Industrial Baghouse Filter Systems

for Cement & Mineral Plants

Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

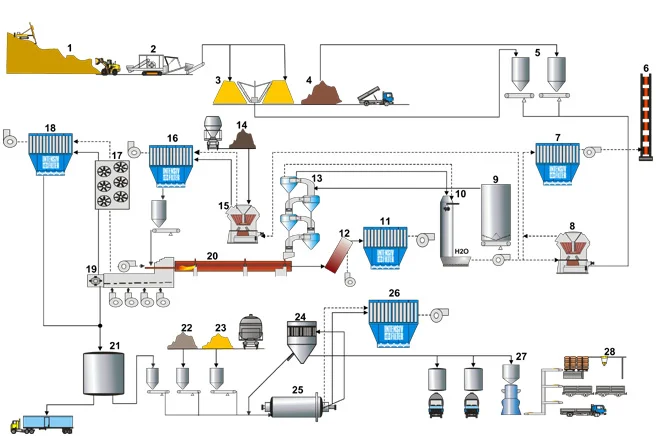

Bag Filters Use Cases in Cement Production Process

Vnější filtr

Rozprašovací sušička

CIP filtr

Externí fluidní lože

Plnicí

- 1. Lom

- 2. Drtič

- 3. Homogenizace surovin

- 4. Kamenivo

- 5. Plnicí silo mlýna

- 6. Hlavní zásobník

- 7. Sáčkový filtr pro vypalovací mlýn

- 8. Vertikální mlýn na suroviny

- 9. Zásobovací silo surovin

- 10. Věž na úpravu plynu

- 11. Kapsový filtr pro alkalický bypass

- 12. Obtok směšovací komory

- 13. Cyklónový předehřívač

- 14. Surové uhlí

- 15. Vertikální mlýn na uhlí

- 16. Kapsový filtr pro brusírnu uhlí

- 17. Trubkový chladič

- 18. Sáčkový filtr pro chladič slínku

- 19. Chladič klinkeru

- 20. Rotační pec

- 21. Slínkové silo

- 22. Sádra

- 23. Minerály

- 24. Separátor

- 25. Cementová dokončovací fréza

- 26. Kapsový filtr pro cementovou dokončovací frézu

- 27. Obalovna

- 28. Paletizační závod

Požadovaná specifikace

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Typická konstrukční data | Pec-/surovina |

|---|---|

Objem plynu | < 1 200 000 |

Teplota plynu | 85 – 110 složených / < 250 přímých |

Druh prachu | CaCO3, CaO |

Zbytkový obsah prachu | < 550 |

Obsah prachu v surovém plynu | < 10 |

Čištění | online / offline |

Filtrační médium | PEA, NX, PPS, PI, GL/PTFE |

Typická konstrukční data | Alkalický bypass |

|---|---|

Objem plynu | < 800 000 |

Teplota plynu | < 250 |

Druh prachu | CaCO3, CaO, alkálie |

Zbytkový obsah prachu | < 25 |

Obsah prachu v surovém plynu | < 10 |

Čištění | offline |

Filtrační médium | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Typická konstrukční data | Uhelný mlýn |

|---|---|

Objem plynu | < 450 000 |

Teplota plynu | 80–110 |

Druh prachu | Uhlí |

Zbytkový obsah prachu | < 250 |

Obsah prachu v surovém plynu | < 10 |

Čištění | online |

Filtrační médium | HRÁŠEK / PAN |

Typická konstrukční data | Trubkový chladič |

|---|---|

Objem plynu | < 1 600 000 |

Teplota plynu v | 250–350 |

Teplota plynu mimo | 120–200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Typická konstrukční data | Clinker chladič |

|---|---|

Objem plynu | < 800 000 |

Teplota plynu | 120–180 |

Druh prachu | Klinker |

Obsah prachu v surovém plynu | 10–30 |

Zbytkový obsah prachu | < 10 |

Čištění | online |

Filtrační médium | PE / NX / PI |

Typická konstrukční data | Cementová dokončovací fréza |

|---|---|

Objem plynu | < 300 000 |

Teplota plynu | 80–110 |

Druh prachu | Cement, struska |

Obsah prachu v surovém plynu | < 350 |

Zbytkový obsah prachu | < 10 |

Čištění | online / offline |

Filtrační médium | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Reguluje prach vznikající při procesech drcení a mletí s vysokou energií, zachycuje jemné částice a zabraňuje jejich úniku do atmosféry.

Snižuje emise z procesů v pecích, kde se suroviny ohřívají, a reguluje prach a další částice ve vzduchu uvolňované během výroby cementu.

Zachycuje prach během přepravy sypkých materiálů, jako je vápenec a slínek, aby se zabránilo uvolňování částic ve skladovacích a přepravních fázích.

Minimalizuje emise prachu v prostorách pro balení a skladování výrobků a zajišťuje, že hotové výrobky jsou baleny a skladovány v prostředí bez kontaminantů.

Regulační prostředí pro kontrolu prachu |

|---|

Normy kvality ovzduší |

Bezpečnost a ochrana zdraví pracovníků |

Prevence požárů a výbuchů |

Ochrana životního prostředí |

Monitorování a hlášení emisí |

Energetická účinnost |

Nakládání s odpady |

Kvalita a konzistence produktů |

Snížené prostoje a náklady na údržbu |

Problémy s kontrolou prachu |

|---|

Vysoká prašnost |

Zdravotní rizika pracovníků |

Soulad s životním prostředím |

Nebezpečí požáru a výbuchu |

Obavy ohledně kvality produktů |

Opotřebení zařízení |

Křížová kontaminace |

Shoda s předpisy o kvalitě ovzduší |

Mikrobiální růst |

Klíčové aspekty pro efektivní kontrolu prachu |

|---|

Zavést účinné systémy pro zachycování prachu |

Správné řízení proudění vzduchu a tlaku |

Řízení teploty a vlhkosti |

Vysoce účinné filtrační systémy |

Pravidelná údržba a inspekce |

Dodržování oborových standardů |

Časté hodnocení systému pro regulaci prachu |

Adaptace specifické pro proces |

Posouzení a zmírňování rizik |

Spojte se s námi pro odbornou konzultaci

Prozkoumejte naše další služby !

Často kladené otázky

V cementářském průmyslu jsou účinná filtrační řešení nezbytná pro kontrolu emisí prachu a zajištění souladu s environmentálními předpisy. Mezi běžně používané filtrační systémy patří látkové filtrační sáčky, které využívají tkaninové filtrační sáčky k zachycení jemných částic z různých procesů, jako jsou pece, mlýny a manipulace s materiálem. Tyto filtry jsou oblíbené pro svou vysokou účinnost při odstraňování pevných částic. Pokročilá filtrační řešení, jako jsou ta, která nabízí společnost Micronics, jsou navíc navržena tak, aby splňovala jedinečné požadavky cementářského průmyslu, zajišťovala soulad s environmentálními předpisy a zvyšovala provozní efektivitu.

Filtrační systémy zlepšují efektivitu výroby cementu tím, že efektivně zachycují prach a pevné částice, snižují opotřebení zařízení a zabraňují ucpávání. To zajišťuje plynulý provoz, minimalizuje prostoje a zvyšuje kvalitu produktu tím, že zabraňuje kontaminaci. Správná kontrola prachu také pomáhá dodržovat předpisy, snižuje riziko vzniku pokut a environmentálních problémů. Účinné filtrační systémy navíc přispívají k úsporám energie optimalizací proudění vzduchu a snižováním tlakových ztrát v systému.

Pokročilé filtrační systémy ve výrobě cementu pomáhají snižovat znečištění ovzduší zachycováním jemných prachových částic a minimalizací emisí škodlivých znečišťujících látek. Zlepšují kvalitu ovzduší, zajišťují dodržování environmentálních předpisů a snižují uhlíkovou stopu odvětví. Zlepšením kontroly prašnosti tyto systémy také přispívají k zdraví a bezpečnosti pracovníků. Kromě toho podporují udržitelnost tím, že umožňují získávání a opětovné použití surovin, snižují množství odpadu a optimalizují energetickou účinnost v procesech výroby cementu.