Redefining Air Quality & Operational Safety

For industrial leaders, air quality isn’t just compliance—it’s a strategic advantage. Intensiv Filter Himenviro delivers high-performance dust collection systems designed to protect employees, optimize operations, and ensure regulatory compliance. Our solutions cater to sectors ranging from cement, metals, and mining to food processing, pharmaceuticals, and power generation.

Industrial dust isn’t just an irritant—it poses serious contamination, safety, and productivity risks. Traditional air purifiers can’t keep up with the demands of heavy-duty industrial environments. Intensiv Filter Himenviro systems are engineered to handle high dust loads while maintaining uninterrupted production, safeguarding both people and equipment.

How Our Dust Collectors Deliver Value

At the heart of our solutions is a three-step operational strategy: capture, convey, and collect.

Dust is first captured at the source using precision-engineered hoods or enclosures. This ensures no particulate escapes into the workspace, reducing contamination risks. The captured air is then conveyed through purpose-designed ducts, maintaining optimal air velocity to prevent settling and clogging. Finally, dust is collected efficiently via advanced filtration, centrifugal separation, or electrostatic precipitation. Clean air is either safely recirculated or exhausted, depending on operational needs.

This approach ensures:

- Reduced product contamination – Essential for industries like food, pharmaceuticals, and chemicals, advanced dust collectors prevent cross-contamination and protect product quality.

- Enhanced operational safety – Minimize combustible dust risks, protect employees, and ensure compliance with OSHA, EPA, and other industrial safety regulations.

- Lower maintenance costs – Efficient dust collection reduces equipment downtime, prevents excessive wear, and extends machinery lifespan, boosting overall operational efficiency.

Advanced Dust Collection Technologies

- Fabric Filters / Baghouses – Achieve over 99% efficiency for fine dust removal, designed for continuous industrial operation. Pulse-jet, reverse-air, and shaker designs ensure consistent performance and minimal downtime.

- Cyclone Collectors – Perfect for handling heavy dust loads, these systems use centrifugal force to separate coarse particles efficiently, protecting downstream filters and maintaining stable airflow in demanding environments.

- Electrostatic Precipitators (ESP) – Ideal for ultra-fine dust removal in cement, power, and metallurgical industries. ESPs maintain strict emission standards, safeguard sensitive equipment, and improve overall air quality.

- Wet Scrubbers – Use liquid media to capture dust, excelling with sticky, combustible, or hazardous materials. These systems combine safety with high-efficiency particulate removal, suitable for challenging industrial processes.

- Unit Collectors – Compact and portable, these extract dust directly at the source. Perfect for silos, conveyor transfers, and isolated processing points, they reduce contamination and improve localized air quality.

Ensure Clean Air and Regulatory Compliance Today

Operational & Technical Edge

Selecting the right dust collector is a strategic decision. Intensiv Filter Himenviro solutions are engineered considering:

- Dust characteristics: particle size, moisture, abrasiveness, and combustibility.

- Airflow requirements: optimized air-to-cloth ratios and duct velocity to prevent settling.

- Environmental factors: temperature, chemical exposure, and regulatory compliance.

- Maintenance efficiency: automated cleaning, on-demand monitoring, and minimal downtime.

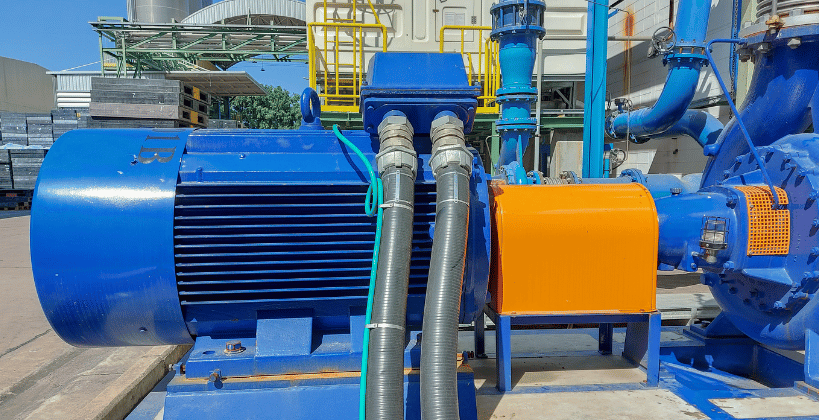

High-efficiency fans and motors reduce energy consumption while ensuring consistent airflow. Integrated monitoring provides real-time insights on filter performance and dust accumulation, enabling predictive maintenance and minimizing operational interruptions.

Industries We Empower

Our systems transform air quality management across multiple industries:

- Cement & Mineral Processing – Baghouses and cyclones efficiently capture dust generated from kilns, crushers, grinding mills, and conveyor systems, ensuring cleaner air and reducing equipment wear.

- Metals & Foundries – ESPs and cyclones are designed to handle heavy, abrasive dust from smelting, casting, and machining operations, protecting machinery and maintaining a safer workplace environment.

- Food & Pharmaceuticals – Fabric filters and wet scrubbers maintain strict hygienic standards, preventing contamination, ensuring product safety, and supporting compliance with industry regulations.

- Power Plants & Chemical Facilities – ESPs and wet scrubbers control fine particulate emissions, protect critical equipment from abrasive dust, and ensure compliance with environmental and safety regulations.

By controlling dust effectively, we enhance workplace safety, regulatory compliance, operational efficiency, and equipment longevity—delivering measurable ROI for businesses.

Why Partner with Intensiv Filter Himenviro

Choosing Intensiv Filter Himenviro means investing in trusted engineering, industrial expertise, and long-term reliability. Our solutions are tailored to your facility’s unique needs, ensuring maximum efficiency, regulatory compliance, and worker safety. From installation to ongoing maintenance and spare part availability, we provide a complete lifecycle solution, making us the preferred partner for forward-thinking industrial operations.

Discover Our Range of Solutions:

Frequently Asked Questions

A dust collector works by capturing dust at its source, conveying it through a duct system, and collecting it using filtration, centrifugal separation, or electrostatic forces. Airborne particles are trapped in filters, cyclones, or wet scrubbers, ensuring clean air is released. This protects equipment, maintains regulatory compliance, and improves worker safety.

A baghouse dust collector uses fabric filters to remove dust particles from industrial air streams. Dust-laden air passes through filter bags, where particulates are trapped while clean air exits. They can achieve over 99% efficiency, support continuous operation, and are ideal for industries like cement, pharmaceuticals, and food manufacturing requiring fine dust removal.

Dust collector capacity depends on airflow volume, dust concentration, particle size, and air-to-cloth ratio. Proper sizing ensures efficient dust capture without settling in ducts or filter clogging. Engineers also consider temperature, humidity, and combustible dust factors to maintain safety, operational efficiency, and regulatory compliance across industries.

While dust collectors generate suction, they are designed for continuous industrial filtration, not portable cleaning. Using them as a vacuum is inefficient and may damage the system. Dust collectors are engineered to handle large airflow and high dust loads from production processes, whereas vacuums are for small-scale, intermittent dust removal.