Pisarne

SEDEŽ

Nemčija

- Intenzivni filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Nemčija/Nemčija - +49 20534200990

OBMOČNI URAD

Velika Britanija

- Intenzivni filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Velika Britanija - +44 1922 628893

OBMOČNI URAD

Združeni arabski emirati

- Intenzivni filter Himenviro Technologies FZE – LLC

Poslovni center, Sharjah Publishing City Free Zone, Sharjah, ZAE - +971-556074697

OBMOČNI URAD

Indija

- Intensiv-Filter Himenviro Private Limited

D-247/11, sektor-63, Noida - 201301, Uttar Pradesh, Indija - +91-120-4642-500

OBMOČNI URAD

Indija

- Intensiv-Filter Himenviro Private Limited

D-247/11, sektor-63, Noida - 201301, Uttar Pradesh, Indija - +91-120-4642-500

OBMOČNI URAD

Indija

- Intensiv-Filter Himenviro Private Limited

D-247/11, sektor-63, Noida - 201301, Uttar Pradesh, Indija - +91-120-4642-500

Rešitve za filtracijo zraka in prahu v kemični industriji

Kemična industrija vključuje procese, ki pogosto ustvarjajo nevarne delce, hlape in izpare v zraku, ki lahko vplivajo na varnost delavcev, kakovost izdelkov in okoljsko trajnost. Naše rešitve za filtracijo zraka in prahu so posebej zasnovane za reševanje edinstvenih izzivov kemične proizvodnje, saj zajemajo trdne delce, pline in kemične hlape na kritičnih točkah med proizvodnjo. Od ravnanja s surovinami do pakiranja so naši sistemi zasnovani tako, da zagotavljajo skladnost s strogimi regulativnimi standardi, ščitijo delavce pred izpostavljenostjo in varujejo okolje, hkrati pa ohranjajo operativno učinkovitost.

Postopek filtracije prahu v kemični industriji

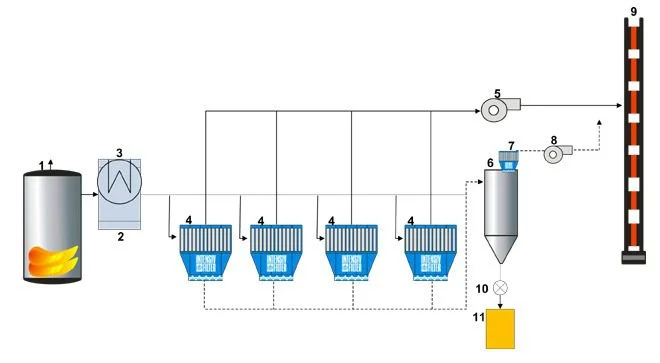

Podnebne spremembe in varstvo podnebja igrajo vse pomembnejšo vlogo. Zato so se različne poslovne enote kemične industrije zavezale na primer zmanjšanju emisij (»odgovorna skrb«). Na podlagi primera kurilne naprave za ostanke v kemičnem podjetju se iz sistema odstrani prah, ki ima težave s čiščenjem. Za odstranjevanje prahu iz odpadnih plinov se uporablja filtrirni zbiralnik.

Filter za peč za zgorevanje ostankov

Filter za peč za zgorevanje ostankov

Filter za peč za zgorevanje ostankov

Filter za peč za zgorevanje ostankov

Silosni filter

- 1. Kurilna naprava

- 2. Parni kotel

- 3. Toplotni izmenjevalnik

- 4. Filter za peč za zgorevanje ostankov

- 5. Induciran ventilator

- 6. Silos

- 7. Silosni filter

- 8. Ventilator transportnega traku

- 9. Dimnik

- 10. Odvajanje prahu

- 11. Odstranjevanje

Zahtevane specifikacije

Tipični konstrukcijski podatki | Peči za zgorevanje ostankov |

|---|---|

Prostornina plina | 50 – 150.000 |

Temperatura plina | 180 – 240 |

Vrsta prahu | leteči pepel |

Vsebnost prahu v surovem plinu | 5 |

Vsebnost preostalega prahu | < 5 |

Čiščenje | spletni filter |

Filtrirni medij | Steklo / politetrafluoretilen |

Sorbent | Kalcijev hidroksid |

Uporaba v kemični industriji za nadzor prahu

Zajame prah in hlape v zraku, ki nastanejo med kemičnimi reakcijami, mešanjem in drugimi proizvodnimi procesi, s čimer zmanjša izpostavljenost škodljivim kemikalijam.

Nadzoruje prah med skladiščenjem, ravnanjem in prenosom surovih kemikalij, preprečuje kontaminacijo zraka in zagotavlja varnost.

Zmanjšuje izpostavljenost hlapnim organskim spojinam (HOS) in drugim nevarnim delcem med kemijskimi reakcijami in fazami mešanja, kar zagotavlja varnejše proizvodno okolje.

Zmanjšuje emisije prahu in hlapov med postopki pakiranja in distribucije, da se zagotovi, da končni izdelki ostanejo brez onesnaževalcev.

Regulativna krajina za nadzor prahu |

|---|

Skladnost s standardi kakovosti zraka |

Skladnost z varnostjo in zdravjem delavcev |

Preprečevanje nevarnosti požara in eksplozije |

Skladnost z varstvom okolja |

Spremljanje emisij v realnem času |

Toplotna in kemična odpornost |

Zmanjšani stroški izpadov in vzdrževanja |

Celovitost in doslednost izdelka |

Nižji operativni stroški |

Izzivi nadzora prahu |

|---|

Ravnanje z nevarnim prahom in hlapi |

Obvladovanje tveganj za dihala pri delavcih |

Izpolnjevanje strogih okoljskih predpisov |

Nevarnosti vžiga in eksplozije |

Ohranjanje kakovosti in čistosti izdelkov |

Korozivni materiali in ekstremne temperature |

Obraba opreme |

Visoka tvorba prahu in hlapov |

Izpad zaradi vzdrževanja sistema |

Ključni dejavniki za učinkovito zatiranje prahu |

|---|

Učinkovito zajemanje prahu in hlapov |

Kemična in toplotna odpornost |

Optimizirano upravljanje pretoka zraka in tlaka |

Napredni filtracijski materiali |

Redno vzdrževanje in pregledi |

Skladnost z regulativnimi standardi |

Rešitve za filtracijo po meri |

Zmanjševanje tveganja za nevarne kemikalije |

Prilagodljive konfiguracije sistema |

Povežite se z nami za strokovni posvet

Raziščite naše druge storitve!

Pogosto zastavljena vprašanja

Filtracijski sistemi, ki se uporabljajo v kemični predelavi, vključujejo vrečaste filtre za suho zbiranje prahu, elektrostatične filtre za ravnanje z emisijami finih delcev, mokre čistilnike za nadzor kislih plinov in hlapov ter kartušne filtre za manjše količine ali natančen nadzor kakovosti zraka. V procesih, ki vključujejo visoke temperature ali agresivne kemikalije, se uporabljajo tudi sistemi za filtracijo vročih plinov z uporabo sintranih kovinskih medijev. Vsaka rešitev je izbrana glede na naravo emisij, procesne pogoje in zahteve glede okoljske skladnosti.

Filtracijski sistemi v kemični proizvodnji izboljšujejo kakovost zraka z učinkovitim zajemanjem in odstranjevanjem trdnih delcev in onesnaževal, ki nastanejo med predelavo. Z zmanjševanjem emisij ti sistemi pomagajo obratom pri izpolnjevanju okoljskih predpisov in standardov, s čimer zmanjšujejo vpliv na okolje in spodbujajo varnejše delovno mesto.

Elektrostatski filtri (ESP) ponujajo visoko učinkovitost pri odstranjevanju drobnih delcev, saj dosegajo učinkovitost do 991 TP3T, kar je še posebej koristno v kemični proizvodnji, kjer emisije dimnih plinov pogosto vsebujejo drobne prašne delce. Zmožni so obvladovati velike količine plina in učinkovito delujejo pri visokih temperaturah. Poleg tega imajo ESP relativno nizke padce tlaka, kar ima za posledico manjšo porabo energije med delovanjem.