Kontor

HUVUDKONTORET

Tyskland

- Intensivfilter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Tyskland/Tyskland - +49 20534200990

REGIONALKONTOR

Storbritannien

- Intensivfilter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Storbritannien - +44 1922 628893

REGIONALKONTOR

Förenade Arabemiraten

- Intensivfilter Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REGIONALKONTOR

Indien

- Intensivfilter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Indien - +91-120-4642-500

REGIONALKONTOR

Indien

- Intensivfilter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Indien - +91-120-4642-500

REGIONALKONTOR

Indien

- Intensivfilter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Indien - +91-120-4642-500

Luft- och dammfiltreringslösningar för kemisk industri

Kemiindustrin involverar processer som ofta genererar farliga luftburna partiklar, ångor och rök som kan påverka arbetstagarnas säkerhet, produktkvalitet och miljömässig hållbarhet. Våra luft- och dammfiltreringslösningar är specifikt utformade för att hantera de unika utmaningarna inom kemisk tillverkning, där de fångar upp partiklar, gaser och kemiska rök vid kritiska punkter under hela produktionen. Från råvaruhantering till förpackning är våra system byggda för att säkerställa överensstämmelse med strikta myndighetsstandarder, skydda arbetstagare från exponering och skydda miljön samtidigt som driftseffektiviteten bibehålls.

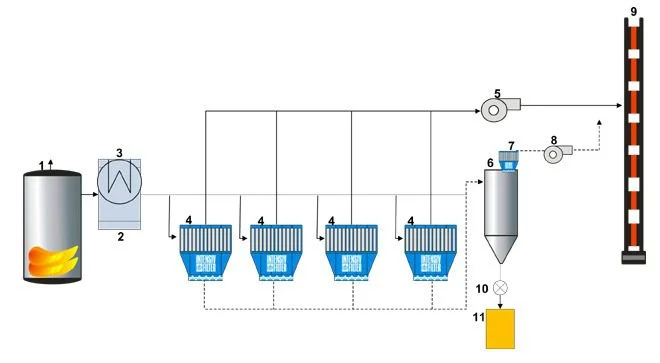

Damfiltreringsprocess inom kemisk industri

Klimatförändringar och klimatskydd spelar en allt viktigare roll. Därför har de olika affärsenheterna inom den kemiska industrin förbundit sig att minska utsläppen, till exempel (”Responsible Care”). Baserat på exemplet med en restförbränningsanläggning i ett kemiföretag, avlägsnas damm med svåra rengöringsegenskaper från systemet. En filtrerande avskiljare används för borttagning av rökgasdamm.

Filter för restförbränningsugn

Filter för restförbränningsugn

Filter för restförbränningsugn

Filter för restförbränningsugn

Silofilter

- 1. Förbränningsanläggning

- 2. Ångpanna

- 3. Värmeväxlare

- 4. Filter för restförbränningsugn

- 5. Inducerad dragfläkt

- 6. Silo

- 7. Silofilter

- 8. Transportörsfläkt

- 9. Skorsten

- 10. Dammutsläpp

- 11. Avfallshantering

Obligatoriska specifikationer

Typiska designdata | Restförbränningsugnar |

|---|---|

Gasvolym | 50 – 150 000 |

Gastemperatur | 180 – 240 |

Typ av damm | Flygaska |

Innehåll av rågasdamm | 5 |

Resterande dammhalt | < 5 |

Rengöring | online filter |

Filtermedium | Glas / Polytetrafluoreten |

Sorbent | Kalciumhydroxid |

Användningsområden för dammkontroll i den kemiska industrin

Fångar upp luftburet damm och ångor som genereras under kemiska reaktioner, blandning och andra tillverkningsprocesser, vilket minskar exponeringen för skadliga kemikalier.

Kontrollerar damm under lagring, hantering och transport av råa kemikalier, vilket förhindrar luftburen kontaminering och säkerställer säkerheten.

Minskar exponeringen för flyktiga organiska föreningar (VOC) och andra farliga partiklar under kemiska reaktions- och blandningssteg, vilket säkerställer en säkrare produktionsmiljö.

Minimerar damm- och rökutsläpp under förpacknings- och distributionsprocesser för att säkerställa att färdiga produkter förblir fria från föroreningar.

Regelverk för dammkontroll |

|---|

Efterlevnad av luftkvalitetsstandarder |

Efterlevnad av arbetstagarnas hälsa och säkerhet |

Förebyggande av brand- och explosionsrisker |

Efterlevnad av miljöskydd |

Realtidsutsläppsövervakning |

Värme- och kemikalieresistens |

Minskade driftstopp och underhållskostnader |

Produktintegritet och konsekvens |

Lägre driftskostnader |

Utmaningar med dammkontroll |

|---|

Hantering av farligt damm och ångor |

Hantering av andningsrisker för arbetstagare |

Uppfyller strikta miljöföreskrifter |

Förbrännings- och explosionsrisker |

Bibehålla produktkvalitet och renhet |

Frätande material och extrema temperaturer |

Utrustningsslitage |

Hög damm- och rökgenerering |

Driftstopp på grund av systemunderhåll |

Viktiga överväganden för effektiv dammkontroll |

|---|

Effektiv damm- och rökavskiljning |

Kemisk och värmebeständighet |

Optimerad luftflödes- och tryckhantering |

Avancerade filtreringsmaterial |

Rutinmässigt underhåll och inspektioner |

Överensstämmelse med regelverk |

Anpassade filtreringslösningar |

Riskreducering för farliga kemikalier |

Flexibla systemkonfigurationer |

Kontakta oss för expertkonsultation

Utforska våra andra tjänster!

Vanliga frågor

Filtreringssystem som används i kemisk bearbetning inkluderar filter i filterhus för uppsamling av torrt damm, elektrostatiska filter för hantering av fina partiklar, våtskrubber för kontroll av sura gaser och ångor, och patronfilter för mindre volymer eller precisionskontroll av luftkvaliteten. I processer som involverar höga temperaturer eller aggressiva kemikalier används även hetgasfiltreringssystem med sintrade metallmedier. Varje lösning väljs utifrån utsläppens natur, processförhållandena och miljökrav.

Filtreringssystem inom kemisk tillverkning förbättrar luftkvaliteten genom att effektivt fånga upp och avlägsna partiklar och föroreningar som genereras under bearbetningen. Genom att minska utsläpp hjälper dessa system anläggningar att följa miljöföreskrifter och standarder, vilket minimerar deras miljöpåverkan och främjar en säkrare arbetsplats.

Respiratorer för gaser (ESP) erbjuder hög effektivitet vid borttagning av fina partiklar och uppnår en effektivitet på upp till 99%, vilket är särskilt fördelaktigt vid kemisk produktion där rökgasutsläpp ofta innehåller fina dammpartiklar. De kan hantera stora gasvolymer och fungera effektivt vid höga temperaturer. Dessutom har ESP:er relativt låga tryckfall, vilket resulterar i lägre energiförbrukning under drift.