Toimistot

PÄÄKONTO

Saksa

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45-49, 42553, Velbert, Deutschland/Saksa - +49 20534200990

ALUETOIMISTO

Iso-Britannia

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Iso-Britannia - +44 1922 628893

ALUETOIMISTO

Yhdistyneet arabiemiirikunnat

- Intensiivinen suodatin Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, Arabiemiirikunnat - +971-556074697

ALUETOIMISTO

Intia

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Intia - +91-120-4642-500

ALUETOIMISTO

Intia

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Intia - +91-120-4642-500

ALUETOIMISTO

Intia

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Intia - +91-120-4642-500

Kemianteollisuuden ilman- ja pölynsuodatusratkaisut

Kemianteollisuudessa käytetään prosesseja, jotka usein tuottavat vaarallisia ilmassa olevia hiukkasia, höyryjä ja savukaasuja, jotka voivat vaikuttaa työntekijöiden turvallisuuteen, tuotteiden laatuun ja ympäristön kestävyyteen. Ilman- ja pölynsuodatusratkaisumme on erityisesti suunniteltu vastaamaan kemianteollisuuden ainutlaatuisiin haasteisiin ja keräämään hiukkasia, kaasuja ja kemiallisia höyryjä kriittisissä vaiheissa koko tuotannon ajan. Raaka-aineiden käsittelystä pakkaamiseen järjestelmämme on rakennettu varmistamaan tiukkojen sääntelystandardien noudattaminen, suojaamaan työntekijöitä altistumiselta ja suojelemaan ympäristöä samalla, kun ylläpidetään toiminnan tehokkuutta.

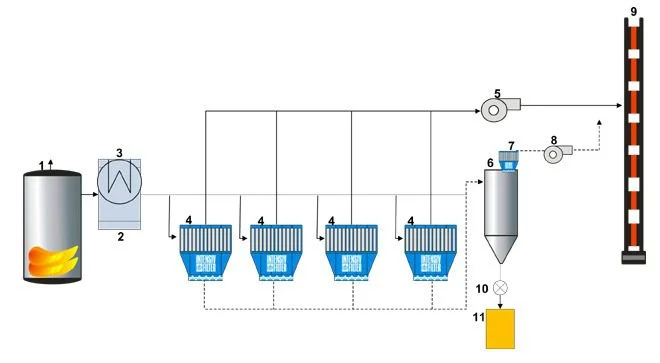

Pölynsuodatusprosessi kemianteollisuudessa

Ilmastonmuutos ja ilmastonsuojelu niillä on yhä tärkeämpi rooli. Siksi kemianteollisuuden eri liiketoimintayksiköt ovat sitoutuneet esimerkiksi vähentämään päästöjä ("Responsible Care"). Kemianteollisuuden jätteenpolttolaitoksen esimerkin perusteella järjestelmästä poistetaan vaikeita puhdistusominaisuuksia omaava pöly. Suodatussuodatinta käytetään savukaasupölyn poistoon.

Suodatin jäännöspolttouuniin

Suodatin jäännöspolttouuniin

Suodatin jäännöspolttouuniin

Suodatin jäännöspolttouuniin

Siilon suodatin

- 1. Polttolaitos

- 2. Höyrykattila

- 3. Lämmönvaihdin

- 4. Jäännöspolttouunin suodatin

- 5. Indusoitu vetopuhallin

- 6. Siilo

- 7. Siilonsuodatin

- 8. Kuljetintuuletin

- 9. Savupiippu

- 10. Pölypurkaus

- 11. Hävittäminen

Vaaditut tiedot

Tyypillisiä suunnittelutietoja | Jäännöspolttouunit |

|---|---|

Kaasun tilavuus | 50-150 000 |

Kaasun lämpötila | 180-240 |

Pölyn tyyppi | Lentotuhka |

Raakakaasun pölypitoisuus | 5 |

Jäännöspölypitoisuus | <5 |

Puhdistus | online-suodatin |

Suodatinväline | Lasi / polytetrafluorieteeni |

Sorbentti | Kalsiumhydroksidi |

Kemianteollisuuden pölynhallinnan sovellukset

Kerää ilmassa leijuvaa pölyä ja höyryjä, joita syntyy kemiallisten reaktioiden, sekoittamisen ja muiden valmistusprosessien aikana, vähentäen altistumista haitallisille kemikaaleille.

Hallitsee pölyä raaka-aineiden varastoinnin, käsittelyn ja siirron aikana estäen ilmateitse leviävän kontaminaation ja varmistaen turvallisuuden.

Vähentää altistumista haihtuville orgaanisille yhdisteille (VOC) ja muille vaarallisille hiukkasille kemiallisen reaktion ja sekoitusvaiheiden aikana varmistaen turvallisemman tuotantoympäristön.

Minimoi pöly- ja höyrypäästöt pakkaus- ja jakeluprosessien aikana varmistaakseen, että valmiit tuotteet pysyvät epäpuhtauksina.

Pölyn torjunnan sääntelymaisema |

|---|

Ilmanlaatustandardien noudattaminen |

Työntekijöiden terveys- ja turvallisuusmääräysten noudattaminen |

Palo- ja räjähdysvaaran ehkäisy |

Ympäristönsuojelun vaatimustenmukaisuus |

Reaaliaikainen päästöjen seuranta |

Lämmön- ja kemikaalienkestävyys |

Lyhemmät seisokkiajat ja ylläpitokustannukset |

Tuotteen eheys ja johdonmukaisuus |

Alemmat käyttökustannukset |

Pölynhallinnan haasteet |

|---|

Vaarallisen pölyn ja höyryjen käsittely |

Työntekijöiden hengitystieriskien hallinta |

Tiukkojen ympäristömääräysten noudattaminen |

Palamis- ja räjähdysvaarat |

Tuotteen laadun ja puhtauden ylläpitäminen |

Syövyttävät materiaalit ja äärimmäiset lämpötilat |

Laitteiden kuluminen |

Paljon pölyä ja höyryjä |

Järjestelmän huollosta johtuva seisokkiaika |

Tehokkaan pölynhallinnan keskeiset näkökohdat |

|---|

Tehokas pölyn ja savun talteenotto |

Kemikaalien ja lämmönkestävyys |

Optimoitu ilmavirran ja paineen hallinta |

Edistyneet suodatusmateriaalit |

Rutiinihuolto ja tarkastukset |

Sääntelystandardien noudattaminen |

Räätälöidyt suodatusratkaisut |

Vaarallisten kemikaalien riskien minimointi |

Joustavat järjestelmäkokoonpanot |

Ota yhteyttä asiantuntijakonsultaatioon

Tutustu muihin palveluihimme!

Usein kysytyt kysymykset

Kemianteollisuudessa käytettäviin suodatusjärjestelmiin kuuluvat pussisuodattimet kuivan pölyn keräämiseen, sähköstaattiset saostimet hienojen hiukkaspäästöjen käsittelyyn, märkäpesurit happamien kaasujen ja höyryjen hallintaan sekä patruunasuodattimet pienempiin tilavuuksiin tai tarkkaan ilmanlaadun hallintaan. Korkeissa lämpötiloissa tai aggressiivisissa kemikaaleissa käytetään myös sintrattuja metallisuodattimia käyttäviä kuumakaasusuodatusjärjestelmiä. Jokainen ratkaisu valitaan päästöjen luonteen, prosessiolosuhteiden ja ympäristövaatimusten perusteella.

Kemianteollisuuden suodatusjärjestelmät parantavat ilmanlaatua talteenottamalla ja poistamalla tehokkaasti prosessoinnin aikana syntyviä hiukkasia ja epäpuhtauksia. Vähentämällä päästöjä nämä järjestelmät auttavat laitoksia noudattamaan ympäristömääräyksiä ja -standardeja, mikä minimoi niiden ympäristövaikutukset ja edistää turvallisempaa työpaikkaa.

Sähkösuodinsuodimet tarjoavat korkean tehokkuuden hienojen hiukkasten poistamisessa, saavuttaen jopa 99%-hyötysuhteen, mikä on erityisen hyödyllistä kemianteollisuudessa, jossa savukaasupäästöt sisältävät usein hienoja pölyhiukkasia. Ne pystyvät käsittelemään suuria kaasumääriä ja toimivat tehokkaasti korkeissa lämpötiloissa. Lisäksi sähkösuodinsuodinten painehäviöt ovat suhteellisen pienet, mikä johtaa pienempään energiankulutukseen käytön aikana.