Kantoren

HOOFDKANTOOR

Duitsland

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Duitsland/Duitsland - +49 20534200990

REGIONAAL KANTOOR

Groot-Brittannië

- Intensief filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Groot-Brittannië - +44 1922 628893

REGIONAAL KANTOOR

Verenigde Arabische Emiraten

- Intensieve filter Himenviro Technologies FZE – LLC

Businesscentrum, Sharjah Publishing City Free Zone, Sharjah, VAE - +971-556074697

REGIONAAL KANTOOR

Indië

- Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAAL KANTOOR

Indië

- Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAAL KANTOOR

Indië

- Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Lucht- en stoffiltratieoplossingen voor de glasindustrie

De glasindustrie wordt gekenmerkt door hoge temperaturen, het gebruik van grondstoffen die fijnstof genereren en de productie van vluchtige dampen. Deze factoren vormen aanzienlijke risico's voor de gezondheid van werknemers, de naleving van milieuvoorschriften en de productkwaliteit. Onze lucht- en stoffiltersystemen zijn speciaal ontworpen voor de glasindustrie en zorgen voor een efficiënte afvang van zwevende deeltjes, dampen en gassen in kritieke productiefasen. Onze oplossingen helpen fabrikanten te voldoen aan de wettelijke normen, werknemers te beschermen en ervoor te zorgen dat producten hun hoge kwaliteit behouden zonder contaminatie.

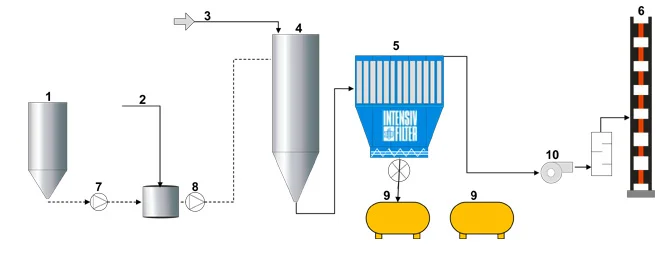

Stoffiltratieproces in de glasindustrie

Filter voor glasoven

- 1. NaOH-tank

- 2. Water

- 3. Heet gas uit de glazen bak

- 4. Blusreactor

- 5. Filter voor glasoven

- 6. Schoorsteen

- 7. Doseerpomp

- 8. Bluspomp

- 9. Transportcontainer

- 10. Geïnduceerde tocht

Vereiste specificaties

Typische ontwerpgegevens | Residuverbrandingsovens |

|---|---|

Gasvolume | 38,000 |

Gastemperatuur | 180 – 200 |

Soort stof | Natriumsulfaat, soda, borax, kwarts |

Ruw gasstofgehalte | 10 – 25 |

Reststofgehalte | < 10 |

Schoonmaak | offline |

Filtermedium | Polyimide |

Sorptiemiddel | Natriumhydroxide |

Toepassingen voor stofbeheersing in de glasindustrie

Filtert zwevend stof tijdens de verwerking en opslag van grondstoffen zoals silica, soda en kalksteen, zodat het stof zich niet naar andere delen van de faciliteit verspreidt.

Houdt de luchtvervuiling en het zwevende stof dat tijdens het smeltproces ontstaat onder controle en zorgt voor schone lucht rondom de ovenruimtes met hoge temperaturen.

Vermindert stof en fijnstof dat ontstaat tijdens het vormen en modelleren van glasproducten. Zo wordt verontreiniging voorkomen en wordt de productintegriteit verbeterd.

Regelgevingslandschap voor stofbeheersing |

|---|

Naleving van luchtkwaliteitsnormen |

Naleving van de gezondheids- en veiligheidsvoorschriften voor werknemers |

Preventie van brand- en explosiegevaar |

Naleving van milieubescherming |

Realtime emissiemonitoring |

Hitte- en corrosiebestendigheid |

Minder uitvaltijd en onderhoudskosten |

Kwaliteit en productconsistentie |

Operationele kostenbesparingen |

Uitdagingen op het gebied van stofbeheersing in de glasindustrie |

|---|

Hoge stofontwikkeling |

Hitte- en corrosieve omgevingen |

Veiligheidsrisico's voor werknemers |

Verbrandings- en explosiegevaren |

Behoud van productkwaliteit en zuiverheid |

Productverontreiniging |

Slijtage van apparatuur |

Dampen en gasvormige emissies |

Kruisbesmetting |

Belangrijke overwegingen voor effectieve stofbeheersing |

|---|

Efficiënte stof- en dampafvang |

Chemische en hittebestendigheid |

Geoptimaliseerd luchtstroom- en drukbeheer |

Geavanceerde filtratiematerialen |

Routineonderhoud en inspecties |

Naleving van regelgevende normen |

Op maat gemaakte filtratieoplossingen |

Risicobeperking voor gevaarlijke chemicaliën |

Flexibele systeemconfiguraties |

Neem contact met ons op voor deskundig advies

Ontdek onze andere diensten!

Veelgestelde vragen

Bij de glasproductie komen aanzienlijke hoeveelheden fijn, schurend stof vrij – met name silicarijke deeltjes – tijdens de verwerking van grondstoffen zoals zand, soda, kalksteen en glasscherven. Deze deeltjes vormen ernstige gezondheidsrisico's, zoals silicose en ademhalingsproblemen. Effectieve filtratie waarborgt de veiligheid van werknemers, voorkomt slijtage van apparatuur, behoudt de productzuiverheid en maakt naleving van milieuvoorschriften mogelijk die een afvangrendement tot 99,9% vereisen.

Stof afkomstig van het breken en verwerken van glas is extreem schurend en chemisch inert, terwijl het silicagehalte het zelfs bij microscopische deeltjes kankerverwekkend maakt. Glaspuinstof is zeer onregelmatig en schurend, wat de slijtage van het filtermateriaal versnelt en een robuust inlaatontwerp, robuuste trechters en luchtstroombeheer vereist om snelle degradatie van filterzakken of -patronen te voorkomen.

Glasfabrieken gebruiken doorgaans stoffen filters (stoffilters) om een zeer efficiënte deeltjesbeheersing te bereiken. Bij toepassingen met hoge temperaturen of een hoge abrasiviteit van silica kunnen duurzame stoffiltersystemen met slijtvaste media of cartridge-type collectoren de voorkeur hebben. Voor processen die zure gassen of vluchtige emissies genereren, kunnen aanvullende natte scrubbers nodig zijn.