Air pollution is a growing concern in industrial, commercial, and residential settings. With increasing environmental challenges and stringent air quality regulations, air filtration technology plays a vital role in removing contaminants and improving air quality. Whether in industrial manufacturing, healthcare, HVAC systems, or environmental protection, effective air filtration ensures a safer and healthier atmosphere.

Modern air filtration technologies have evolved to combat airborne pollutants, dust, allergens, bacteria, and chemical fumes. From high-efficiency particulate air (HEPA) filters to electrostatic precipitators and activated carbon filters, industries rely on these innovations to maintain compliance and protect employees, equipment, and the environment.

How Air Filtration Technology Works

Air filtration systems are designed to capture and remove airborne contaminants using various mechanisms, including mechanical, electrostatic, and chemical filtration. These systems operate by pulling in contaminated air, passing it through filtration media, and releasing purified air back into the environment. Depending on the application, filtration technology can be used for removing dust particles, volatile organic compounds (VOCs), smoke, bacteria, and gases.

The effectiveness of an air filtration system depends on factors such as filter type, airflow rate, particle size, and filtration efficiency. Advanced air purification technologies also integrate sensors, automated controls, and energy-efficient designs to optimize performance and reduce maintenance costs.

Types of Air Filtration Technology

Various air filtration technologies cater to different applications, offering unique advantages based on filtration efficiency and operational requirements.

- HEPA Filters: High-Efficiency Particulate Air (HEPA) filters capture 99.97% of airborne particles as small as 0.3 microns. They are widely used in hospitals, pharmaceutical industries, and cleanrooms.

- Activated Carbon Filters: These filters use porous carbon to absorb gases, odors, and chemical fumes, making them ideal for industrial air purification and indoor air quality management.

- Electrostatic Precipitators: This technology uses an electric charge to attract and trap fine particles, commonly used in power plants and industrial exhaust systems.

- UV-C Light Air Purifiers: Ultraviolet germicidal irradiation (UVGI) systems neutralize airborne pathogens, bacteria, and viruses in healthcare and laboratory environments.

- Ionic Air Purifiers: These devices release charged ions that bond with pollutants, making them heavier and easier to filter.

- Cyclone Separators: Used in industrial applications, these filters rely on centrifugal force to separate large particles from the air before they reach finer filtration stages.

- Baghouse Filters: Large-scale filtration systems used in cement plants, metal industries, and manufacturing processes to control heavy dust emissions.

Applications of Air Filtration Technology

Air filtration technology is essential in various industries, ensuring regulatory compliance, workplace safety, and environmental protection.

1. Industrial Manufacturing

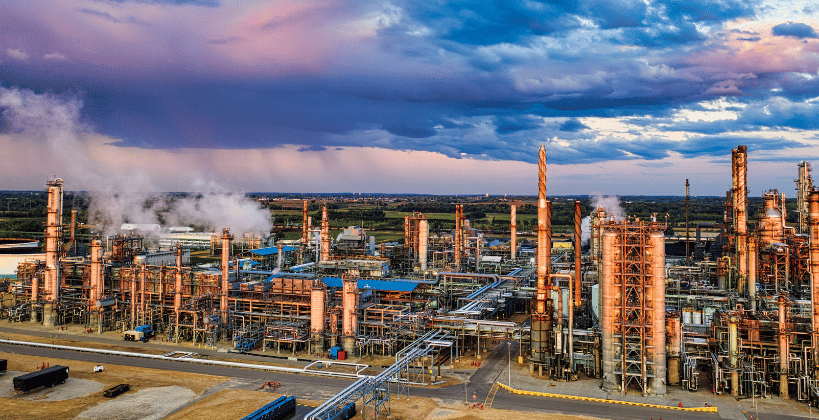

Factories and production plants generate significant airborne pollutants, including dust, fumes, and chemicals. Industrial air filtration systems help maintain clean air, protecting workers and preventing equipment damage.

2. Healthcare & Pharmaceuticals

Hospitals, laboratories, and pharmaceutical production facilities rely on HEPA and UV air filtration systems to eliminate bacteria, viruses, and airborne contaminants, ensuring sterile environments.

3. HVAC & Indoor Air Quality

Commercial buildings, offices, and residential spaces use air filtration technology in HVAC systems to remove allergens, mold spores, and pollutants, improving indoor air quality.

4. Power Plants & Energy Sector

Electrostatic precipitators and baghouse filters control emissions in coal-fired plants, reducing particulate pollution and meeting environmental standards.

5. Food Processing & Agriculture

Airborne contaminants in food production can compromise safety and hygiene. Filtration systems control dust, bacteria, and odors, ensuring regulatory compliance.

6. Aerospace & Automotive Industry

Manufacturing facilities producing vehicles and aircraft use air filtration to control dust from metal cutting, painting, and finishing processes.

7. Data Centers & Electronics

Microelectronics and semiconductor production require ultra-clean environments, where high-efficiency air filtration prevents contamination that could affect sensitive equipment.

Discover Our Range of Solutions:

Benefits of Advanced Air Filtration Technology

- Improved Air Quality: Efficient removal of airborne pollutants, dust, and harmful particles.

- Health & Safety Compliance: Reduces exposure to allergens, bacteria, and toxic fumes, creating safer environments.

- Energy Efficiency: Modern air filtration systems optimize airflow, reducing energy consumption and operational costs.

- Equipment Protection: Minimizes dust accumulation in industrial machines, preventing overheating and mechanical failures.

- Regulatory Compliance: Helps industries meet environmental and workplace safety regulations, avoiding fines and legal issues.

- Sustainability: Advanced air filters reduce emissions, contributing to environmental protection and sustainability goals.

Choosing the Right Air Filtration Technology

Selecting the appropriate air filtration system depends on several factors, including:

- Type of Pollutants: Identifying airborne contaminants helps determine the most effective filtration technology.

- Efficiency Requirements: Industries requiring high-purity air should opt for HEPA or advanced electrostatic filters.

- Airflow Capacity: The system should handle the required air volume while maintaining optimal filtration performance.

- Maintenance & Lifespan: Long-lasting, low-maintenance filters reduce operational costs and downtime.

- Integration with Existing Systems: Compatibility with HVAC, ventilation, and process control systems ensures seamless operation.

Why Choose Intensiv Filter Himenviro for Air Filtration Solutions?

Intensiv Filter Himenviro is a leader in air filtration technology, providing customized solutions for industrial, commercial, and environmental applications. Our filtration systems are designed for maximum efficiency, regulatory compliance, and sustainability.

What Sets Us Apart?

- Cutting-Edge Filtration Technology: Our advanced HEPA, activated carbon, and electrostatic filters ensure superior air purification.

- Customized Solutions: We design air filtration systems tailored to specific industry requirements.

- Energy-Efficient Designs: Optimized for reduced power consumption while maintaining high performance.

- Durability & Reliability: Built with high-quality materials for long-term usage and minimal maintenance.

- Expert Consultation & Support: Our team provides end-to-end solutions, from installation to ongoing maintenance.

Conclusion

Air filtration technology plays a vital role in maintaining clean, safe, and efficient industrial and commercial environments. From removing dust and pollutants in factories to ensuring sterile air in healthcare facilities, advanced filtration systems are indispensable for modern industries.

With Intensiv Filter Himenviro’s innovative air filtration solutions, businesses can achieve better air quality, enhanced worker safety, and compliance with stringent environmental regulations. Investing in high-quality air filtration technology is not just a necessity but a commitment to health, sustainability, and operational excellence.