Industrial Baghouse Filter Systems

for Cement & Mineral Plants

Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

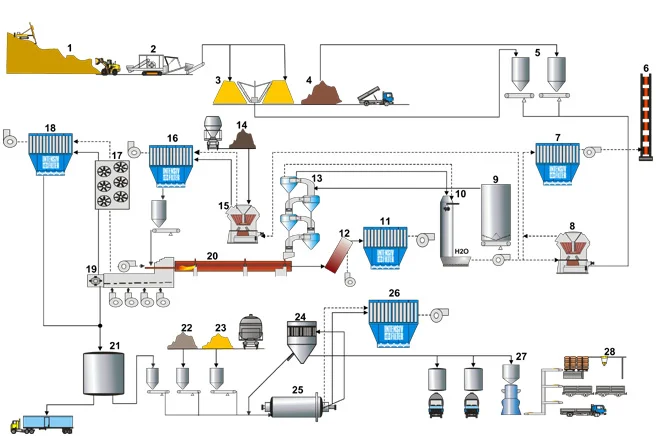

Bag Filters Use Cases in Cement Production Process

Penapis luar

Pengering semburan

Penapis CIP

Katil terbendalir luaran

Pengisian

- 1. Kuari

- 2. Loji penghancur

- 3. Penghomogenan bahan mentah

- 4. Agregat

- 5. Silo makan kilang mentah

- 6. Timbunan utama

- 7. Penapis beg untuk kilang tanur/mentah

- 8. Kilang mentah menegak

- 9. Silo penyusuan bahan mentah

- 10. Menara pendingin gas

- 11. Penapis beg untuk pintasan alkali

- 12. Pintas kebuk pencampuran

- 13. Pra-pemanas siklon

- 14. Arang batu mentah

- 15. Kilang pengisar arang batu menegak

- 16. Penapis beg untuk loji pengisar arang batu

- 17. Penyejuk tiub

- 18. Penapis beg untuk penyejuk klinker

- 19. Penyejuk klinker

- 20. Tanur berputar

- 21. Silo klinker

- 22. Gipsum

- 23. Mineral

- 24. Pemisah

- 25. Kilang kemasan simen

- 26. Penapis beg untuk kilang kemasan simen

- 27. Loji pembungkusan

- 28. Loji paletisasi

Spesifikasi yang Diperlukan

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Data reka bentuk biasa | Kiln-/kilang mentah |

|---|---|

Isipadu gas | < 1,200,000 |

Suhu gas | 85 – 110 kompaun / < 250 langsung |

Jenis habuk | CaCO3, CaO |

Kandungan habuk yang tinggal | < 550 |

Kandungan habuk gas mentah | < 10 |

Pembersihan | dalam talian / luar talian |

Medium penapis | PEA, NX, PPS, PI, GL/PTFE |

Data reka bentuk biasa | pintasan alkali |

|---|---|

Isipadu gas | < 800,000 |

Suhu gas | < 250 |

Jenis habuk | CaCO3, CaO, Alkali |

Kandungan habuk yang tinggal | < 25 |

Kandungan habuk gas mentah | < 10 |

Pembersihan | luar talian |

Medium penapis | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Data reka bentuk biasa | Kilang arang batu |

|---|---|

Isipadu gas | < 450,000 |

Suhu gas | 80 – 110 |

Jenis habuk | arang batu |

Kandungan habuk yang tinggal | < 250 |

Kandungan habuk gas mentah | < 10 |

Pembersihan | dalam talian |

Medium penapis | PEA / PAN |

Data reka bentuk biasa | Penyejuk tiub |

|---|---|

Isipadu gas | < 1,600,000 |

Suhu gas dalam | 250 – 350 |

Suhu gas keluar | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Data reka bentuk biasa | Penyejuk klinker |

|---|---|

Isipadu gas | < 800,000 |

Suhu gas | 120 – 180 |

Jenis habuk | Klinker |

Kandungan habuk gas mentah | 10 – 30 |

Kandungan habuk yang tinggal | < 10 |

Pembersihan | dalam talian |

Medium penapis | PE / NX /PI |

Data reka bentuk biasa | Kilang kemasan simen |

|---|---|

Isipadu gas | < 300,000 |

Suhu gas | 80 – 110 |

Jenis habuk | Simen, sanga |

Kandungan habuk gas mentah | < 350 |

Kandungan habuk yang tinggal | < 10 |

Pembersihan | dalam talian / luar talian |

Medium penapis | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Mengawal habuk yang dijana daripada proses penghancuran dan pengisaran bertenaga tinggi, menangkap zarah halus untuk menghalangnya daripada terlepas ke atmosfera.

Mengurangkan pelepasan daripada proses tanur di mana bahan mentah dipanaskan, mengawal habuk dan zarah bawaan udara lain yang dikeluarkan semasa pengeluaran simen.

Menangkap habuk semasa pengangkutan bahan pukal, seperti batu kapur dan klinker, untuk mengelakkan pembebasan zarah dalam peringkat penyimpanan dan penghantaran.

Meminimumkan pelepasan habuk dalam kawasan pembungkusan dan penyimpanan produk, memastikan produk siap dibungkus dan disimpan dalam persekitaran bebas bahan cemar.

Landskap Kawal Selia untuk Kawalan Habuk |

|---|

Piawaian Kualiti Udara |

Kesihatan dan Keselamatan Pekerja |

Pencegahan Kebakaran dan Letupan |

Perlindungan Alam Sekitar |

Pemantauan dan Pelaporan pelepasan |

Kecekapan Tenaga |

Pengurusan Sisa |

Kualiti dan Konsistensi Produk |

Mengurangkan Masa Henti dan Kos Penyelenggaraan |

Cabaran Kawalan Habuk |

|---|

Tahap Habuk Tinggi |

Risiko Kesihatan Pekerja |

Pematuhan Alam Sekitar |

Bahaya Kebakaran dan Letupan |

Kebimbangan Kualiti Produk |

Haus dan Lusuh Peralatan |

Pencemaran Silang |

Pematuhan Kualiti Udara |

Pertumbuhan Mikrob |

Pertimbangan Utama untuk Kawalan Habuk yang Berkesan |

|---|

Laksanakan Sistem Tangkapan Debu Berkesan |

Kawalan Aliran Udara dan Tekanan yang betul |

Pengurusan Suhu dan Kelembapan |

Sistem Penapisan Berkecekapan Tinggi |

Penyelenggaraan dan Pemeriksaan Berkala |

Pematuhan kepada Piawaian Industri |

Penilaian Kerap Sistem Kawalan Habuk |

Penyesuaian Khusus Proses |

Penilaian dan Pengurangan Risiko |

Berhubung dengan kami untuk Perundingan Pakar

Terokai Perkhidmatan Kami yang Lain!

Soalan Lazim

Dalam industri simen, penyelesaian penapisan yang berkesan adalah penting untuk mengawal pelepasan habuk dan memastikan pematuhan alam sekitar. Sistem penapisan yang biasa digunakan termasuk penapis baghouse, yang menggunakan beg penapis fabrik untuk menangkap zarah halus daripada pelbagai proses seperti tanur, kilang dan pengendalian bahan. Penapis ini digemari kerana kecekapannya yang tinggi dalam mengeluarkan bahan zarah. Selain itu, penyelesaian penapisan termaju, seperti yang ditawarkan oleh Micronics, direka bentuk untuk memenuhi permintaan unik industri simen, memastikan pematuhan kepada peraturan alam sekitar dan meningkatkan kecekapan operasi.

Sistem penapisan meningkatkan kecekapan dalam pengeluaran simen dengan menangkap habuk dan zarah secara berkesan, mengurangkan haus peralatan dan mencegah tersumbat. Ini memastikan operasi lancar, meminimumkan masa henti, dan meningkatkan kualiti produk dengan mencegah pencemaran. Kawalan habuk yang betul juga membantu mengekalkan pematuhan peraturan, mengurangkan risiko denda dan isu alam sekitar. Selain itu, sistem penapisan yang cekap menyumbang kepada penjimatan tenaga dengan mengoptimumkan aliran udara dan mengurangkan penurunan tekanan dalam sistem.

Sistem penapisan lanjutan dalam pengeluaran simen membantu mengurangkan pencemaran udara dengan menangkap zarah habuk halus dan meminimumkan pelepasan bahan pencemar berbahaya. Mereka meningkatkan kualiti udara, memastikan pematuhan terhadap peraturan alam sekitar dan mengurangkan jejak karbon industri. Dengan meningkatkan kawalan habuk, sistem ini juga menyumbang kepada kesihatan dan keselamatan pekerja. Selain itu, ia menyokong kemampanan dengan membolehkan pemulihan dan penggunaan semula bahan mentah, mengurangkan sisa, dan mengoptimumkan kecekapan tenaga dalam proses pembuatan simen.