Introduction to Electrostatic Precipitator Parts

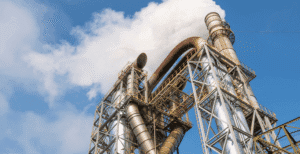

Electrostatic precipitators (ESPs) are widely used in industries for controlling air pollution by removing particulate matter from flue gases. These devices function by applying an electrical charge to airborne particles, attracting them to collector plates, and ensuring clean air emissions. The efficiency and reliability of an ESP depend significantly on its components. Each part plays a crucial role in determining the overall performance and longevity of the system. Understanding these parts is essential for maintaining and upgrading industrial dust collection systems.

At Intensiv-Filter Himenviro, we specialize in supplying high-quality electrostatic precipitator parts, ensuring optimal operation, durability, and efficiency for various industrial applications. Our expertise allows industries to maintain compliance with environmental regulations while reducing maintenance costs.

Key Components of an Electrostatic Precipitator

An ESP comprises several essential parts, each designed to contribute to the efficient removal of particulate matter. These include electrodes, discharge systems, insulators, hoppers, and rapping mechanisms. Understanding these components and their functions helps industries optimize their ESPs and ensure long-term efficiency.

Electrodes: The Core of ESP Functionality

Electrodes are critical in generating the electric field required for particle collection. They can be categorized into discharge electrodes and collection electrodes. The discharge electrodes ionize dust particles, while collection electrodes attract and trap them. Maintaining these components in proper working condition is essential for achieving high collection efficiency.

Discharge System and Power Supply

The high-voltage power supply system plays a pivotal role in ESP performance. It provides the necessary electric charge to ionize particles, making them adhere to collection plates. Any faults in the power supply system can lead to reduced efficiency, requiring immediate inspection and replacement when needed.

Insulators: Ensuring Reliable Operation

Insulators prevent electrical leakage and ensure proper functioning of the ESP. They must withstand high temperatures and resist contamination. High-quality insulators contribute significantly to the overall reliability of the system.

Hoppers for Collected Dust Storage

Once the dust is removed from the air stream, it collects in hoppers located at the base of the ESP. Regular maintenance of these hoppers is crucial to prevent blockages and ensure smooth operation.

Rapping Mechanisms and Cleaning Systems

The rapping mechanism is responsible for dislodging dust from the collection plates. It uses mechanical vibrations or electromagnetic impulses to shake off accumulated particles. A well-maintained rapping system ensures consistent dust removal and prevents re-entrainment.

Discover Our Range of Solutions:

Common Replacement Parts for Electrostatic Precipitators

To ensure the continuous and efficient operation of Electrostatic Precipitators (ESPs), industries frequently replace critical components that are subject to wear and tear over time. Regular maintenance and timely replacement of these parts help maintain optimal performance, minimize downtime, and ensure compliance with environmental regulations. Some of the most commonly replaced ESP components include:

- Discharge Electrodes: These essential components are responsible for ionizing and charging dust particles, allowing them to be collected on the plates. Over time, they may wear out, become misaligned, or lose their effectiveness due to prolonged exposure to high-voltage electrical fields. Replacing worn-out discharge electrodes is crucial for maintaining the efficiency of the ESP.

- Collection Plates: These plates serve as the primary surfaces where charged particles accumulate before being removed. If they become damaged, corroded, or coated with excessive residue, their ability to capture dust efficiently diminishes. Replacing worn collection plates helps ensure optimal particle collection and sustained performance.

- Transformer-Rectifier (TR) Units: TR units are responsible for providing the high-voltage power supply required for ESP operation. Any faults or malfunctions in these units can lead to reduced efficiency or complete system failure. Regular inspection and prompt replacement of faulty TR units help maintain a stable and reliable power supply.

- Rappers and Vibrators: These components play a crucial role in dislodging accumulated dust from collection plates and electrodes, ensuring effective particle removal. If rappers and vibrators become worn out or fail to function properly, dust buildup can reduce the overall efficiency of the ESP. Periodic replacement of these parts helps maintain consistent operation.

- Insulator Heaters: Insulators prevent electrical leakage by maintaining proper insulation between high-voltage components. However, moisture accumulation can compromise their effectiveness. Insulator heaters help prevent condensation and maintain system integrity, making their timely replacement essential for uninterrupted operation.

How Intensiv-Filter Himenviro Supports Your ESP Needs

At Intensiv-Filter Himenviro, we offer a comprehensive range of electrostatic precipitator (ESP) parts engineered for durability, efficiency, and long-term performance. Our high-quality components help industries minimize downtime, maintain compliance with stringent environmental regulations, and enhance the overall effectiveness of their ESP systems. With our expertise and commitment to excellence, we provide reliable solutions tailored to meet the unique demands of various industrial applications.

Why Choose Our ESP Parts?

- High-Quality Materials: We utilize robust, durable, and corrosion-resistant materials to extend the lifespan of ESP components, ensuring consistent performance even in harsh operating conditions.

- Customization Options: Our parts are designed for compatibility with a wide range of ESP models, allowing seamless integration and optimal functionality across different industrial setups.

- Expert Guidance: Our experienced team provides comprehensive technical support, assisting industries in selecting the right components for their specific operational requirements, ensuring maximum efficiency and reliability.

- Global Supply Chain: With an efficient and well-established distribution network, we ensure timely delivery of ESP parts to industries worldwide, reducing operational disruptions and helping businesses maintain uninterrupted productivity.

At Intensiv-Filter Himenviro, we are committed to delivering top-tier ESP components that enhance filtration efficiency, optimize system performance, and support sustainable industrial operations.

Connect with us Now

Maintenance Tips for Electrostatic Precipitator Parts

To maximize the lifespan of ESP components and maintain peak efficiency, regular maintenance is crucial. Proper upkeep helps prevent unexpected failures, reduces downtime, and ensures compliance with environmental standards.

- Routine Inspections: Conduct periodic checks to detect worn-out or damaged components before they compromise system performance.

- Cleaning Electrodes and Insulators: Regularly remove dust and contaminants to maintain effective particle collection and electrical insulation.

- Monitoring Power Supply Systems: Ensure transformer-rectifier units deliver stable voltage and current for consistent ESP operation.

- Lubricating Moving Parts: Apply proper lubrication to rapping mechanisms and other moving components to prevent mechanical wear and failures.

- Timely Replacement of Parts: Proactively replace aging or faulty components to enhance efficiency and minimize operational disruptions.

By following these maintenance practices, industries can optimize ESP performance, extend equipment life, and ensure uninterrupted air filtration efficiency.

Conclusion

Electrostatic precipitators (ESPs) are essential for controlling industrial air pollution by efficiently capturing and removing airborne particles, dust, and contaminants. The overall effectiveness of these systems is directly influenced by the quality, durability, and maintenance of their individual components. Ensuring that all ESP parts function optimally is key to achieving high filtration efficiency, minimizing emissions, and complying with strict environmental regulations.

At Intensiv-Filter Himenviro, we provide a comprehensive range of premium-quality ESP components designed for superior performance and longevity. Our parts are manufactured using high-grade, corrosion-resistant materials to withstand the demanding conditions of industrial applications. By investing in our reliable and durable ESP components, industries can reduce system downtime, enhance pollutant removal efficiency, and maintain compliance with environmental safety standards.

Regular maintenance and timely replacement of essential ESP parts—such as discharge electrodes, collection plates, and transformer-rectifier units—are crucial for sustaining optimal system performance. Proper upkeep helps prevent operational disruptions, extends equipment lifespan, and ensures consistent air purification efficiency.

By choosing Intensiv-Filter Himenviro for high-quality ESP components and adhering to effective maintenance practices, industries can maximize their air filtration system’s effectiveness, achieve long-term operational success, and contribute to a cleaner and healthier environment.