Industrial Baghouse Filter Systems

for Cement & Mineral Plants

Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

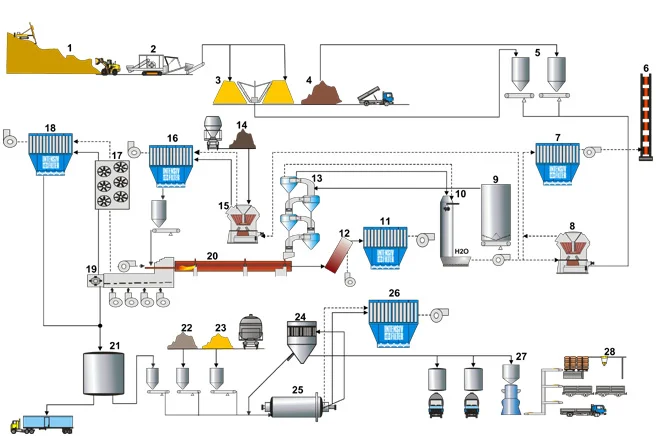

Bag Filters Use Cases in Cement Production Process

Buitenfilter

Sproeidroger

CIP-filter

Extern wervelbed

Vulling

- 1. Steengroeve

- 2. Brekerinstallatie

- 3. Homogenisatie van grondstoffen

- 4. Aggregaten

- 5. Ruwe molen toevoer silo

- 6. Hoofdstapel

- 7. Zakfilter voor oven-/ruwe molen

- 8. Verticale ruwmolen

- 9. Grondstoftoevoersilo

- 10. Gasconditioneringstoren

- 11. Zakfilter voor alkali-bypass

- 12. Bypass-mengkamer

- 13. Cycloonvoorverwarmer

- 14. Ruwe steenkool

- 15. Verticale kolenmaalmolen

- 16. Zakfilter voor kolenmaalinstallatie

- 17. Buisvormige koeler

- 18. Zakfilter voor klinkerkoeler

- 19. Klinkerkoeler

- 20. Draaioven

- 21. Klinkersilo

- 22. Gips

- 23. Mineralen

- 24. Scheidingsteken

- 25. Cementafwerkingsmolen

- 26. Zakfilter voor cementafwerkingsmolen

- 27. Verpakkingsfabriek

- 28. Palletiseerinstallatie

Vereiste specificatie

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Typische ontwerpgegevens | Oven-/ruwe molen |

|---|---|

Gasvolume | < 1.200.000 |

Gastemperatuur | 85 – 110 samengesteld / < 250 direct |

Soort stof | CaCO3, CaO |

Reststofgehalte | < 550 |

Ruw gasstofgehalte | < 10 |

Schoonmaak | online / offline |

Filtermedium | PEA, NX, PPS, PI, GL/PTFE |

Typische ontwerpgegevens | Alkali-bypass |

|---|---|

Gasvolume | < 800.000 |

Gastemperatuur | < 250 |

Soort stof | CaCO3, CaO, Alkali |

Reststofgehalte | < 25 |

Ruw gasstofgehalte | < 10 |

Schoonmaak | offline |

Filtermedium | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Typische ontwerpgegevens | Kolenmolen |

|---|---|

Gasvolume | < 450.000 |

Gastemperatuur | 80 – 110 |

Soort stof | Kolen |

Reststofgehalte | < 250 |

Ruw gasstofgehalte | < 10 |

Schoonmaak | online |

Filtermedium | PEA / PAN |

Typische ontwerpgegevens | Buisvormige koeler |

|---|---|

Gasvolume | < 1.600.000 |

Gastemperatuur in | 250 – 350 |

Gastemperatuur uit | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Typische ontwerpgegevens | Klinkerkoeler |

|---|---|

Gasvolume | < 800.000 |

Gastemperatuur | 120 – 180 |

Soort stof | Klinker |

Ruw gasstofgehalte | 10 – 30 |

Reststofgehalte | < 10 |

Schoonmaak | online |

Filtermedium | PE / NX / PI |

Typische ontwerpgegevens | Cementafwerkingsmolen |

|---|---|

Gasvolume | < 300.000 |

Gastemperatuur | 80 – 110 |

Soort stof | Cement, slakken |

Ruw gasstofgehalte | < 350 |

Reststofgehalte | < 10 |

Schoonmaak | online / offline |

Filtermedium | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Beheerst het stof dat ontstaat bij energierijke breek- en maalprocessen en voorkomt dat fijne deeltjes in de atmosfeer terechtkomen.

Vermindert de uitstoot van ovenprocessen waarbij grondstoffen worden verhit en reguleert stof en andere zwevende deeltjes die vrijkomen tijdens de cementproductie.

Vangt stof op tijdens het transport van stortgoederen, zoals kalksteen en klinker, om te voorkomen dat er deeltjes vrijkomen tijdens de opslag en het transport.

Minimaliseert stofemissies in productverpakkings- en opslagruimtes en zorgt ervoor dat eindproducten worden verpakt en opgeslagen in een omgeving zonder verontreinigingen.

Regelgevingslandschap voor stofbeheersing |

|---|

Luchtkwaliteitsnormen |

Gezondheid en veiligheid van werknemers |

Brand- en explosiepreventie |

Milieubescherming |

Emissiemonitoring en rapportage |

Energie-efficiëntie |

Afvalbeheer |

Productkwaliteit en consistentie |

Minder uitvaltijd en onderhoudskosten |

Uitdagingen op het gebied van stofbeheersing |

|---|

Hoge stofniveaus |

Gezondheidsrisico's voor werknemers |

Milieunaleving |

Brand- en explosiegevaren |

Zorgen over productkwaliteit |

Slijtage van apparatuur |

Kruisbesmetting |

Naleving van de luchtkwaliteit |

Microbiële groei |

Belangrijke overwegingen voor effectieve stofbeheersing |

|---|

Implementeer effectieve stofafvangsystemen |

Juiste luchtstroom- en drukregeling |

Temperatuur- en vochtbeheer |

Hoog-efficiënte filtratiesystemen |

Regelmatig onderhoud en inspectie |

Naleving van industrienormen |

Regelmatige beoordeling van het stofbeheersingssysteem |

Processpecifieke aanpassingen |

Risicobeoordeling en -beperking |

Neem contact met ons op voor deskundig advies

Ontdek onze andere diensten!

Veelgestelde vragen

In de cementindustrie zijn effectieve filtratieoplossingen essentieel voor het beheersen van stofemissies en het waarborgen van de naleving van milieuvoorschriften. Veelgebruikte filtratiesystemen zijn doekenfilters, die gebruikmaken van stoffen filterzakken om fijne deeltjes uit diverse processen zoals ovens, molens en materiaalverwerking af te vangen. Deze filters zijn populair vanwege hun hoge efficiëntie bij het verwijderen van fijnstof. Daarnaast zijn geavanceerde filtratieoplossingen, zoals die van Micronics, ontworpen om te voldoen aan de unieke eisen van de cementindustrie, waardoor de naleving van milieuvoorschriften wordt gewaarborgd en de operationele efficiëntie wordt verbeterd.

Filtersystemen verbeteren de efficiëntie van de cementproductie door effectief stof en fijnstof af te vangen, slijtage van de apparatuur te verminderen en verstoppingen te voorkomen. Dit zorgt voor een soepele werking, minimaliseert downtime en verbetert de productkwaliteit door contaminatie te voorkomen. Goede stofbeheersing draagt ook bij aan de naleving van de regelgeving, waardoor het risico op boetes en milieuproblemen wordt verminderd. Bovendien dragen efficiënte filtersystemen bij aan energiebesparing door de luchtstroom te optimaliseren en drukval in het systeem te verminderen.

Geavanceerde filtratiesystemen in de cementproductie helpen luchtvervuiling te verminderen door fijnstofdeeltjes af te vangen en de uitstoot van schadelijke stoffen te minimaliseren. Ze verbeteren de luchtkwaliteit, zorgen voor naleving van milieuregelgeving en verkleinen de CO2-voetafdruk van de industrie. Door de stofbeheersing te verbeteren, dragen deze systemen ook bij aan de gezondheid en veiligheid van werknemers. Bovendien ondersteunen ze duurzaamheid door de terugwinning en het hergebruik van grondstoffen mogelijk te maken, afval te verminderen en de energie-efficiëntie in cementproductieprocessen te optimaliseren.