Çimento ve Mineraller Hava ve Toz Filtrasyon Çözümleri

Çimento ve Minerallerde İşlem

Dış filtre

Sprey kurutucu

CIP filtresi

Harici akışkan yatak

Doldurma

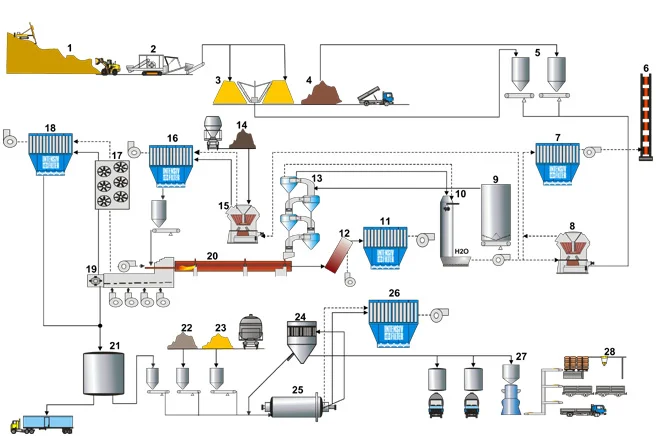

- 1. Taş ocağı

- 2. Kırma tesisi

- 3. Hammadde homojenizasyonu

- 4. Agregalar

- 5. Hammadde değirmeni besleme silosu

- 6. Ana yığın

- 7. Fırın/hamur değirmeni için torba filtresi

- 8. Dikey ham madde değirmeni

- 9. Hammadde besleme silosu

- 10. Gaz şartlandırma kulesi

- 11. Alkali bypass için torba filtre

- 12. Baypas karıştırma odası

- 13. Siklon ön ısıtıcı

- 14. Ham kömür

- 15. Dikey kömür öğütme değirmeni

- 16. Kömür öğütme tesisi için torba filtre

- 17. Borulu soğutucu

- 18. Klinker soğutucu için torba filtre

- 19. Klinker soğutucu

- 20. Döner fırın

- 21. Klinker silosu

- 22. Alçıtaşı

- 23. Mineraller

- 24. Ayırıcı

- 25. Çimento bitirme değirmeni

- 26. Çimento son işlem değirmeni için torba filtresi

- 27. Paketleme tesisi

- 28. Paletleme tesisi

Gerekli Özellikler

Filtre Başlığı PJM

Filtre Başlığı PJM

Tipik tasarım verileri | Fırın-/ham değirmen |

|---|---|

Gaz hacmi | < 1.200.000 |

Gaz sıcaklığı | 85 – 110 bileşik / < 250 doğrudan |

Toz türü | CaCO3, CaO |

Kalan toz içeriği | < 550 |

Ham gaz tozu içeriği | < 10 |

Temizlik | çevrimiçi / çevrimdışı |

Filtre ortamı | Bezelye, NX, PPS, Pİ, GL/PTFE |

Tipik tasarım verileri | Alkali baypas |

|---|---|

Gaz hacmi | < 800.000 |

Gaz sıcaklığı | < 250 |

Toz türü | CaCO3, CaO, Alkali |

Kalan toz içeriği | < 25 |

Ham gaz tozu içeriği | < 10 |

Temizlik | çevrimdışı |

Filtre ortamı | PTFE-PI / GL-PTFE |

Filtre başlığı IF JCC / IF JC

Borulu soğutucu IF TC

Tipik tasarım verileri | Kömür değirmeni |

|---|---|

Gaz hacmi | < 450.000 |

Gaz sıcaklığı | 80 – 110 |

Toz türü | Kömür |

Kalan toz içeriği | < 250 |

Ham gaz tozu içeriği | < 10 |

Temizlik | çevrimiçi |

Filtre ortamı | BEZELYE / TAVASI |

Tipik tasarım verileri | Borulu soğutucu |

|---|---|

Gaz hacmi | < 1.600.000 |

Gaz sıcaklığı | 250 – 350 |

Gaz sıcaklığı dışarı | 120 – 200 |

Filtre başlığı PJM

Filtre başlığı PJM

Tipik tasarım verileri | Klinker soğutucu |

|---|---|

Gaz hacmi | < 800.000 |

Gaz sıcaklığı | 120 – 180 |

Toz türü | Klinker |

Ham gaz tozu içeriği | 10 – 30 |

Kalan toz içeriği | < 10 |

Temizlik | çevrimiçi |

Filtre ortamı | PE / NX / Pİ |

Tipik tasarım verileri | Çimento bitirme değirmeni |

|---|---|

Gaz hacmi | < 300.000 |

Gaz sıcaklığı | 80 – 110 |

Toz türü | Çimento, cüruf |

Ham gaz tozu içeriği | < 350 |

Kalan toz içeriği | < 10 |

Temizlik | çevrimiçi / çevrimdışı |

Filtre ortamı | Beden Eğitimi / Bezelye |

Çimento ve Mineraller için Ürünlerimizin Uygulamaları

Yüksek enerjili kırma ve öğütme işlemlerinden kaynaklanan tozu kontrol altına alır, ince partikül maddelerin atmosfere kaçmasını önler.

Çimento üretimi sırasında açığa çıkan toz ve diğer havaya karışan partikülleri kontrol ederek, hammaddelerin ısıtıldığı fırın proseslerinden kaynaklanan emisyonları azaltır.

Kireç taşı ve klinker gibi dökme malzemelerin taşınması sırasında oluşan tozu yakalayarak depolama ve taşıma aşamalarında partikül salınımını önler.

Ürün paketleme ve depolama alanlarında toz emisyonunu en aza indirerek, bitmiş ürünlerin kirletici maddelerden arındırılmış bir ortamda paketlenmesini ve depolanmasını sağlar.

Toz Kontrolü için Düzenleyici Manzara |

|---|

Hava Kalitesi Standartları |

İşçi Sağlığı ve Güvenliği |

Yangın ve Patlama Önleme |

Çevre Koruma |

Emisyon İzleme ve Raporlama |

Enerji Verimliliği |

Atık Yönetimi |

Ürün Kalitesi ve Tutarlılığı |

Azaltılmış Duruş Süresi ve Bakım Maliyetleri |

Toz Kontrol Zorlukları |

|---|

Yüksek Toz Seviyeleri |

İşçi Sağlığı Riskleri |

Çevresel Uyumluluk |

Yangın ve Patlama Tehlikeleri |

Ürün Kalitesi Endişeleri |

Ekipman Aşınması ve Yıpranması |

Çapraz Bulaşma |

Hava Kalitesi Uyumluluğu |

Mikrobiyal Büyüme |

Etkili Toz Kontrolü İçin Temel Hususlar |

|---|

Etkili Toz Yakalama Sistemlerini Uygulayın |

Uygun Hava Akışı ve Basınç Kontrolü |

Sıcaklık ve Nem Yönetimi |

Yüksek Verimli Filtrasyon Sistemleri |

Düzenli Bakım ve Muayene |

Endüstri Standartlarına Uygunluk |

Toz Kontrol Sisteminin Sık Değerlendirilmesi |

Süreç Spesifik Uyarlamalar |

Risk Değerlendirmesi ve Azaltma |

Uzman Danışmanlığı için bizimle iletişime geçin

Diğer Hizmetlerimizi Keşfedin!

Sıkça Sorulan Sorular

Çimento endüstrisinde, toz emisyonlarını kontrol altına almak ve çevre uyumluluğunu sağlamak için etkili filtrasyon çözümleri olmazsa olmazdır. Yaygın olarak kullanılan filtrasyon sistemleri arasında, fırınlar, değirmenler ve malzeme taşıma gibi çeşitli proseslerden gelen ince partikülleri yakalamak için bez filtre torbaları kullanan torba filtreler bulunur. Bu filtreler, partikül maddeyi gidermedeki yüksek verimlilikleri nedeniyle tercih edilir. Ayrıca, Micronics tarafından sunulan gelişmiş filtrasyon çözümleri, çimento endüstrisinin kendine özgü taleplerini karşılamak, çevre düzenlemelerine uyumu sağlamak ve operasyonel verimliliği artırmak üzere tasarlanmıştır.

Filtreleme sistemleri, toz ve partikül maddeleri etkili bir şekilde yakalayarak, ekipman aşınmasını azaltarak ve tıkanmaları önleyerek çimento üretiminde verimliliği artırır. Bu, sorunsuz bir çalışma sağlar, duruş sürelerini en aza indirir ve kontaminasyonu önleyerek ürün kalitesini artırır. Doğru toz kontrolü ayrıca yasal düzenlemelere uygunluğun sağlanmasına yardımcı olarak para cezası ve çevre sorunları riskini azaltır. Ayrıca, verimli filtreleme sistemleri hava akışını optimize ederek ve sistemdeki basınç düşüşlerini azaltarak enerji tasarrufuna katkıda bulunur.

Çimento üretimindeki gelişmiş filtreleme sistemleri, ince toz parçacıklarını yakalayarak ve zararlı kirletici emisyonlarını en aza indirerek hava kirliliğini azaltmaya yardımcı olur. Hava kalitesini iyileştirerek çevre düzenlemelerine uyumu sağlar ve sektörün karbon ayak izini azaltır. Bu sistemler, toz kontrolünü iyileştirerek işçi sağlığı ve güvenliğine de katkıda bulunur. Ayrıca, hammaddelerin geri kazanılmasını ve yeniden kullanılmasını sağlayarak, atıkları azaltarak ve çimento üretim süreçlerinde enerji verimliliğini optimize ederek sürdürülebilirliği destekler.