What is Metal Dust?

Metal dust consists of fine particles that come from metalworking processes. These processes include grinding, cutting, and welding. During these tasks, small bits of metal break off and become dust. Metal dust can be harmful because it can float in the air and be breathed in.

The characteristics of metal dust vary. The size of these particles is usually very small, often less than 10 micrometers. This means they can easily enter the lungs. The composition of metal dust depends on the type of metal being worked on. Common metals include steel, aluminum, and copper. Each type of metal dust has its own properties and effects in the workplace.

Metal dust can behave differently based on its size and composition. Smaller particles can stay airborne longer, making them more dangerous. They can settle on surfaces and create a risk of fire or explosion. It is important for workers to manage metal dust properly to keep the workplace safe.

Here is a table that shows different types of metal dust and their sources:

| Type of Metal Dust | Source |

| Steel Dust | Grinding steel |

| Aluminum Dust | Cutting aluminum |

| Copper Dust | Welding copper |

Intensiv Filter Himenviro offers solutions to help control metal dust in the workplace. They provide filters and systems to reduce the amount of dust in the air. This helps keep workers healthy and safe during metalworking processes.

Health Risks Associated with Metal Dust Exposure

Metal dust exposure can lead to serious health risks. The dangers come from inhaling tiny particles of metal. These particles can harm the body in various ways. The following points explain the health hazards linked to metal dust exposure.

- Respiratory diseases: Breathing in metal dust can cause conditions like asthma and other lung problems. Long-term exposure can lead to severe issues.

- Lung cancer: Studies show that workers who breathe in metal dust have a higher risk of developing lung cancer. The tiny particles can damage lung tissue over time.

- Chronic obstructive pulmonary disease (COPD): Metal dust can also lead to COPD. This disease makes it hard to breathe and can worsen over time.

- Neurological effects: Inhaling metal dust can affect the brain and nervous system. Some studies link metal exposure to memory and learning problems.

- Skin irritation: Touching metal dust can cause rashes and irritation on the skin. This can lead to discomfort and other skin issues.

Intensiv Filter Himenviro helps reduce metal dust exposure in workplaces. Using their filters can protect workers from these health hazards.

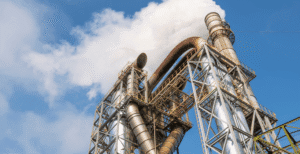

Metal Dusting: A Catastrophic Form of Corrosion

Metal dusting is a severe form of corrosion. It happens at high temperatures, between 300°C and 850°C, in carbon-rich environments. This type of corrosion can affect metals and alloys. When metal dusting occurs, it leads to the disintegration of these materials into fine particles.

In carbon-rich environments, metals react with carbon. The heat causes the metal to break down. This process creates small dust-like particles. These particles can weaken structures and cause failures in machinery or equipment.

Intensiv Filter Himenviro works to prevent metal dusting. They focus on reducing risks of corrosion in industrial settings. Their solutions help protect metals from breaking down. This protection is crucial for maintaining the strength and safety of various systems and structures.

A diagram can show how metal dusting happens. It will illustrate the process of metal reacting with carbon and breaking down into fine particles. Understanding this process is important for industries that deal with high temperatures and carbon-rich environments.

Prevention and Control Measures

To prevent and control metal dust risks, it is important to use specific strategies. These strategies help keep the workplace safe. Here are some ways to reduce metal dust risks:

- Engineering Controls: Use engineering controls to reduce dust at the source. This means using machines or tools that limit dust release during work.

- Ventilation Systems: Install ventilation systems. These systems improve airflow and help to remove dust from the air. Good ventilation keeps the air clean.

- Dust Collection Units: Use dust collection units. These units capture dust before it spreads into the workplace. They help keep the area cleaner.

- PPE: Provide personal protective equipment (PPE). This includes items like gloves and goggles that protect workers from dust.

- Respirators: Offer respirators to workers. These devices filter out harmful particles from the air. They are important for safety in dusty environments.

- Protective Clothing: Require workers to wear protective clothing. This clothing protects skin from dust exposure and makes cleaning easier.

- Workplace Practices: Follow good workplace practices. Train workers on how to handle materials safely to reduce dust creation.

- Cleaning: Keep the workplace clean. Regular cleaning helps remove dust that settles on surfaces. This reduces the chance of dust becoming airborne.

- Maintenance: Perform regular maintenance on machines. Well-maintained equipment produces less dust and operates safely.

- Monitoring: Monitor dust levels in the workplace. Regular checks help identify problems early and ensure that safety measures are effective.

Intensiv Filter Himenviro offers solutions that support these strategies. Their products help in managing and reducing metal dust risks effectively.

Regulatory Standards and Compliance

Regulations govern metal dust exposure to protect workers. OSHA standards set rules for workplace safety. NFPA guidelines also provide safety measures for handling hazardous materials. Following these regulations is crucial for compliance. Compliance helps ensure worker safety and avoids legal repercussions for companies.

Here is a table that compares key regulations and their requirements:

| Regulation | Key Requirements |

| OSHA Standards | Limits on dust exposure, regular monitoring |

| NFPA Guidelines | Proper ventilation, use of dust collection systems |

Intensiv Filter Himenviro offers solutions to help companies meet these regulations. They provide equipment that improves air quality and reduces metal dust exposure. By using their products, companies can enhance worker safety and stay compliant with regulations.

Innovations in Metal Dust Management

Innovations in metal dust management help keep workplaces safe and clean. New technology and materials make it easier to control metal dust. These innovations focus on better filtration and monitoring systems.

- Advanced Filtration Systems: Advanced filtration systems capture metal dust effectively. They use cutting-edge technology to filter out harmful particles. This keeps the air cleaner for everyone.

- High-Efficiency Filters: High-efficiency filters trap even the smallest dust particles. These filters are designed to last longer and work better. They help maintain a healthier environment.

- Automated Monitoring: Automated monitoring tracks dust levels in real time. This technology alerts workers when dust levels get too high. It helps maintain safety in the workplace.

- Sensors: Sensors detect metal dust quickly and accurately. They can be placed in various locations to monitor air quality. This helps to act fast if dust levels rise.

- IoT Devices: IoT devices connect different systems for better control. They share data about dust levels and filter health. This makes managing metal dust easier and more efficient.

- Sustainable Practices: Sustainable practices focus on reducing waste and promoting safety. Companies adopt these practices to minimize their environmental impact. They create a healthier workplace for all.

- Eco-Friendly Materials: Eco-friendly materials are used in dust management systems. These materials are safer for the environment. Using them supports a greener future.

Intensiv Filter Himenviro is a leader in these innovations. They offer advanced solutions to improve metal dust management. Their technology helps keep workplaces safe and clean.

Case Study: Intensiv Filter Himenviro’s Solutions

Intensiv Filter Himenviro provides effective filtration solutions to tackle metal dust challenges in various industries. In a recent case study, a manufacturing plant faced issues with metal dust. This dust posed health risks to workers and created environmental problems. The plant needed a reliable solution.

Intensiv Filter Himenviro assessed the plant’s needs. They designed a customized filtration system that targeted the specific types of metal dust present in the facility. The new system worked efficiently to capture and filter the dust from the air. This ensured a safer working environment for employees.

The filtration solutions from Intensiv Filter Himenviro also helped the plant meet environmental compliance standards. The system reduced emissions and improved air quality. This was important, as strict regulations exist to protect the environment and public health.

Sustainability was a key focus for the plant. By using Intensiv Filter Himenviro’s solutions, they reduced waste and energy consumption. The filtration system was effective and eco-friendly. This approach aligns with the plant’s commitment to sustainable practices.

In this case study, Intensiv Filter Himenviro demonstrated how tailored filtration solutions can address metal dust challenges, ensure environmental compliance, and promote sustainability in an industrial setting.

Conclusion

Understanding and managing metal dust is very important for health protection and safety. Metal dust can cause serious health problems if not handled correctly. It is crucial to take the right steps to reduce risks and keep people safe.

Readers should consult with experts like Intensiv Filter Himenviro. They offer customized solutions to meet specific needs. Their knowledge can help create a safer work environment.

If you want more information or need help, contact Intensiv Filter Himenviro for personalized consultations. They can guide you on the best ways to handle metal dust safely.