Centrifugal blowers are a crucial component in various industrial processes, providing efficient air movement and pressure generation. These blowers operate by increasing the speed of air or gas using a rotating impeller and then converting that kinetic energy into pressure. This mechanism makes them suitable for applications requiring steady and controlled airflow.

How Centrifugal Blowers Work

A centrifugal blower functions by utilizing an impeller, which is a rotating disk with blades that accelerate the air outward. As the air moves radially through the impeller, it gains kinetic energy, which is then converted into pressure when directed into a diffuser or volute casing. Unlike axial fans, which push air parallel to the axis, centrifugal blowers expel air at an angle, increasing pressure and enabling applications where high static pressure is required.

The working principle of centrifugal blowers ensures reliable and efficient air movement, making them widely applicable across industries such as power plants, manufacturing, HVAC systems, and pollution control. Their ability to operate in high-pressure conditions while maintaining stable airflow makes them superior to traditional fans in many applications.

Discover Our Range of Solutions:

Types of Centrifugal Blowers

Centrifugal blowers come in different types based on their impeller design, airflow direction, and pressure output. Some of the most common types include:

- Forward-Curved Blowers – These have small, forward-tilting blades that generate high airflow but at lower pressure. They are commonly used in HVAC applications.

- Backward-Curved Blowers – These feature blades that curve backward, offering high efficiency and low noise, making them ideal for industrial ventilation and combustion air supply.

- Radial Blowers – Designed with straight radial blades, these blowers provide high-pressure output and are often used in dust collection and material handling applications.

- Airfoil Blowers – Known for their aerodynamic blade design, airfoil blowers offer the highest efficiency with minimal noise and energy consumption.

- Multistage Blowers – These incorporate multiple impellers to achieve extremely high pressures, making them suitable for applications such as wastewater treatment and pneumatic conveying.

Selecting the right type of filters depends on the specific needs of an industry, including airflow requirements, pressure levels, and operational efficiency.

Key Applications of Centrifugal Blowers

Centrifugal blowers are indispensable across various sectors due to their versatility, efficiency, and reliability. Here are some primary applications:

1. HVAC and Air Handling

Centrifugal blowers are integral to heating, ventilation, and air conditioning (HVAC) systems. They help regulate airflow, control humidity levels, and maintain indoor air quality in residential, commercial, and industrial buildings.

2. Industrial Ventilation

Factories, warehouses, and production facilities use centrifugal blowers to remove fumes, dust, and contaminants, ensuring a safer working environment. These blowers help comply with industrial air quality regulations.

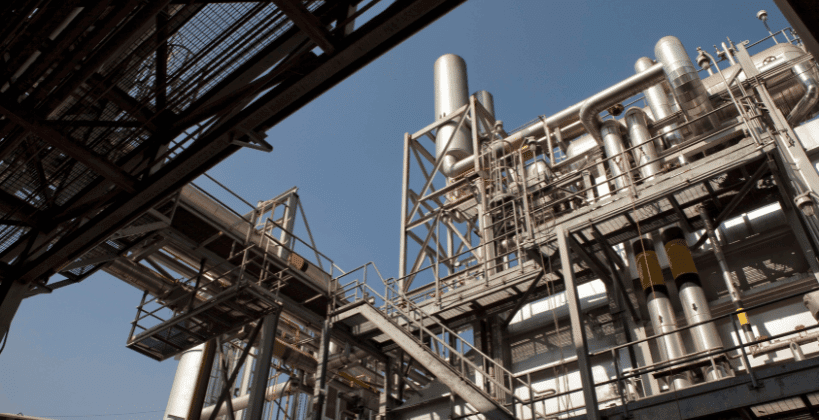

3. Power Plants and Boilers

Centrifugal blowers are critical in power plants, supplying combustion air to boilers and ensuring efficient fuel burning. They also assist in cooling turbine components and exhaust gas management.

4. Pollution Control Systems

Industries involved in pollution control rely on centrifugal blowers for processes like flue gas desulfurization, dust collection, and scrubber systems. These blowers contribute to reducing harmful emissions and ensuring compliance with environmental regulations.

5. Material Handling and Pneumatic Conveying

In industries such as cement, mining, and food processing, centrifugal blowers assist in pneumatic conveying systems, moving materials efficiently through pipelines. They are also used in grain drying and seed processing operations.

6. Wastewater Treatment

Aeration is a crucial process in wastewater treatment plants, and centrifugal blowers provide the necessary air supply to activate sludge and promote bacterial growth, which helps in breaking down organic waste.

7. Drying and Cooling Systems

Centrifugal blowers are used in drying processes, including paper manufacturing, textile production, and chemical processing. They provide consistent airflow to remove moisture and maintain product quality.

Connect with us Now

Advantages of Centrifugal Blowers

- High Efficiency: Centrifugal blowers operate with minimal energy consumption while maintaining high airflow and pressure output.

- Versatility: These blowers can handle a wide range of industrial applications, from ventilation to material transport and pollution control.

- Durability: Made with robust materials, centrifugal blowers are designed to withstand extreme operating conditions, including high temperatures and corrosive environments.

- Stable Airflow: Unlike axial fans, centrifugal blowers provide a more stable and uniform airflow, making them ideal for sensitive industrial processes.

- Low Maintenance: With fewer moving parts and durable construction, centrifugal blowers require less frequent maintenance, reducing operational costs.

- Customization Options: Available in various designs, sizes, and capacities, these blowers can be tailored to meet the specific needs of different industries.

Choosing the Right Centrifugal Blower

When selecting a centrifugal blower for an industrial application, several factors must be considered:

- Airflow Requirements: Determine the required cubic feet per minute (CFM) of airflow to ensure proper performance.

- Static Pressure Needs: The blower must be capable of generating sufficient pressure to overcome system resistance.

- Efficiency and Power Consumption: Choosing an energy-efficient model can reduce operational costs and environmental impact.

- Material and Construction: Depending on the application, corrosion-resistant materials like stainless steel may be necessary.

- Noise Levels: Industries with strict noise regulations should opt for blowers with sound-dampening features.

- Maintenance and Longevity: Consider models that require minimal maintenance while offering maximum durability.

Why Choose Intensiv Filter Himenviro for Centrifugal Blowers?

Intensiv Filter Himenviro is a leading provider of high-quality centrifugal blowers designed to meet the most demanding industrial applications. Our blowers are engineered with precision, offering superior performance, efficiency, and reliability. Here’s why industries trust us:

- Innovative Design: We employ cutting-edge technology to optimize airflow dynamics and efficiency.

- Customization: Our blowers are tailored to match the specific needs of different industries, from HVAC to power generation.

- Energy Efficiency: Designed to minimize energy consumption, our blowers help industries reduce operational costs.

- Robust Construction: Made with high-quality materials, our blowers ensure longevity and consistent performance.

- Expert Support: Our team of engineers provides technical assistance to help clients choose the best solutions for their applications.

Conclusion

Centrifugal blowers play a vital role in industrial air movement, offering efficient airflow and pressure generation for various applications. From HVAC and power plants to pollution control and material handling, their versatility and reliability make them indispensable across industries. Intensiv Filter Himenviro provides high-quality centrifugal blowers designed for optimal performance, durability, and energy efficiency. With our advanced engineering and commitment to excellence, we offer solutions that enhance industrial productivity while ensuring environmental compliance.