Traditional air filtration systems often struggle to effectively capture a wide range of particle sizes. Electrostatic precipitators (ESPs) excel at capturing fine particles but are less efficient with larger ones, while mechanical filters like bag filters efficiently capture coarse particles but struggle with finer ones. To overcome these limitations, hybrid electrostatic filters combine the strengths of both technologies. By integrating an electrostatic precipitator with a mechanical filtration stage, these innovative systems achieve superior air filtration efficiency by capturing a broader spectrum of particle sizes, resulting in cleaner air and improved overall system performance.

1. Electrostatic Precipitator (ESP) Section:

- Charging Mechanism: The ESP section uses a high voltage power supply to create a strong electric field between electrodes. This field ionizes the air molecules, creating free electrons and positively charged ions.

- Particle Charging: As the dust-laden air stream passes through the electric field, the particles collide with the ions and become charged themselves. The polarity of the charge (positive or negative) depends on the particle’s material properties.

- Collection Plates: The charged particles are attracted to collector plates with the opposite electrical charge. These plates are typically grounded for positive ions and connected to a high voltage source with opposite polarity for electrons.

- Particle Removal: Collected particles are periodically removed from the collector plates by rapping or vibration mechanisms. This ensures the plates remain clean and maintain efficient particle collection.

2. Mechanical Filtration Section:

- Filter Media: The mechanical filtration section typically uses a porous filter media, like a woven fabric bag. The specific media selection depends on factors like particle size, dust composition, and desired filtration efficiency.

- Depth Filtration: As the air stream passes through the filter media, dust particles are captured by various mechanisms like interception, impaction, and diffusion. Larger particles are primarily captured by interception, where their size prevents them from following the airflow through the media’s pores.

- Cake Formation: Over time, a layer of captured particles, called a “cake,” builds up on the filter media’s surface. This cake can actually improve the filtration efficiency for even finer particles as the air stream must flow through the accumulated dust layer. However, excessive cake buildup can increase pressure drop across the filter, requiring maintenance or filter replacement.

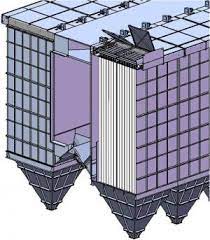

3. Filter Configuration:

- ESP before Mechanical Filter (Pre-charging): This is the most common configuration. Pre-charging particles in the ESP significantly enhances their capture by the mechanical filter. This reduces the amount of dust loading on the filter media, extending its lifespan and reducing pressure drop across the entire filtration system.

- ESP after Mechanical Filter (Final Capture): In this configuration, the mechanical filter captures the bulk of the particles, and the downstream ESP acts as a polishing stage to capture any remaining fine particles that escape the mechanical filter. This configuration might be suitable for applications with a high concentration of very fine particles.

Additional Considerations:

- Power Consumption: The ESP section requires a high voltage power supply, which can be a significant factor in overall system operating costs. Optimizing the design and operation of the ESP to achieve the desired efficiency while minimizing energy consumption is crucial.

- Cleaning Mechanisms: Both the ESP collector plates and the mechanical filter media require periodic cleaning to maintain efficient operation. The specific cleaning mechanisms employed depend on the filter design and application.

- Maintenance Needs: Hybrid electrostatic filters generally require more maintenance than traditional bag filters due to the added complexity of the ESP section. Regular maintenance ensures optimal performance and extends the lifespan of the filter media and other components.

By understanding these technical aspects, you can gain a deeper appreciation for how hybrid electrostatic filters achieve superior air filtration efficiency for a wide range of particle sizes.

Benefits of Hybrid Electrostatic Filters:

While you’ve covered the core benefits of hybrid electrostatic filters, here’s how we can expand on them:

Enhanced Efficiency:

- Broader Spectrum Capture: By combining ESP technology with mechanical filtration, hybrid filters capture a wider range of particles than either technology alone. This is crucial for applications with mixed dust streams containing both coarse and fine particles.

- Submicron Particle Removal: Fine and submicron particles (less than 1 micron in diameter) are particularly hazardous to human health and can easily bypass traditional filtration systems. Hybrid filters effectively capture these fine particles due to the pre-charging action of the ESP, significantly improving air quality.

- Reduced Emissions Compliance: Many industries face stringent regulations regarding air emissions. Hybrid filters can help companies meet these regulations by ensuring efficient capture of pollutants, minimizing the amount released into the atmosphere.

Reduced Pressure Drop:

Lower pressure drop across a filter translates to substantial energy savings. With reduced resistance, the fan system requires less energy to move air through the filter, resulting in lower operating costs over time. Additionally, a lower pressure drop can often enable increased air flow rates without the need for additional fans, benefiting systems handling high air volumes. This reduced pressure also extends filter life by minimizing stress on the filter media, delaying replacement and reducing maintenance requirements.

Extended Filter Life with Hybrid Electrostatic Filters

Hybrid filters, combining electrostatic precipitation (ESP) and mechanical filtration, offer significant advantages in terms of filter life and overall system performance. The ESP section pre-charges dust particles, significantly reducing the load on the subsequent mechanical filter. This slower rate of cake formation on the filter media extends operation times between cleaning or replacement cycles, leading to lower maintenance costs and reduced waste generation. Hybrid filters are versatile, adaptable to various applications through careful selection of ESP configuration (pre or post-filter) and filter media. Constructed with robust materials, they withstand harsh industrial environments. Effective hybrid filter operation hinges on optimal electrode design for efficient particle charging (wire-plate or rod electrodes) and appropriate filter media selection based on specific application needs. A high-voltage power supply is essential for the ESP’s operation.

Conclusion of Hybrid Electrostatic Filters

Hybrid electrostatic filters represent a significant advancement in air filtration technology, offering superior performance compared to traditional methods. By combining the strengths of electrostatic precipitation and mechanical filtration, these systems excel at capturing a wide range of particle sizes, including those that are particularly challenging to remove. The result is cleaner air, reduced emissions, and improved overall system efficiency. With lower energy consumption, extended filter life, and adaptability to various applications, hybrid electrostatic filters offer a compelling solution for industries seeking advanced air filtration solutions. As technology continues to evolve, we can expect further refinements in hybrid filter design and performance, leading to even greater benefits for users.