Types of Industrial Temperature Controllers

Industrial temperature controllers come in different types, each suited for specific applications. The choice depends on the required accuracy, speed of response, and integration capabilities.

- On/Off Controllers: These operate on a simple principle—switching heating or cooling systems on when the temperature drops below the setpoint and turning them off when it exceeds the threshold. They are suitable for applications where minor fluctuations are acceptable.

- Proportional Controllers: Unlike on/off controllers, these adjust the heating or cooling output gradually to minimize overshooting and undershooting, leading to a more stable temperature control process.

- PID Controllers: Proportional-Integral-Derivative (PID) controllers are the most advanced type, continuously analyzing temperature trends and making predictive adjustments to maintain precision. They are widely used in industries requiring strict temperature stability, such as semiconductor manufacturing and pharmaceutical processing.

- Multi-Loop Controllers: These controllers regulate multiple temperature zones simultaneously, improving efficiency in complex industrial systems like large-scale manufacturing plants.

- Solid-State Relay (SSR) Controllers: Designed for high-power applications, SSR controllers offer smooth and rapid temperature control with minimal electrical noise, making them ideal for sensitive electronic processes.

Discover Our Range of Solutions:

Applications of Industrial Temperature Controllers

Industrial temperature controllers are essential across various industries, ensuring optimal conditions for production processes that depend on precise thermal management.

1. Manufacturing & Metal Processing

Temperature controllers regulate heating and cooling in metal forging, plastic molding, and welding operations, ensuring uniformity and preventing material defects.

2. Food & Beverage Industry

In food processing, precise temperature control is necessary for baking, pasteurization, refrigeration, and fermentation. Controllers help maintain hygiene and extend product shelf life.

3. Pharmaceutical & Biotechnology

Laboratories and pharmaceutical plants use temperature controllers to regulate incubators, sterilization equipment, and drug formulation processes to meet stringent industry regulations.

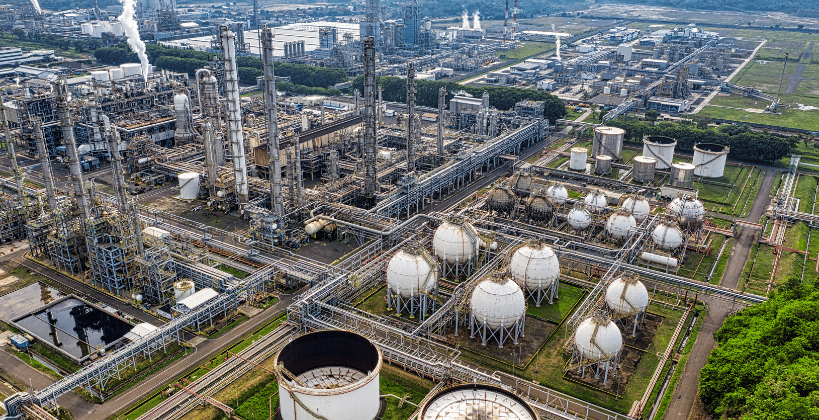

4. Chemical Processing

Exothermic and endothermic reactions in chemical plants require controlled temperature conditions to ensure safety, efficiency, and product consistency.

5. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in industrial and commercial spaces rely on temperature controllers to maintain stable indoor conditions.

6. Power Plants & Energy Sector

Boilers, turbines, and combustion systems in power plants depend on precise temperature regulation to optimize efficiency and prevent overheating or energy losses.

7. Semiconductor & Electronics Manufacturing

Microchip production and circuit testing require extremely stable temperature control to ensure precision and prevent defects in electronic components.

Key Benefits of Industrial Temperature Controllers

- Precision & Consistency: Prevents temperature fluctuations, improving product quality and reducing wastage.

- Energy Efficiency: Optimizes heating and cooling operations, leading to significant cost savings.

- Automation & Remote Monitoring: Advanced controllers integrate with industrial automation systems, allowing remote access and real-time adjustments.

- Equipment Longevity: Protects machinery from overheating or excessive cooling, reducing maintenance and repair costs.

- Regulatory Compliance: Helps industries adhere to safety and quality standards in sectors like pharmaceuticals and food processing.

- Workplace Safety: Prevents hazardous temperature deviations that could lead to accidents or equipment failures.

Connect with us Now

Choosing the Right Industrial Temperature Controller

Choosing the appropriate temperature controller hinges on several key factors. The level of accuracy required is paramount; high-precision industries often benefit from PID controllers, which offer finer control, while simpler applications may suffice with less sophisticated on/off controllers. Response time is another critical consideration, as industries requiring immediate temperature adjustments necessitate fast-acting controllers. Integration needs should also be evaluated, as controllers with digital interfaces and PLC compatibility facilitate seamless automation within existing systems.

Furthermore, the environmental conditions in which the controller will operate must be taken into account. Exposure to dust, humidity, or other harsh elements can impact the controller’s performance and longevity. Finally, ease of use and maintenance are important practical considerations. User-friendly interfaces and durable construction can simplify operation and reduce the frequency and complexity of maintenance efforts.

Why Choose Intensiv Filter Himenviro for Industrial Temperature Controllers?

Intensiv Filter Himenviro offers cutting-edge temperature control solutions tailored to diverse industrial applications. Our controllers provide superior accuracy, energy efficiency, and seamless integration with automation systems, ensuring optimal performance across industries.

What Sets Us Apart?

- Advanced PID Algorithms: Ensures precise and stable temperature control.

- Customizable Solutions: Tailored controllers for specific industrial needs.

- Energy-Saving Designs: Optimized for reduced power consumption.

- Reliable Performance: Built for durability in harsh industrial environments.

- Expert Support & Service: Comprehensive assistance for installation, integration, and maintenance.

Conclusion

Industrial temperature controllers play a vital role in maintaining optimal process conditions, ensuring quality control, and improving operational efficiency. Whether used in manufacturing, food processing, pharmaceuticals, or power plants, these controllers provide precise temperature regulation for consistent results.

With Intensiv Filter Himenviro’s advanced temperature control solutions, industries can achieve superior performance, reduced energy costs, and enhanced product quality. Investing in the right temperature controller is a crucial step toward automation, efficiency, and long-term operational success.