Oficinas

SEDE CENTRAL

Alemania

- Filtro intensivo Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Alemania - +49 20534200990

OFICINA REGIONAL

Gran Bretaña

- Filtro intensivo Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Gran Bretaña - +44 1922 628893

OFICINA REGIONAL

Emiratos Árabes Unidos

- Filtro intensivo Himenviro Technologies FZE – LLC

Centro de negocios, Zona franca de Sharjah Publishing City, Sharjah, Emiratos Árabes Unidos - +971-556074697

OFICINA REGIONAL

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

OFICINA REGIONAL

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

OFICINA REGIONAL

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Soluciones de filtración de aire y polvo para la industria química

La industria química implica procesos que a menudo generan partículas, vapores y humos peligrosos en el aire que pueden afectar la seguridad de los trabajadores, la calidad de los productos y la sostenibilidad ambiental. Nuestras soluciones de filtración de aire y polvo están diseñadas específicamente para abordar los desafíos únicos de la fabricación de productos químicos, capturando partículas, gases y humos químicos en puntos críticos de la producción. Desde la manipulación de materias primas hasta el envasado, nuestros sistemas están diseñados para garantizar el cumplimiento de estrictas normas regulatorias, proteger a los trabajadores de la exposición y proteger el medio ambiente, manteniendo al mismo tiempo la eficiencia operativa.

Proceso de filtración de polvo en la industria química

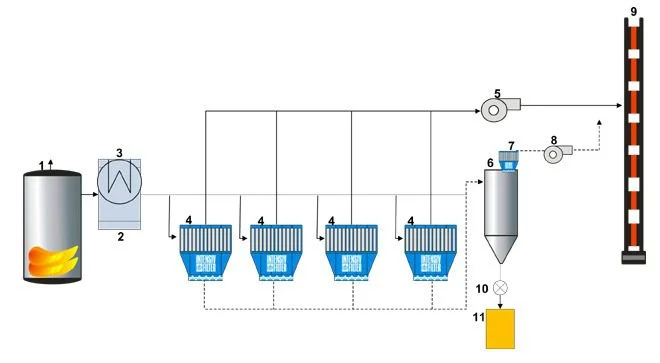

El cambio climático y protección del clima Los gases de escape desempeñan un papel cada vez más importante. Por ello, las distintas unidades de negocio de la industria química se han comprometido, por ejemplo, a reducir las emisiones («Responsible Care»). Tomando como ejemplo una planta de combustión de residuos de una empresa química, se elimina del sistema el polvo con propiedades de limpieza difíciles. Para la eliminación del polvo de los gases de escape se utiliza un precipitador filtrante.

Filtro para horno de combustión de residuos

Filtro para horno de combustión de residuos

Filtro para horno de combustión de residuos

Filtro para horno de combustión de residuos

Filtro de silo

- 1. Planta de combustión

- 2. Caldera de vapor

- 3. Intercambiador de calor

- 4. Filtro para horno de combustión de residuos

- 5. Ventilador de tiro inducido

- 6. Silo

- 7. Filtro de silo

- 8. Ventilador de cinta transportadora

- 9. Chimenea

- 10. Descarga de polvo

- 11. Eliminación

Especificaciones requeridas

Datos de diseño típicos | Hornos de combustión de residuos |

|---|---|

Volumen de gas | 50 – 150.000 |

Temperatura del gas | 180 – 240 |

Tipo de polvo | Cenizas volantes |

Contenido de polvo de gas crudo | 5 |

Contenido de polvo residual | < 5 |

Limpieza | filtro en línea |

Medio filtrante | Vidrio / Politetrafluoroetileno |

Absorbente | Hidróxido de calcio |

Aplicaciones para el control del polvo en la industria química

Captura el polvo y los humos en el aire generados durante reacciones químicas, mezclas y otros procesos de fabricación, reduciendo la exposición a productos químicos nocivos.

Controla el polvo durante el almacenamiento, manipulación y transferencia de productos químicos crudos, previniendo la contaminación del aire y garantizando la seguridad.

Reduce la exposición a compuestos orgánicos volátiles (COV) y otras partículas peligrosas durante las etapas de reacción química y mezcla, garantizando un entorno de producción más seguro.

Minimiza las emisiones de polvo y humo durante los procesos de envasado y distribución para garantizar que los productos terminados permanezcan libres de contaminantes.

Panorama regulatorio para el control del polvo |

|---|

Cumplimiento de las normas de calidad del aire |

Cumplimiento de la salud y seguridad del trabajador |

Prevención de riesgos de incendio y explosión |

Cumplimiento de la protección ambiental |

Monitoreo de emisiones en tiempo real |

Resistencia al calor y a los productos químicos |

Reducción de tiempos de inactividad y costos de mantenimiento |

Integridad y consistencia del producto |

Costos operativos más bajos |

Desafíos del control del polvo |

|---|

Manejo de polvos y vapores peligrosos |

Gestión de riesgos respiratorios para los trabajadores |

Cumplimiento de estrictas regulaciones ambientales |

Peligros de combustión y explosión |

Mantener la calidad y pureza del producto |

Materiales corrosivos y temperaturas extremas |

Desgaste del equipo |

Alta generación de polvo y humo |

Tiempo de inactividad debido al mantenimiento del sistema |

Consideraciones clave para un control eficaz del polvo |

|---|

Captura eficiente de polvo y humos |

Resistencia química y térmica |

Gestión optimizada del flujo de aire y la presión |

Materiales de filtración avanzados |

Mantenimiento y inspecciones de rutina |

Cumplimiento de las normas regulatorias |

Soluciones de filtración personalizadas |

Mitigación de riesgos para productos químicos peligrosos |

Configuraciones de sistema flexibles |

Conéctese con nosotros para una consulta con expertos

¡Explora nuestros otros servicios!

Preguntas frecuentes

Los sistemas de filtración utilizados en el procesamiento químico incluyen filtros de mangas para la recolección de polvo seco, precipitadores electrostáticos para el manejo de emisiones de partículas finas, depuradores húmedos para el control de gases y vapores ácidos, y filtros de cartucho para volúmenes más pequeños o para el control preciso de la calidad del aire. En procesos que implican altas temperaturas o productos químicos agresivos, también se aplican sistemas de filtración de gases calientes con medios metálicos sinterizados. Cada solución se selecciona en función de la naturaleza de las emisiones, las condiciones del proceso y los requisitos de cumplimiento ambiental.

Los sistemas de filtración en la industria química mejoran la calidad del aire al capturar y eliminar eficazmente las partículas y los contaminantes generados durante el procesamiento. Al reducir las emisiones, estos sistemas ayudan a las instalaciones a cumplir con las normativas y estándares ambientales, minimizando así su impacto ambiental y promoviendo un entorno de trabajo más seguro.

Los precipitadores electrostáticos (PE) ofrecen una alta eficiencia en la eliminación de partículas finas, alcanzando una eficiencia de hasta 99%, lo cual resulta especialmente beneficioso en la producción química, donde las emisiones de gases de combustión suelen contener partículas finas de polvo. Son capaces de manejar grandes volúmenes de gas y operar eficazmente a altas temperaturas. Además, los PE presentan caídas de presión relativamente bajas, lo que se traduce en un menor consumo de energía durante su funcionamiento.