Industrial Baghouse Filter Systems

for Cement & Mineral Plants

Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

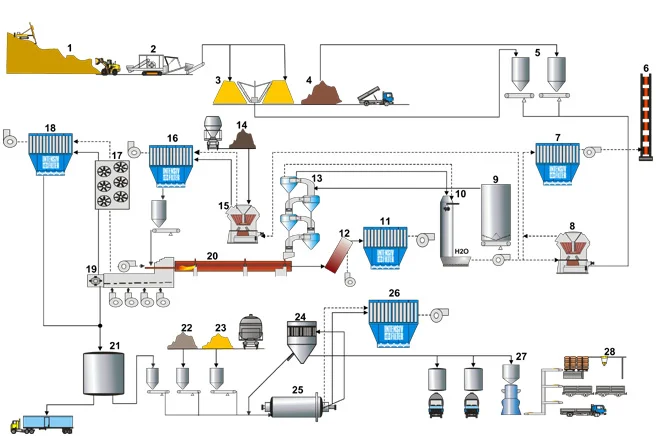

Bag Filters Use Cases in Cement Production Process

Zunanji filter

Sušilnik z razpršilom

CIP filter

Zunanja fluidizirana postelja

Polnjenje

- 1. Kamnolom

- 2. Drobilnik

- 3. Homogenizacija surovin

- 4. Agregati

- 5. Silos za hranjenje surovin

- 6. Glavni sklad

- 7. Vrečasti filter za peč/mlin za surovine

- 8. Vertikalni mlin za surovine

- 9. Silos za dovajanje surovin

- 10. Stolp za kondicioniranje plina

- 11. Vrečasti filter za alkalni bypass

- 12. Obvodna mešalna komora

- 13. Ciklonski predgrelnik

- 14. Surovi premog

- 15. Vertikalni mlin za mletje premoga

- 16. Vrečasti filter za mlinišče premoga

- 17. Cevni hladilnik

- 18. Vrečasti filter za hladilnik klinkerja

- 19. Hladilnik klinkerja

- 20. Rotacijska peč

- 21. Silos za klinker

- 22. Mavec

- 23. Minerali

- 24. Ločilo

- 25. Mlin za končno obdelavo cementa

- 26. Vrečasti filter za cementni mlin

- 27. Pakirni obrat

- 28. Obrat za paletiranje

Zahtevana specifikacija

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Tipični konstrukcijski podatki | Peč/mlin za surovine |

|---|---|

Prostornina plina | < 1.200.000 |

Temperatura plina | 85 – 110 sestavljeno / < 250 neposredno |

Vrsta prahu | CaCO3, CaO |

Vsebnost preostalega prahu | < 550 |

Vsebnost prahu v surovem plinu | < 10 |

Čiščenje | na spletu / brez povezave |

Filtrirni medij | PEA, NX, PPS, PI, GL/PTFE |

Tipični konstrukcijski podatki | Alkalijski obvod |

|---|---|

Prostornina plina | < 800.000 |

Temperatura plina | < 250 |

Vrsta prahu | CaCO3, CaO, alkalije |

Vsebnost preostalega prahu | < 25 |

Vsebnost prahu v surovem plinu | < 10 |

Čiščenje | brez povezave |

Filtrirni medij | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Tipični konstrukcijski podatki | Mlin za premog |

|---|---|

Prostornina plina | < 450.000 |

Temperatura plina | 80 – 110 |

Vrsta prahu | Premog |

Vsebnost preostalega prahu | < 250 |

Vsebnost prahu v surovem plinu | < 10 |

Čiščenje | na spletu |

Filtrirni medij | GRAH / PONEV |

Tipični konstrukcijski podatki | Cevni hladilnik |

|---|---|

Prostornina plina | < 1.600.000 |

Temperatura plina v | 250 – 350 |

Temperatura plina zunaj | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Tipični konstrukcijski podatki | Hladilnik klinkerja |

|---|---|

Prostornina plina | < 800.000 |

Temperatura plina | 120 – 180 |

Vrsta prahu | Klinker |

Vsebnost prahu v surovem plinu | 10 – 30 |

Vsebnost preostalega prahu | < 10 |

Čiščenje | na spletu |

Filtrirni medij | PE/NX/PI |

Tipični konstrukcijski podatki | Končni mlin za cement |

|---|---|

Prostornina plina | < 300.000 |

Temperatura plina | 80 – 110 |

Vrsta prahu | Cement, žlindra |

Vsebnost prahu v surovem plinu | < 350 |

Vsebnost preostalega prahu | < 10 |

Čiščenje | na spletu / brez povezave |

Filtrirni medij | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Nadzira prah, ki nastane pri visokoenergijskih procesih drobljenja in mletja, ter zajema fine delce, da prepreči njihov uhajanje v ozračje.

Zmanjšuje emisije iz procesov v pečeh, kjer se surovine segrevajo, s čimer nadzoruje prah in druge delce v zraku, ki se sproščajo med proizvodnjo cementa.

Zajame prah med prevozom razsutih materialov, kot sta apnenec in klinker, da prepreči sproščanje delcev med skladiščenjem in transportom.

Zmanjšuje emisije prahu v prostorih za pakiranje in skladiščenje izdelkov, s čimer zagotavlja, da so končni izdelki pakirani in shranjeni v okolju brez onesnaževalcev.

Regulativna krajina za nadzor prahu |

|---|

Standardi kakovosti zraka |

Zdravje in varnost delavcev |

Preprečevanje požarov in eksplozij |

Varstvo okolja |

Spremljanje in poročanje o emisijah |

Energijska učinkovitost |

Ravnanje z odpadki |

Kakovost in doslednost izdelkov |

Zmanjšani stroški izpadov in vzdrževanja |

Izzivi nadzora prahu |

|---|

Visoka raven prahu |

Tveganja za zdravje delavcev |

Okoljska skladnost |

Nevarnosti požara in eksplozije |

Pomisleki glede kakovosti izdelkov |

Obraba opreme |

Navzkrižna kontaminacija |

Skladnost s predpisi o kakovosti zraka |

Rast mikrobov |

Ključni dejavniki za učinkovito zatiranje prahu |

|---|

Uvedite učinkovite sisteme za zajemanje prahu |

Pravilen nadzor pretoka zraka in tlaka |

Upravljanje temperature in vlage |

Visoko učinkoviti filtracijski sistemi |

Redno vzdrževanje in pregled |

Spoštovanje industrijskih standardov |

Pogosto ocenjevanje sistema za nadzor prahu |

Prilagoditve, specifične za proces |

Ocena in zmanjševanje tveganja |

Povežite se z nami za strokovni posvet

Raziščite naše druge storitve!

Pogosto zastavljena vprašanja

V cementni industriji so učinkovite filtracijske rešitve bistvenega pomena za nadzor emisij prahu in zagotavljanje okoljske skladnosti. Pogosto uporabljeni filtracijski sistemi vključujejo vrečaste filtre, ki uporabljajo tkaninske filtrirne vrečke za zajemanje drobnih delcev iz različnih procesov, kot so peči, mlini in ravnanje z materiali. Ti filtri so priljubljeni zaradi svoje visoke učinkovitosti pri odstranjevanju trdnih delcev. Poleg tega so napredne filtracijske rešitve, kot so tiste, ki jih ponuja Micronics, zasnovane tako, da izpolnjujejo edinstvene zahteve cementne industrije, zagotavljajo skladnost z okoljskimi predpisi in izboljšujejo operativno učinkovitost.

Filtracijski sistemi izboljšujejo učinkovitost proizvodnje cementa z učinkovitim zajemanjem prahu in delcev, zmanjšanjem obrabe opreme in preprečevanjem blokad. To zagotavlja nemoteno delovanje, zmanjšuje izpade in izboljšuje kakovost izdelkov s preprečevanjem kontaminacije. Ustrezen nadzor prahu pomaga tudi pri ohranjanju skladnosti s predpisi, kar zmanjšuje tveganje za globe in okoljske težave. Poleg tega učinkoviti filtracijski sistemi prispevajo k prihranku energije z optimizacijo pretoka zraka in zmanjšanjem padcev tlaka v sistemu.

Napredni filtracijski sistemi v proizvodnji cementa pomagajo zmanjšati onesnaženost zraka z zajemanjem drobnih prašnih delcev in zmanjševanjem emisij škodljivih onesnaževal. Izboljšujejo kakovost zraka, zagotavljajo skladnost z okoljskimi predpisi in zmanjšujejo ogljični odtis industrije. Z izboljšanjem nadzora prahu ti sistemi prispevajo tudi k zdravju in varnosti delavcev. Poleg tega podpirajo trajnost, saj omogočajo predelavo in ponovno uporabo surovin, zmanjšujejo količino odpadkov in optimizirajo energetsko učinkovitost v procesih proizvodnje cementa.