Standorte

HAUPTSITZ

Deutschland

- Intensivfilter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Deutschland - +49 20534200990

REGIONALBÜRO

Großbritannien

- Intensivfilter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Großbritannien - +44 1922 628893

REGIONALBÜRO

Vereinigte Arabische Emirate

- Intensivfilter Himenviro Technologies FZE – LLC

Geschäftszentrum, Sharjah Publishing City Free Zone, Sharjah, Vereinigte Arabische Emirate - +971-556074697

REGIONALBÜRO

Indien

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida – 201301, Uttar Pradesh, Indien - +91-120-4642-500

REGIONALBÜRO

Indien

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida – 201301, Uttar Pradesh, Indien - +91-120-4642-500

REGIONALBÜRO

Indien

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida – 201301, Uttar Pradesh, Indien - +91-120-4642-500

Luft- und Staubfiltrationslösungen für die chemische Industrie

In der chemischen Industrie entstehen bei Prozessen häufig gefährliche Partikel, Dämpfe und Rauch, die die Arbeitssicherheit, die Produktqualität und die Umweltverträglichkeit beeinträchtigen können. Unsere Luft- und Staubfilterlösungen sind speziell auf die besonderen Herausforderungen der chemischen Produktion zugeschnitten und erfassen Partikel, Gase und chemische Dämpfe an kritischen Stellen der Produktion. Von der Rohstoffhandhabung bis zur Verpackung sind unsere Systeme so konzipiert, dass sie die Einhaltung strenger gesetzlicher Vorschriften gewährleisten, Mitarbeiter vor Belastungen schützen und die Umwelt schonen – bei gleichzeitiger Wahrung der Betriebseffizienz.

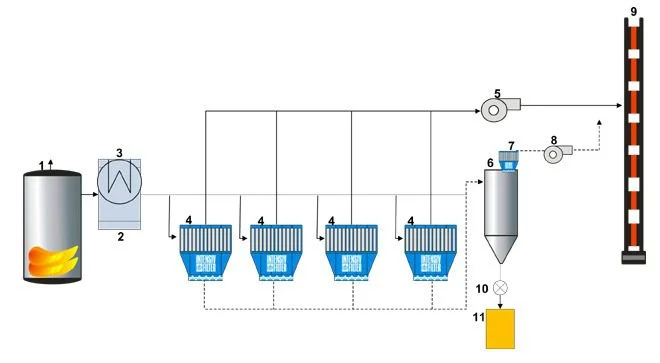

Staubfiltrationsprozess in der chemischen Industrie

Klimawandel und Klimaschutz spielen eine immer größere Rolle. So haben sich beispielsweise die verschiedenen Geschäftsbereiche der chemischen Industrie dazu verpflichtet, Emissionen zu reduzieren („Responsible Care“). Am Beispiel einer Rückstandsverbrennungsanlage in einem Chemieunternehmen werden schwer zu reinigende Stäube aus dem System entfernt. Zur Abgasentstaubung wird ein filternder Abscheider eingesetzt.

Filter für Rückstandsverbrennungsofen

Filter für Rückstandsverbrennungsofen

Filter für Rückstandsverbrennungsofen

Filter für Rückstandsverbrennungsofen

Silofilter

- 1. Feuerungsanlage

- 2. Dampfkessel

- 3. Wärmetauscher

- 4. Filter für Rückstandsverbrennungsofen

- 5. Saugzuggebläse

- 6. Silo

- 7. Silofilter

- 8. Förderbandventilator

- 9. Schornstein

- 10. Staubaustrag

- 11. Entsorgung

Erforderliche Spezifikationen

Typische Auslegungsdaten | Rückstandsverbrennungsöfen |

|---|---|

Gasvolumen | 50 – 150.000 |

Gastemperatur | 180 – 240 |

Staubart | Flugasche |

Rohgasstaubgehalt | 5 |

Reststaubgehalt | < 5 |

Reinigung | Online-Filter |

Filtermedium | Glas / Polytetrafluorethylen |

Sorptionsmittel | Calciumhydroxid |

Anwendungen zur Staubkontrolle in der chemischen Industrie

Fängt Staub und Dämpfe aus der Luft ein, die bei chemischen Reaktionen, beim Mischen und anderen Herstellungsprozessen entstehen, und verringert so die Belastung durch schädliche Chemikalien.

Kontrolliert den Staub während der Lagerung, Handhabung und Übertragung von Rohchemikalien, verhindert so eine Kontamination durch die Luft und gewährleistet die Sicherheit.

Reduziert die Belastung durch flüchtige organische Verbindungen (VOCs) und andere gefährliche Partikel während der chemischen Reaktions- und Mischphasen und sorgt so für eine sicherere Produktionsumgebung.

Minimiert Staub- und Rauchemissionen während der Verpackungs- und Vertriebsprozesse, um sicherzustellen, dass die fertigen Produkte frei von Verunreinigungen bleiben.

Regulierungsrahmen für die Staubkontrolle |

|---|

Einhaltung von Luftqualitätsstandards |

Einhaltung der Gesundheits- und Sicherheitsvorschriften für Arbeitnehmer |

Brand- und Explosionsschutz |

Einhaltung des Umweltschutzes |

Emissionsüberwachung in Echtzeit |

Hitze- und Chemikalienbeständigkeit |

Reduzierte Ausfallzeiten und Wartungskosten |

Produktintegrität und -konsistenz |

Niedrigere Betriebskosten |

Herausforderungen bei der Staubkontrolle |

|---|

Umgang mit gefährlichem Staub und Dämpfen |

Umgang mit Atemwegsrisiken für Arbeitnehmer |

Einhaltung strenger Umweltvorschriften |

Verbrennungs- und Explosionsgefahren |

Aufrechterhaltung der Produktqualität und -reinheit |

Korrosive Materialien und extreme Temperaturen |

Verschleiß der Ausrüstung |

Hohe Staub- und Rauchentwicklung |

Ausfallzeiten aufgrund von Systemwartungen |

Wichtige Überlegungen zur effektiven Staubkontrolle |

|---|

Effiziente Staub- und Raucherfassung |

Chemische und Hitzebeständigkeit |

Optimiertes Luftstrom- und Druckmanagement |

Fortschrittliche Filtermaterialien |

Routinemäßige Wartung und Inspektionen |

Einhaltung gesetzlicher Vorschriften |

Maßgeschneiderte Filtrationslösungen |

Risikominderung für gefährliche Chemikalien |

Flexible Systemkonfigurationen |

Kontaktieren Sie uns für eine Expertenberatung

Entdecken Sie unsere anderen Dienstleistungen!

Häufig gestellte Fragen

Zu den in der chemischen Verarbeitung eingesetzten Filtersystemen gehören Schlauchfilter zur Trockenstaubabscheidung, Elektrofilter zur Behandlung von Feinstaubemissionen, Nasswäscher zur Kontrolle saurer Gase und Dämpfe sowie Patronenfilter für kleinere Mengen oder zur präzisen Luftqualitätskontrolle. Bei Prozessen mit hohen Temperaturen oder aggressiven Chemikalien kommen auch Heißgasfiltersysteme mit Sintermetallmedien zum Einsatz. Die Auswahl der jeweiligen Lösung erfolgt nach Art der Emissionen, den Prozessbedingungen und den Umweltanforderungen.

Filtersysteme in der chemischen Produktion verbessern die Luftqualität, indem sie Partikel und Schadstoffe, die während der Verarbeitung entstehen, effektiv erfassen und entfernen. Durch die Reduzierung der Emissionen tragen diese Systeme dazu bei, dass die Betriebe Umweltvorschriften und -standards einhalten, ihre Umweltbelastung minimieren und für mehr Sicherheit am Arbeitsplatz sorgen.

Elektrofilter bieten eine hohe Effizienz bei der Feinstaubentfernung und erreichen Wirkungsgrade von bis zu 99%. Dies ist besonders in der chemischen Produktion von Vorteil, da die Rauchgasemissionen häufig Feinstaubpartikel enthalten. Sie können große Gasmengen verarbeiten und arbeiten auch bei hohen Temperaturen effizient. Darüber hinaus weisen Elektrofilter relativ geringe Druckverluste auf, was zu einem geringeren Energieverbrauch im Betrieb führt.