Industrial Baghouse Filter Systems

for Cement & Mineral Plants

Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

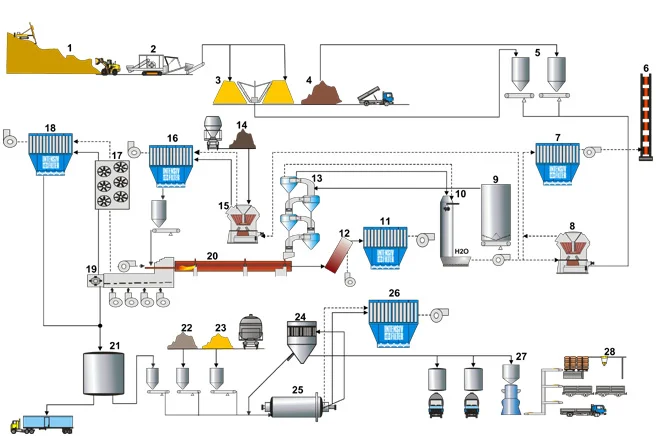

Bag Filters Use Cases in Cement Production Process

Filtr zewnętrzny

Suszarka rozpyłowa

Filtr CIP

Zewnętrzne złoże fluidalne

Pożywny

- 1. Kamieniołom

- 2. Zakład kruszenia

- 3. Homogenizacja surowca

- 4. Kruszywa

- 5. Silos zasilający młyn surowcowy

- 6. Główny stos

- 7. Filtr workowy do pieca/młyna surowcowego

- 8. Młyn do surowca pionowy

- 9. Silos do podawania surowca

- 10. Wieża do kondycjonowania gazu

- 11. Filtr workowy do obejścia alkalicznego

- 12. Obejście komory mieszającej

- 13. Podgrzewacz cyklonowy

- 14. Węgiel surowy

- 15. Młyn pionowy do mielenia węgla

- 16. Filtr workowy do zakładu przemiału węgla

- 17. Chłodnica rurowa

- 18. Filtr workowy do chłodnika klinkieru

- 19. Chłodnica klinkieru

- 20. Piec obrotowy

- 21. Silos klinkierowy

- 22. Gips

- 23. Minerały

- 24. Separator

- 25. Walcownia cementu

- 26. Filtr workowy do młyna cementowego

- 27. Zakład pakujący

- 28. Zakład paletyzacji

Wymagana specyfikacja

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Typowe dane projektowe | Piec/młyn surowcowy |

|---|---|

Objętość gazu | < 1 200 000 |

Temperatura gazu | 85 – 110 związek / < 250 bezpośredni |

Rodzaj pyłu | CaCO3, CaO |

Zawartość pyłu resztkowego | < 550 |

Zawartość pyłu w gazie surowym | < 10 |

Czyszczenie | online/offline |

Medium filtracyjne | PEA, NX, PPS, PI, GL/PTFE |

Typowe dane projektowe | Ominięcie alkaliczne |

|---|---|

Objętość gazu | < 800 000 |

Temperatura gazu | < 250 |

Rodzaj pyłu | CaCO3, CaO, Alkali |

Zawartość pyłu resztkowego | < 25 |

Zawartość pyłu w gazie surowym | < 10 |

Czyszczenie | nieaktywny |

Medium filtracyjne | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Typowe dane projektowe | Młyn węglowy |

|---|---|

Objętość gazu | < 450 000 |

Temperatura gazu | 80 – 110 |

Rodzaj pyłu | Węgiel |

Zawartość pyłu resztkowego | < 250 |

Zawartość pyłu w gazie surowym | < 10 |

Czyszczenie | w sieci |

Medium filtracyjne | GROSZEK / PAN |

Typowe dane projektowe | Chłodnica rurowa |

|---|---|

Objętość gazu | < 1 600 000 |

Temperatura gazu w | 250 – 350 |

Temperatura gazu na wyjściu | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Typowe dane projektowe | Chłodnica klinkieru |

|---|---|

Objętość gazu | < 800 000 |

Temperatura gazu | 120 – 180 |

Rodzaj pyłu | Klinkier |

Zawartość pyłu w gazie surowym | 10 – 30 |

Zawartość pyłu resztkowego | < 10 |

Czyszczenie | w sieci |

Medium filtracyjne | PE / NX / PI |

Typowe dane projektowe | Młyn wykańczający cementu |

|---|---|

Objętość gazu | < 300 000 |

Temperatura gazu | 80 – 110 |

Rodzaj pyłu | Cement, żużel |

Zawartość pyłu w gazie surowym | < 350 |

Zawartość pyłu resztkowego | < 10 |

Czyszczenie | online/offline |

Medium filtracyjne | WF / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Ogranicza ilość pyłu powstającego w wyniku procesów kruszenia i mielenia wymagających dużej energii, wychwytując drobne cząstki stałe i zapobiegając ich przedostawaniu się do atmosfery.

Zmniejsza emisje pochodzące z procesów w piecach, w których podgrzewane są surowce, kontrolując ilość pyłu i innych unoszących się w powietrzu cząsteczek uwalnianych podczas produkcji cementu.

Wychwytuje pył powstający w trakcie transportu materiałów sypkich, np. wapienia i klinkieru, zapobiegając uwalnianiu się cząstek podczas magazynowania i transportu.

Minimalizuje emisję pyłu w miejscach pakowania i magazynowania produktów, gwarantując, że gotowe produkty są pakowane i przechowywane w środowisku wolnym od zanieczyszczeń.

Krajobraz regulacyjny w zakresie kontroli zapylenia |

|---|

Normy jakości powietrza |

Zdrowie i bezpieczeństwo pracowników |

Zapobieganie pożarom i wybuchom |

Ochrona środowiska |

Monitorowanie i raportowanie emisji |

Efektywność energetyczna |

Gospodarka odpadami |

Jakość i spójność produktu |

Zmniejszone przestoje i koszty konserwacji |

Wyzwania związane z kontrolą zapylenia |

|---|

Wysoki poziom pyłu |

Zagrożenia dla zdrowia pracowników |

Zgodność z przepisami ochrony środowiska |

Zagrożenia pożarem i wybuchem |

Obawy dotyczące jakości produktu |

Zużycie sprzętu |

Zakażenie krzyżowe |

Zgodność z normami jakości powietrza |

Wzrost mikroorganizmów |

Kluczowe kwestie dotyczące skutecznej kontroli zapylenia |

|---|

Wdrażanie efektywnych systemów wychwytywania pyłu |

Prawidłowy przepływ powietrza i kontrola ciśnienia |

Zarządzanie temperaturą i wilgocią |

Wysokowydajne systemy filtracji |

Regularna konserwacja i przeglądy |

Przestrzeganie standardów branżowych |

Częsta ocena systemu kontroli zapylenia |

Adaptacje specyficzne dla procesu |

Ocena i ograniczanie ryzyka |

Skontaktuj się z nami, aby uzyskać fachową konsultację

Poznaj nasze inne usługi!

Często zadawane pytania

W przemyśle cementowym skuteczne rozwiązania filtracyjne są niezbędne do kontrolowania emisji pyłu i zapewnienia zgodności z przepisami ochrony środowiska. Powszechnie stosowane systemy filtracji obejmują filtry workowe, które wykorzystują tkaninowe worki filtracyjne do wychwytywania drobnych cząstek z różnych procesów, takich jak piece, młyny i przeładunek materiałów. Filtry te są cenione ze względu na wysoką skuteczność w usuwaniu cząstek stałych. Ponadto, zaawansowane rozwiązania filtracyjne, takie jak te oferowane przez Micronics, zostały zaprojektowane tak, aby sprostać specyficznym potrzebom przemysłu cementowego, zapewniając zgodność z przepisami ochrony środowiska i zwiększając wydajność operacyjną.

Systemy filtracji zwiększają wydajność produkcji cementu poprzez skuteczne wychwytywanie pyłu i cząstek stałych, zmniejszając zużycie urządzeń i zapobiegając zatykaniu. Zapewnia to płynną pracę, minimalizuje przestoje i poprawia jakość produktu poprzez zapobieganie zanieczyszczeniom. Prawidłowa kontrola zapylenia pomaga również zachować zgodność z przepisami, zmniejszając ryzyko kar pieniężnych i problemów środowiskowych. Ponadto, wydajne systemy filtracji przyczyniają się do oszczędności energii poprzez optymalizację przepływu powietrza i redukcję spadków ciśnienia w systemie.

Zaawansowane systemy filtracji w produkcji cementu pomagają zmniejszyć zanieczyszczenie powietrza poprzez wychwytywanie drobnych cząstek pyłu i minimalizację emisji szkodliwych substancji. Poprawiają jakość powietrza, zapewniając zgodność z przepisami ochrony środowiska i zmniejszając ślad węglowy przemysłu. Poprzez poprawę kontroli zapylenia, systemy te przyczyniają się również do poprawy zdrowia i bezpieczeństwa pracowników. Ponadto wspierają zrównoważony rozwój, umożliwiając odzysk i ponowne wykorzystanie surowców, redukcję odpadów i optymalizację efektywności energetycznej w procesach produkcji cementu.