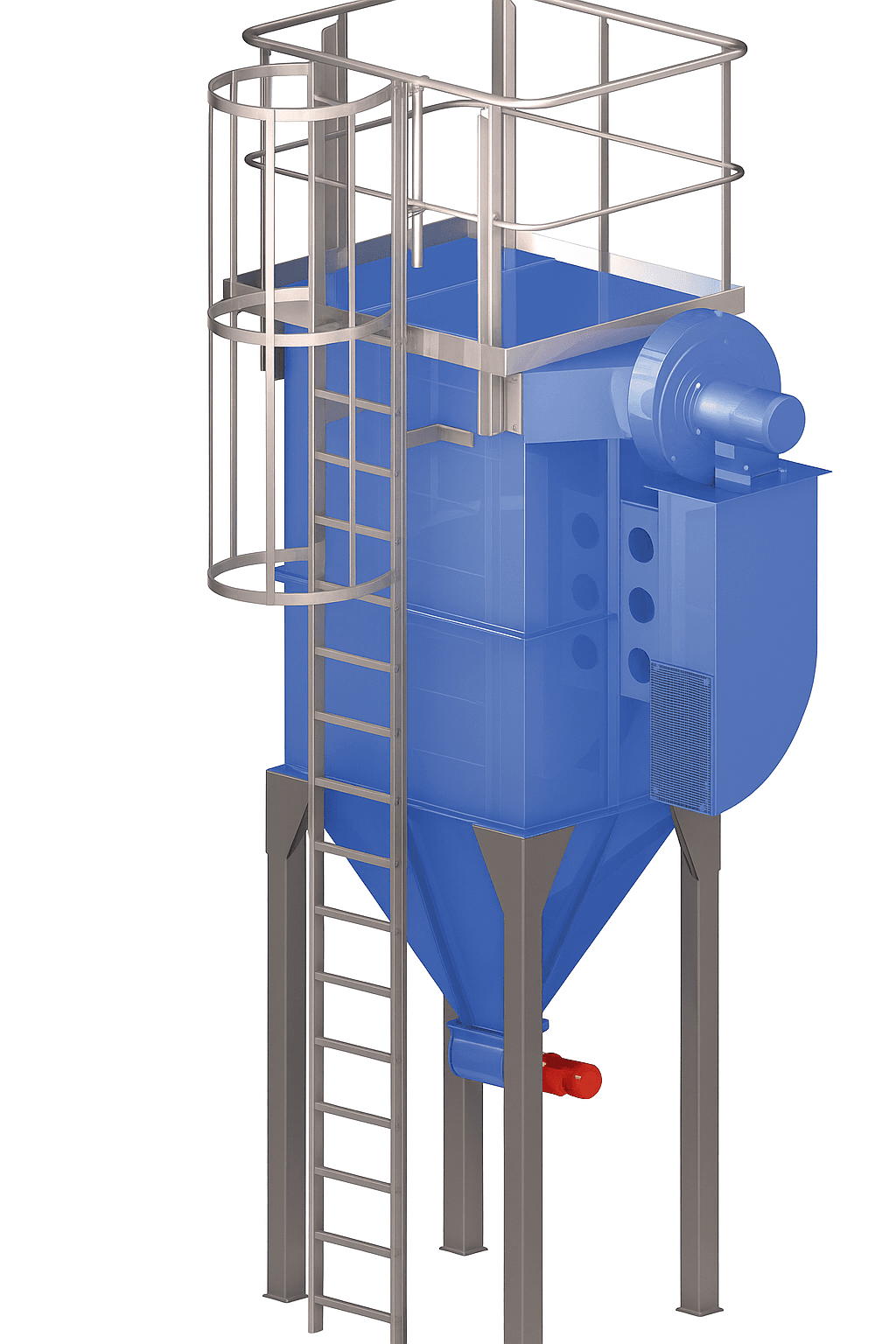

ProJet smart®

Compact yet robust, the ProJet smart® is the go-to choice for medium-scale industries seeking high-performance dust collection at a competitive cost. Pre-engineered as ready-to-connect series filters, it ensures fast installation, minimal commissioning time, and reliable operation. This makes it ideal for industries such as food processing, chemicals, and small power units, where space and cost optimization are critical.

ProJet CIP®

Redefining the future of maintenance efficiency, the ProJet CIP® (Cleaning-in-Place) system integrates cutting-edge cleaning technology into dust collection. With bag lengths up to 8 meters, reduced compressed air usage, and minimal installation components, it dramatically lowers both operational costs and downtime. The use of ProTex® CIP filter media ensures flawless washing, rapid drying, and extended service life, making it especially valuable in industries where hygiene and continuous uptime are essential — such as pharmaceuticals, food, and specialty chemicals.

ProTex® Filter Media

Energy efficiency is embedded into Intensiv-Filter Himenviro’s DNA, and the ProTex® filter media line reflects this commitment. Designed as a low-pressure-drop, high-regeneration solution, ProTex® filters reduce energy consumption, extend bag life, and help industries meet CO₂ reduction goals. By improving regeneration efficiency, these filters ensure stable long-term performance while aligning with global climate sustainability targets.

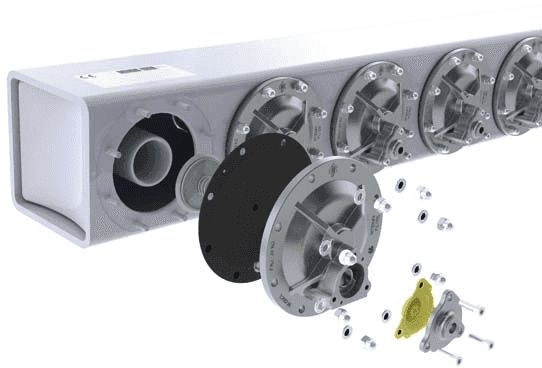

Coanda-Injector System

The Coanda-Injector system is a proprietary innovation that maximizes filter bag cleaning effectiveness while significantly reducing compressed air consumption. By optimizing air-jet distribution, it minimizes wear on filter bags and extends their lifespan, directly contributing to lower operating costs and higher system reliability.

Complete Auxiliary Range

In addition to its core products, Intensiv-Filter Himenviro also provides cyclones, coolers, auxiliary filters, and specialized plant components. This comprehensive offering allows the company to deliver fully integrated solutions, ensuring that every stage of the dust collection process — from gas cooling to fine filtration — is covered with precision and reliability.

Engineering and Innovation

Intensiv-Filter Himenviro stands at the forefront of engineering excellence in industrial dust collection. The company integrates advanced Computational Fluid Dynamics (CFD) simulations, Finite Element Method (FEM) calculations, and state-of-the-art CAD modeling into every stage of product development. These digital tools allow engineers to predict flow patterns, optimize filter housing designs, and assess the structural strength of equipment under varying operating conditions.

To validate designs, Intensiv-Filter Himenviro operates in-house laboratories and pilot-scale test facilities where rigorous trials are carried out. These include assessments of filter media permeability, pulse-jet cleaning efficiency, and thermal resistance under high-temperature flue gas streams (up to 500°C). This continuous R&D ensures that every component—from filter bags and cages to injectors and controllers—performs with maximum reliability in demanding industrial environments.

The company also collaborates with leading universities and research institutes, staying ahead of emerging filtration technologies such as nano-fiber coated media, hybrid electrostatic-fabric systems, and energy-saving pulse cleaning mechanisms. This close link between research and application guarantees that customers benefit from the latest scientific advancements translated into real-world solutions.

Service and Support

At Intensiv-Filter Himenviro, customer support extends far beyond the initial installation. The company provides a comprehensive lifecycle service package designed to keep dust collection systems operating at peak efficiency for decades.

Key offerings include:

- Genuine spare parts supply with guaranteed compatibility and long service life

- Customized maintenance contracts tailored to operational schedules and industry-specific requirements.

- Retrofit and modernization services, upgrading older systems to meet today’s stricter environmental standards without full replacement.

- 24/7 global technical support, ensuring rapid response times and minimal downtime.

By combining proactive maintenance with expert technical guidance, Intensiv-Filter Himenviro ensures that its clients achieve optimized energy consumption, longer filter life, and consistently low emissions, year after year.

Proven Global References

With a legacy spanning more than 100+ years and over 70,000 systems installed worldwide, Intensiv-Filter Himenviro has earned a reputation for reliability across diverse industries. Its portfolio includes:

- Spray dryer de-dusting systems in Germany and Brazil, achieving stable operation in high-moisture environments.

- Secondary de-dusting units for steel plants, reducing particulate emissions during material handling and transfer.

- Kiln and clinker cooler dust collection systems in Sweden consistently meet stringent EU emission limits.

Field results have demonstrated residual dust concentrations as low as 1 mg/m³, far below regulatory requirements. Such performance underscores the company’s commitment to delivering not just compliance, but best-in-class filtration efficiency and sustainability.

These proven global references reflect both the technical expertise and the long-standing trust that leading cement, steel, power, and chemical industries place in Intensiv-Filter Himenviro as their long-term partner in air pollution control.

Sustainability and Climate Responsibility

At a time when industries are under increasing pressure to reduce their environmental footprint, Intensiv-Filter Himenviro stands out for its active contribution to climate protection. Its advanced filter media and energy-saving filter concepts can reduce CO₂ emissions by up to 20–30% compared to conventional systems. By lowering pressure drop across filters and optimizing airflow management, the systems significantly cut fan power consumption, which often accounts for 40–50% of the total energy usage in dust collection processes.

The company’s technologies are designed to ensure compliance with stringent global emission norms such as EU Directive 2010/75/EU (IED) and US EPA standards, often achieving emission levels below 10 mg/Nm³, well under legal limits. By improving filter bag life—often extending replacement intervals by 20–25%—the company not only reduces waste but also minimizes lifecycle costs for its clients.

Why Intensiv-Filter Himenviro Stands at the Forefront

With over 100+ years of expertise, a global presence in more than 110 countries, an installed base of 70,000+ filter systems, and a commitment to innovation, Intensiv-Filter Himenviro rightfully stands among the world’s top dust collector companies. The company is more than a manufacturer; it is a trusted partner for industries seeking long-term, high-efficiency, and compliant air pollution control solutions.

From cement plants processing over 2 million m³/h of dust-laden air to pharmaceutical and food processors requiring hygienic and GMP-compliant solutions, Intensiv-Filter Himenviro has consistently proven its ability to deliver tailor-made systems. Backed by world-class German engineering, sustainable practices, and comprehensive service support, it continues to lead the way in making industrial operations cleaner and greener.

Conclusion

Clean air is the foundation of sustainable industry. As environmental regulations tighten and industries grow more conscious of their impact, the need for advanced dust collection has never been greater. Intensiv-Filter Himenviro GmbH, with its legacy, global expertise, and relentless pursuit of innovation, remains at the forefront of this mission.

For industries seeking a reliable partner in air pollution control, Intensiv-Filter Himenviro is not just a supplier but a global leader committed to delivering cleaner, safer, and more sustainable solutions.