Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

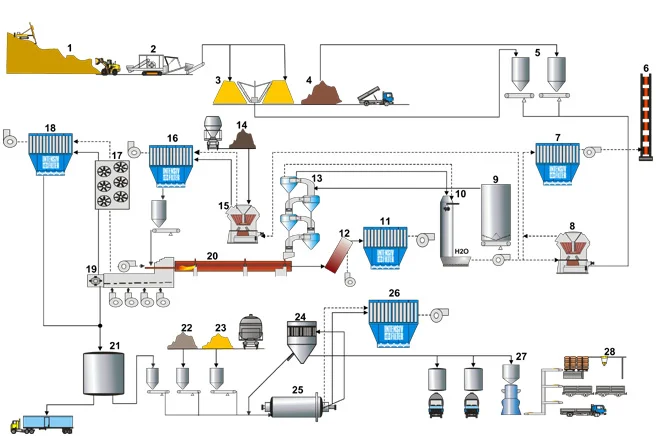

Bag Filters Use Cases in Cement Production Process

Külső szűrő

Permetező szárító

CIP szűrő

Külső fluidágy

Töltő

- 1. Kőbánya

- 2. Daráló üzem

- 3. Nyersanyag homogenizálás

- 4. Aggregátumok

- 5. Nyers malom etetősiló

- 6. Fő verem

- 7. Zsákos szűrő kemence-/nyers malomhoz

- 8. Függőleges nyers malom

- 9. Nyersanyag adagoló siló

- 10. Gázkondicionáló torony

- 11. Zsákos szűrő lúgátvezetéshez

- 12. Bypass keverőkamra

- 13. Ciklon előmelegítő

- 14. Nyers szén

- 15. Függőleges szénőrlő malom

- 16. Zsákos szűrő széndaráló üzemhez

- 17. Csőhűtő

- 18. Zsákos szűrő klinkerhűtőhöz

- 19. Klinkerhűtő

- 20. Rotációs kemence

- 21. Klinkersiló

- 22. Gipsz

- 23. Ásványi anyagok

- 24. Elválasztó

- 25. Cement kidolgozó malom

- 26. Zsákos szűrő cementsimító malomhoz

- 27. Csomagoló üzem

- 28. Raklapozó üzem

Kötelező specifikáció

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Tipikus tervezési adatok | Kemence-/nyers malom |

|---|---|

Gáz térfogata | < 1 200 000 |

Gáz hőmérséklet | 85 – 110 összetett / < 250 közvetlen |

A por típusa | CaCO3, CaO |

Maradék portartalom | < 550 |

Nyers gáz por tartalom | < 10 |

Tisztítás | online / offline |

Szűrőközeg | PEA, NX, PPS, PI, GL/PTFE |

Tipikus tervezési adatok | Alkáli bypass |

|---|---|

Gáz térfogata | < 800 000 |

Gáz hőmérséklet | < 250 |

A por típusa | CaCO3, CaO, lúg |

Maradék portartalom | < 25 |

Nyers gáz por tartalom | < 10 |

Tisztítás | offline módban |

Szűrőközeg | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Tipikus tervezési adatok | Szénmalom |

|---|---|

Gáz térfogata | < 450 000 |

Gáz hőmérséklet | 80-110 |

A por típusa | Szén |

Maradék portartalom | < 250 |

Nyers gáz por tartalom | < 10 |

Tisztítás | online |

Szűrőközeg | PEA / PAN |

Tipikus tervezési adatok | Cső alakú hűtő |

|---|---|

Gáz térfogata | < 1 600 000 |

A gáz hőmérséklete be | 250-350 |

A gáz hőmérséklete ki | 120-200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Tipikus tervezési adatok | Klinker hűtő |

|---|---|

Gáz térfogata | < 800 000 |

Gáz hőmérséklet | 120-180 |

A por típusa | Klinkertégla |

Nyers gáz por tartalom | 10-30 |

Maradék portartalom | < 10 |

Tisztítás | online |

Szűrőközeg | PE / NX /PI |

Tipikus tervezési adatok | Cement befejező malom |

|---|---|

Gáz térfogata | < 300 000 |

Gáz hőmérséklet | 80-110 |

A por típusa | Cement, salak |

Nyers gáz por tartalom | <350 |

Maradék portartalom | < 10 |

Tisztítás | online / offline |

Szűrőközeg | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Szabályozza a nagy energiájú zúzás és őrlés során keletkező port, felfogja a finom részecskéket, hogy azok ne kerüljenek a légkörbe.

Csökkenti a nyersanyagok melegítésével járó kemencei folyamatok kibocsátását, szabályozva a cementgyártás során felszabaduló port és egyéb levegőben szálló részecskéket.

Megköti a port az ömlesztett anyagok, például a mészkő és a klinker szállítása során, hogy megakadályozza a részecskék felszabadulását a tárolási és szállítási szakaszokban.

Minimalizálja a porkibocsátást a termékek csomagolásán és tárolásán, biztosítva, hogy a késztermékek szennyeződésmentes környezetben csomagolhatók és tárolhatók.

Szabályozási környezet a porszabályozáshoz |

|---|

Levegőminőségi szabványok |

Munkavállalói egészség és biztonság |

Tűz- és robbanásvédelem |

Környezetvédelem |

Kibocsátás-monitorozás és -jelentés |

Energiahatékonyság |

Hulladékgazdálkodás |

Termékminőség és következetesség |

Csökkentett állásidő és karbantartási költségek |

Porszabályozási kihívások |

|---|

Magas porszint |

Munkavállalói egészségügyi kockázatok |

Környezetvédelmi megfelelés |

Tűz- és robbanásveszélyek |

Termékminőségi aggályok |

Berendezések kopása |

Keresztszennyeződés |

Levegőminőségi megfelelőség |

Mikrobiális növekedés |

A hatékony porszabályozás fő szempontjai |

|---|

Hatékony porgyűjtő rendszerek bevezetése |

Megfelelő légáramlás és nyomásszabályozás |

Hőmérséklet- és nedvességszabályozás |

Nagy hatékonyságú szűrőrendszerek |

Rendszeres karbantartás és ellenőrzés |

Iparági szabványok betartása |

A portalanító rendszer gyakori értékelése |

Folyamatspecifikus adaptációk |

Kockázatértékelés és -csökkentés |

Forduljon hozzánk szakértői konzultációért

Fedezze fel egyéb szolgáltatásainkat!

Gyakran Ismételt Kérdések

A cementiparban a hatékony szűrési megoldások elengedhetetlenek a porkibocsátás szabályozásához és a környezetvédelmi előírások betartásához. Az általánosan használt szűrőrendszerek közé tartoznak a zsákos szűrők, amelyek szövetszűrő zsákokat használnak a finom részecskék felfogására különböző folyamatokból, például kemencékből, malmokból és anyagmozgatásból. Ezeket a szűrőket a részecskék eltávolításában való nagy hatékonyságuk miatt kedvelik. Ezenkívül a fejlett szűrési megoldások, mint például a Micronics által kínáltak, a cementipar egyedi igényeinek kielégítésére szolgálnak, biztosítva a környezetvédelmi előírások betartását és növelve a működési hatékonyságot.

A szűrőrendszerek javítják a cementgyártás hatékonyságát azáltal, hogy hatékonyan felfogják a port és a szilárd részecskéket, csökkentik a berendezések kopását és megelőzik az eltömődéseket. Ez biztosítja a zökkenőmentes működést, minimalizálja az állásidőt, és a szennyeződés megelőzésével javítja a termékminőséget. A megfelelő porszabályozás a szabályozási előírásoknak való megfelelés fenntartásában is segít, csökkentve a bírságok és a környezeti problémák kockázatát. Ezenkívül a hatékony szűrőrendszerek hozzájárulnak az energiamegtakarításhoz azáltal, hogy optimalizálják a légáramlást és csökkentik a nyomásesést a rendszerben.

A cementgyártásban alkalmazott fejlett szűrőrendszerek segítenek csökkenteni a levegőszennyezést azáltal, hogy felfogják a finom porrészecskéket és minimalizálják a káros szennyező anyagok kibocsátását. Javítják a levegőminőséget, biztosítják a környezetvédelmi előírások betartását és csökkentik az iparág szénlábnyomát. A porszabályozás fokozásával ezek a rendszerek hozzájárulnak a munkavállalók egészségéhez és biztonságához is. Ezenkívül támogatják a fenntarthatóságot azáltal, hogy lehetővé teszik a nyersanyagok visszanyerését és újrafelhasználását, csökkentik a hulladékot, és optimalizálják az energiahatékonyságot a cementgyártási folyamatokban.