Kantor

KANTOR PUSAT

Jerman

- Filter Intensif Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Jerman/Jerman - +49 20534200990

KANTOR WILAYAH

Britania Raya

- Filter Intensif Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Inggris Raya - +44 1922 628893

KANTOR WILAYAH

Uni Emirat Arab

- Filter Intensif Himenviro Technologies FZE – LLC

Pusat Bisnis, Zona Bebas Kota Penerbitan Sharjah, Sharjah, UEA - +971-556074697

KANTOR WILAYAH

India

- Filter Intensif Himenviro Private Limited

D-247/11, Sektor-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

KANTOR WILAYAH

India

- Filter Intensif Himenviro Private Limited

D-247/11, Sektor-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

KANTOR WILAYAH

India

- Filter Intensif Himenviro Private Limited

D-247/11, Sektor-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Solusi Filtrasi Udara dan Debu Industri Kimia

Industri kimia melibatkan proses yang seringkali menghasilkan partikel, uap, dan asap berbahaya di udara yang dapat memengaruhi keselamatan pekerja, kualitas produk, dan keberlanjutan lingkungan. Solusi penyaringan udara dan debu kami dirancang khusus untuk mengatasi tantangan unik dalam manufaktur kimia, menangkap partikel, gas, dan asap kimia di titik-titik kritis selama produksi. Dari penanganan bahan baku hingga pengemasan, sistem kami dirancang untuk memastikan kepatuhan terhadap standar peraturan yang ketat, melindungi pekerja dari paparan, dan menjaga lingkungan sekaligus menjaga efisiensi operasional.

Proses Filtrasi Debu dalam Industri Kimia

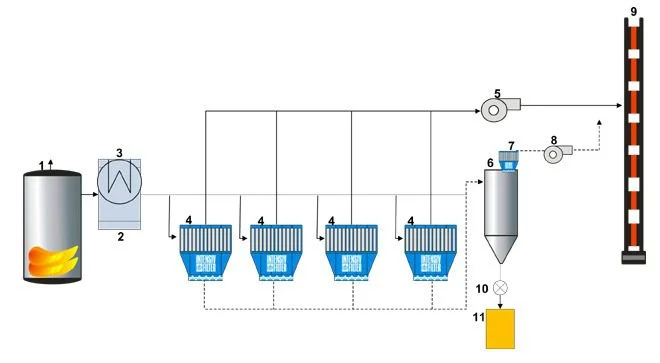

Perubahan Iklim dan perlindungan iklim memainkan peran yang semakin penting. Oleh karena itu berbagai unit bisnis industri kimia telah berkomitmen untuk mengurangi emisi, misalnya (“Responsible Care”). Berdasarkan contoh pabrik pembakaran residu di perusahaan kimia, debu yang memiliki sifat pembersihan yang sulit dihilangkan dari sistem. Precipitator penyaring digunakan untuk menghilangkan debu gas buang.

Filter untuk tungku pembakaran residu

Filter untuk tungku pembakaran residu

Filter untuk tungku pembakaran residu

Filter untuk tungku pembakaran residu

saringan silo

- 1. Instalasi pembakaran

- 2. Ketel uap

- 3. Penukar panas

- 4. Filter untuk sisa pembakaran tungku

- 5. Kipas angin induksi

- 6. Silo

- 7. Saringan silo

- 8. Ventilasi konveyor

- 9. Cerobong asap

- 10. Keluarnya debu

- 11. Pembuangan

Spesifikasi yang dibutuhkan

Data desain tipikal | Tungku pembakaran residu |

|---|---|

Volume gasnya | 50 – 150.000 |

Suhu gas | 180 – 240 |

Jenis debu | Abu terbang |

Kandungan debu gas mentah | 5 |

Kandungan debu sisa | < 5 |

Pembersihan | penyaring daring |

Media penyaring | Kaca / Polytetrafluoroetilena |

Penyerap | Kalsium hidroksida |

Aplikasi untuk Pengendalian Debu Industri Kimia

Menangkap debu dan asap di udara yang dihasilkan selama reaksi kimia, pencampuran, dan proses manufaktur lainnya, sehingga mengurangi paparan terhadap bahan kimia berbahaya.

Mengontrol debu selama penyimpanan, penanganan, dan pemindahan bahan kimia mentah, mencegah kontaminasi di udara dan memastikan keselamatan.

Mengurangi paparan senyawa organik yang mudah menguap (VOC) dan partikel berbahaya lainnya selama reaksi kimia dan tahap pencampuran, memastikan lingkungan produksi yang lebih aman.

Meminimalkan emisi debu dan asap selama proses pengemasan dan distribusi untuk memastikan produk akhir bebas kontaminan.

Lanskap Regulasi untuk Pengendalian Debu |

|---|

Kepatuhan Standar Kualitas Udara |

Kepatuhan Kesehatan & Keselamatan Pekerja |

Pencegahan Bahaya Kebakaran & Ledakan |

Kepatuhan Perlindungan Lingkungan |

Pemantauan Emisi Waktu Nyata |

Tahan Panas & Kimia |

Mengurangi Waktu Henti dan Biaya Perawatan |

Integritas dan Konsistensi Produk |

Biaya Operasional yang Lebih Rendah |

Tantangan Pengendalian Debu |

|---|

Penanganan Debu dan Uap Berbahaya |

Mengelola Risiko Pernapasan bagi Pekerja |

Memenuhi Peraturan Lingkungan yang Ketat |

Bahaya Pembakaran dan Ledakan |

Menjaga Kualitas dan Kemurnian Produk |

Bahan Korosif dan Suhu Ekstrim |

Keausan Peralatan |

Generasi Debu dan Asap Tinggi |

Waktu Henti Karena Pemeliharaan Sistem |

Pertimbangan Utama untuk Pengendalian Debu yang Efektif |

|---|

Penangkapan Debu dan Asap yang Efisien |

Tahan Kimia dan Panas |

Manajemen Aliran Udara dan Tekanan yang Dioptimalkan |

Bahan Filtrasi Canggih |

Perawatan dan Inspeksi Rutin |

Kepatuhan terhadap Standar Peraturan |

Solusi Filtrasi yang Disesuaikan |

Mitigasi Risiko Bahan Kimia Berbahaya |

Konfigurasi Sistem yang Fleksibel |

Hubungi kami untuk Konsultasi Ahli

Jelajahi Layanan Kami Lainnya!

Pertanyaan yang Sering Diajukan

Sistem filtrasi yang digunakan dalam pemrosesan kimia meliputi filter baghouse untuk pengumpulan debu kering, presipitator elektrostatik untuk menangani emisi partikulat halus, scrubber basah untuk mengendalikan gas dan uap asam, dan filter kartrid untuk volume yang lebih kecil atau pengendalian kualitas udara presisi. Dalam proses yang melibatkan suhu tinggi atau bahan kimia agresif, sistem filtrasi gas panas menggunakan media logam sinter juga diterapkan. Setiap solusi dipilih berdasarkan sifat emisi, kondisi proses, dan persyaratan kepatuhan lingkungan.

Sistem filtrasi dalam proses produksi kimia meningkatkan kualitas udara dengan menangkap dan menghilangkan partikel dan polutan yang dihasilkan selama proses secara efektif. Dengan mengurangi emisi, sistem ini membantu fasilitas mematuhi peraturan dan standar lingkungan, sehingga meminimalkan dampak lingkungan dan menciptakan tempat kerja yang lebih aman.

ESP menawarkan efisiensi tinggi dalam menghilangkan partikel halus, mencapai efisiensi hingga 99%, yang khususnya bermanfaat dalam produksi kimia di mana emisi gas buang sering mengandung partikel debu halus. ESP mampu menangani volume gas yang besar dan beroperasi secara efektif pada suhu tinggi. Selain itu, ESP memiliki penurunan tekanan yang relatif rendah, sehingga menghasilkan konsumsi energi yang lebih rendah selama operasi.