Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

Bag Filters Use Cases in Cement Production Process

Tashqi filtr

Spray quritgich

CIP filtri

Tashqi suyuq to'shak

To'ldirish

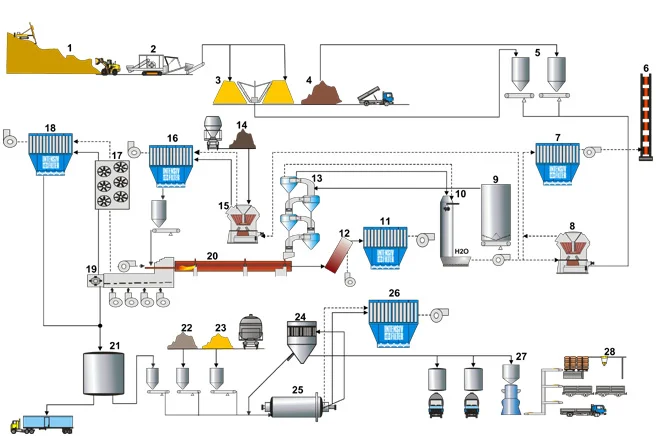

- 1. Karyer

- 2. Maydalagich zavodi

- 3. Xom ashyoni gomogenlashtirish

- 4. Agregatlar

- 5. Xom tegirmon oziqlantiruvchi silos

- 6. Asosiy stack

- 7. Pech-/xom tegirmon uchun sumka filtri

- 8. Vertikal xomashyo tegirmoni

- 9. Xom ashyoni oziqlantiruvchi silos

- 10. Gaz konditsioner minorasi

- 11. Ishqoriy bypass uchun sumka filtri

- 12. Aralashtirish kamerasini aylanib o'tish

- 13. Siklonli oldindan isitgich

- 14. Xom ko'mir

- 15. Vertikal ko'mir maydalagich

- 16. Ko'mirni maydalash zavodi uchun sumka filtri

- 17. Quvurli sovutgich

- 18. Klinker sovutgich uchun sumka filtri

- 19. Klinker sovutgichi

- 20. Aylanadigan pech

- 21. Klinker silos

- 22. Gips

- 23. Foydali qazilmalar

- 24. Separator

- 25. Tsement tayyorlovchi tegirmon

- 26. Tsement pardozlash zavodi uchun sumka filtri

- 27. Qadoqlash zavodi

- 28. Paletizatsiya zavodi

Kerakli spetsifikatsiya

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Oddiy dizayn ma'lumotlari | Pech-/xom tegirmon |

|---|---|

Gaz hajmi | < 1 200 000 |

Gaz harorati | 85 – 110 birikma / < 250 to'g'ridan-to'g'ri |

Chang turi | CaCO3, CaO |

Qoldiq chang tarkibi | < 550 |

Xom gazning chang tarkibi | < 10 |

Tozalash | onlayn / oflayn |

Filtr muhiti | PEA, NX, PPS, PI, GL/PTFE |

Oddiy dizayn ma'lumotlari | Ishqoriy aylanib o'tish |

|---|---|

Gaz hajmi | < 800 000 |

Gaz harorati | < 250 |

Chang turi | CaCO3, CaO, ishqor |

Qoldiq chang tarkibi | < 25 |

Xom gazning chang tarkibi | < 10 |

Tozalash | oflayn |

Filtr muhiti | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Oddiy dizayn ma'lumotlari | Ko'mir tegirmoni |

|---|---|

Gaz hajmi | < 450 000 |

Gaz harorati | 80 - 110 |

Chang turi | Ko'mir |

Qoldiq chang tarkibi | < 250 |

Xom gazning chang tarkibi | < 10 |

Tozalash | onlayn |

Filtr muhiti | PEA / PAN |

Oddiy dizayn ma'lumotlari | Quvurli sovutgich |

|---|---|

Gaz hajmi | < 1 600 000 |

Gaz harorati ichida | 250 - 350 |

Gaz harorati tashqarida | 120 - 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Oddiy dizayn ma'lumotlari | Klinker sovutgich |

|---|---|

Gaz hajmi | < 800 000 |

Gaz harorati | 120 - 180 |

Chang turi | Klinker |

Xom gazning chang tarkibi | 10 - 30 |

Qoldiq chang tarkibi | < 10 |

Tozalash | onlayn |

Filtr muhiti | PE / NX / PI |

Oddiy dizayn ma'lumotlari | Tsement pardozlash zavodi |

|---|---|

Gaz hajmi | < 300 000 |

Gaz harorati | 80 - 110 |

Chang turi | Tsement, shlak |

Xom gazning chang tarkibi | < 350 |

Qoldiq chang tarkibi | < 10 |

Tozalash | onlayn / oflayn |

Filtr muhiti | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Yuqori energiyali maydalash va maydalash jarayonlari natijasida hosil bo'lgan changni nazorat qiladi, mayda zarrachalarni atmosferaga qochib ketishining oldini oladi.

Tsement ishlab chiqarish jarayonida chiqadigan chang va boshqa havodagi zarralarni nazorat qilib, xom ashyo isitiladigan o'choq jarayonlari chiqindilarini kamaytiradi.

Saqlash va tashish bosqichlarida zarrachalar chiqishini oldini olish uchun ohaktosh va klinker kabi quyma materiallarni tashish paytida changni ushlaydi.

Mahsulotlarni qadoqlash va saqlash joylarida chang emissiyasini minimallashtiradi, tayyor mahsulotlarni ifloslantiruvchi moddalarsiz muhitda qadoqlash va saqlashni ta'minlaydi.

Changni nazorat qilish uchun tartibga soluvchi landshaft |

|---|

Havo sifati standartlari |

Ishchilar salomatligi va xavfsizligi |

Yong'in va portlashning oldini olish |

Atrof-muhitni muhofaza qilish |

Emissiya monitoringi va hisoboti |

Energiya samaradorligi |

Chiqindilarni boshqarish |

Mahsulot sifati va izchilligi |

To'xtab qolish muddati va texnik xizmat ko'rsatish xarajatlari kamayadi |

Changni nazorat qilish muammolari |

|---|

Yuqori chang darajalari |

Ishchilar salomatligi uchun xavflar |

Atrof-muhitga muvofiqlik |

Yong'in va portlash xavfi |

Mahsulot sifati bilan bog'liq muammolar |

Uskunaning eskirishi |

O'zaro kontaminatsiya |

Havo sifatiga muvofiqligi |

Mikroblarning o'sishi |

Changni samarali nazorat qilish uchun asosiy fikrlar |

|---|

Samarali changni ushlab turish tizimlarini joriy qiling |

To'g'ri havo oqimi va bosim nazorati |

Harorat va namlikni boshqarish |

Yuqori samarali filtrlash tizimlari |

Muntazam texnik xizmat ko'rsatish va tekshirish |

Sanoat standartlariga rioya qilish |

Changni nazorat qilish tizimini tez-tez baholash |

Jarayonga xos moslashuvlar |

Xatarlarni baholash va kamaytirish |

Mutaxassis maslahati uchun biz bilan bog'laning

Boshqa xizmatlarimiz bilan tanishing!

Tez-tez so'raladigan savollar

Tsement sanoatida chang emissiyasini nazorat qilish va atrof-muhitga rioya qilishni ta'minlash uchun samarali filtrlash echimlari muhim ahamiyatga ega. Odatda ishlatiladigan filtrlash tizimlari orasida pechlar, tegirmonlar va materiallarga ishlov berish kabi turli jarayonlardan nozik zarralarni olish uchun mato filtri qoplaridan foydalanadigan sumka filtrlari kiradi. Ushbu filtrlar zarrachalarni olib tashlashda yuqori samaradorligi uchun afzaldir. Bundan tashqari, Micronics tomonidan taklif qilinganlar kabi ilg'or filtrlash echimlari tsement sanoatining noyob talablarini qondirish, atrof-muhit qoidalariga rioya qilishni ta'minlash va operatsion samaradorlikni oshirish uchun mo'ljallangan.

Filtrlash tizimlari chang va zarrachalarni samarali ushlash, uskunaning eskirishini kamaytirish va blokirovkalarni oldini olish orqali sement ishlab chiqarish samaradorligini oshiradi. Bu uzluksiz ishlashni ta'minlaydi, ishlamay qolish vaqtini kamaytiradi va ifloslanishning oldini olish orqali mahsulot sifatini oshiradi. To'g'ri chang nazorati, shuningdek, me'yoriy hujjatlarga rioya qilishni ta'minlash, jarimalar va atrof-muhit muammolari xavfini kamaytirishga yordam beradi. Bundan tashqari, samarali filtrlash tizimlari havo oqimini optimallashtirish va tizimdagi bosim tushishini kamaytirish orqali energiyani tejashga yordam beradi.

Tsement ishlab chiqarishdagi ilg'or filtrlash tizimlari mayda chang zarralarini ushlash va zararli ifloslantiruvchi moddalar emissiyasini kamaytirish orqali havo ifloslanishini kamaytirishga yordam beradi. Ular havo sifatini yaxshilaydi, atrof-muhitni muhofaza qilish qoidalariga rioya qilishni ta'minlaydi va sanoatdagi uglerod izini kamaytiradi. Ushbu tizimlar chang nazoratini kuchaytirish orqali ishchilar salomatligi va xavfsizligiga ham hissa qo'shadi. Bundan tashqari, ular xom ashyoni qayta tiklash va qayta ishlatish, chiqindilarni kamaytirish va sement ishlab chiqarish jarayonlarida energiya samaradorligini optimallashtirish orqali barqarorlikni qo'llab-quvvatlaydi.