Pejabat

IBU PEJABAT

Jerman

- Penapis Intensif Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Jerman - +49 20534200990

PEJABAT WILAYAH

Great Britain

- Penapis Intensif Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

PEJABAT WILAYAH

Emiriah Arab Bersatu

- Penapis Intensif Himenviro Technologies FZE – LLC

Pusat Perniagaan, Zon Bebas Bandar Penerbitan Sharjah, Sharjah, UAE - +971-556074697

PEJABAT WILAYAH

India

- Penapis Intensif Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

PEJABAT WILAYAH

India

- Penapis Intensif Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

PEJABAT WILAYAH

India

- Penapis Intensif Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Penyelesaian Penapisan Udara dan Habuk Industri Kimia

Industri kimia melibatkan proses yang sering menghasilkan zarah bawaan udara, wap dan asap berbahaya yang boleh memberi kesan kepada keselamatan pekerja, kualiti produk dan kelestarian alam sekitar. Penyelesaian penapisan udara dan habuk kami direka khusus untuk menangani cabaran unik pembuatan kimia, menangkap zarah, gas dan asap kimia pada titik kritikal sepanjang pengeluaran. Daripada pengendalian bahan mentah hingga ke pembungkusan, sistem kami dibina untuk memastikan pematuhan dengan piawaian kawal selia yang ketat, melindungi pekerja daripada pendedahan dan melindungi alam sekitar sambil mengekalkan kecekapan operasi.

Proses Penapisan Habuk dalam Industri Kimia

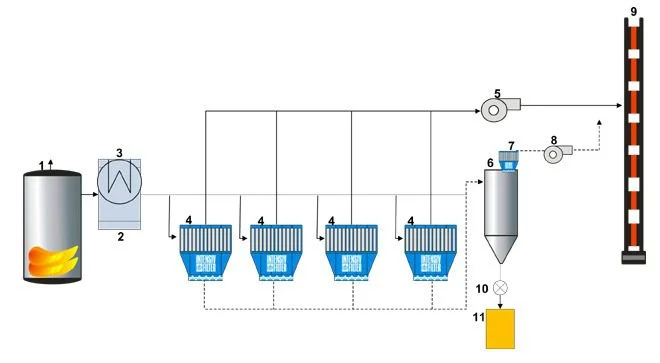

Perubahan iklim dan perlindungan iklim memainkan peranan yang semakin penting. Oleh itu pelbagai unit perniagaan industri kimia telah komited untuk mengurangkan pelepasan, contohnya ("Penjagaan Bertanggungjawab"). Berdasarkan contoh loji pembakaran sisa dalam syarikat kimia, habuk yang memaparkan sifat pembersihan sukar dialihkan daripada sistem. Precipitator penapisan digunakan untuk penyingkiran habuk gas buangan.

Penapis untuk relau pembakaran sisa

Penapis untuk relau pembakaran sisa

Penapis untuk relau pembakaran sisa

Penapis untuk relau pembakaran sisa

Penapis silo

- 1. Loji pembakaran

- 2. Dandang wap

- 3. Penukar haba

- 4. Penapis untuk relau pembakaran sisa

- 5. Kipas draf teraruh

- 6. Silo

- 7. Penapis silo

- 8. Ventilator penghantar

- 9. Cerobong asap

- 10. Pelepasan habuk

- 11. Pelupusan

Spesifikasi yang diperlukan

Data reka bentuk biasa | Relau pembakaran sisa |

|---|---|

Isipadu gas | 50 – 150,000 |

Suhu gas | 180 – 240 |

Jenis habuk | Abu terbang |

Kandungan habuk gas mentah | 5 |

Kandungan habuk yang tinggal | < 5 |

Pembersihan | penapis dalam talian |

Medium penapis | Kaca / Polytetrafluoroethylene |

Sorben | Kalsium hidroksida |

Aplikasi untuk Kawalan Habuk Industri Kimia

Menangkap habuk dan asap bawaan udara yang dijana semasa tindak balas kimia, pencampuran dan proses pembuatan lain, mengurangkan pendedahan kepada bahan kimia berbahaya.

Mengawal habuk semasa penyimpanan, pengendalian dan pemindahan bahan kimia mentah, mencegah pencemaran bawaan udara dan memastikan keselamatan.

Mengurangkan pendedahan kepada sebatian organik meruap (VOC) dan zarah berbahaya lain semasa tindak balas kimia dan peringkat pencampuran, memastikan persekitaran pengeluaran yang lebih selamat.

Meminimumkan pelepasan habuk dan asap semasa proses pembungkusan dan pengedaran untuk memastikan produk siap kekal bebas daripada bahan cemar.

Landskap Kawal Selia untuk Kawalan Habuk |

|---|

Pematuhan Standard Kualiti Udara |

Pematuhan Kesihatan & Keselamatan Pekerja |

Pencegahan Bahaya Kebakaran & Letupan |

Pematuhan Perlindungan Alam Sekitar |

Pemantauan Pelepasan Masa Nyata |

Rintangan Haba & Kimia |

Mengurangkan Masa Henti dan Kos Penyelenggaraan |

Integriti dan Konsistensi Produk |

Kos Operasi yang Lebih Rendah |

Cabaran Kawalan Habuk |

|---|

Mengendalikan Habuk dan Wap Berbahaya |

Menguruskan Risiko Pernafasan untuk Pekerja |

Memenuhi Peraturan Persekitaran yang Ketat |

Bahaya Pembakaran dan Letupan |

Mengekalkan Kualiti dan Kesucian Produk |

Bahan Menghakis dan Suhu Melampau |

Haus dan Lusuh Peralatan |

Penjanaan Habuk dan Wasap Tinggi |

Masa Henti Disebabkan Penyelenggaraan Sistem |

Pertimbangan Utama untuk Kawalan Habuk yang Berkesan |

|---|

Tangkapan Habuk dan Wasap yang Cekap |

Rintangan Kimia dan Haba |

Aliran Udara dan Pengurusan Tekanan yang Dioptimumkan |

Bahan Penapisan Lanjutan |

Penyelenggaraan & Pemeriksaan Rutin |

Pematuhan Piawaian Kawal Selia |

Penyelesaian Penapisan Tersuai |

Pengurangan Risiko untuk Bahan Kimia Berbahaya |

Konfigurasi Sistem Fleksibel |

Berhubung dengan kami untuk Perundingan Pakar

Terokai Perkhidmatan Kami yang Lain!

Soalan Lazim

Sistem penapisan yang digunakan dalam pemprosesan kimia termasuk penapis baghouse untuk pengumpulan habuk kering, precipitator elektrostatik untuk mengendalikan pelepasan zarah halus, penyental basah untuk mengawal gas asid dan wap, dan penapis kartrij untuk volum yang lebih kecil atau kawalan kualiti udara ketepatan. Dalam proses yang melibatkan suhu tinggi atau bahan kimia yang agresif, sistem penapisan gas panas menggunakan media logam tersinter juga digunakan. Setiap penyelesaian dipilih berdasarkan sifat pelepasan, keadaan proses dan keperluan pematuhan alam sekitar.

Sistem penapisan dalam pembuatan kimia meningkatkan kualiti udara dengan menangkap dan menyingkirkan bahan zarah dan bahan pencemar yang dijana secara berkesan semasa pemprosesan. Dengan mengurangkan pelepasan, sistem ini membantu kemudahan mematuhi peraturan dan piawaian alam sekitar, dengan itu meminimumkan kesan alam sekitar dan mempromosikan tempat kerja yang lebih selamat.

ESP menawarkan kecekapan tinggi dalam mengeluarkan zarah halus, mencapai kecekapan sehingga 99%, yang amat bermanfaat dalam pengeluaran kimia di mana pelepasan gas serombong selalunya mengandungi zarah habuk halus. Mereka mampu mengendalikan isipadu gas yang besar dan beroperasi dengan berkesan pada suhu tinggi. Selain itu, ESP mempunyai penurunan tekanan yang agak rendah, menyebabkan penggunaan tenaga yang lebih rendah semasa operasi.