Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

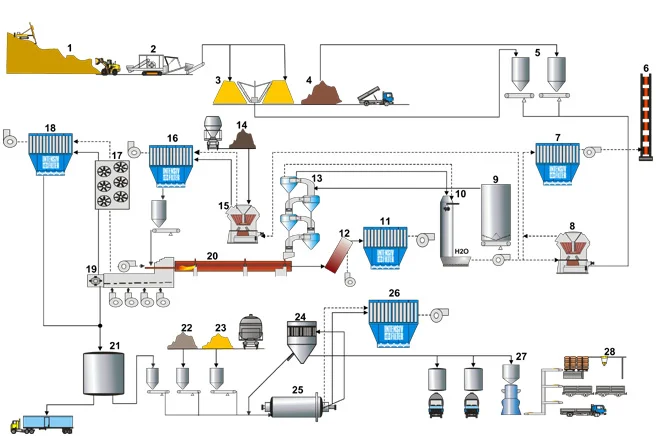

Bag Filters Use Cases in Cement Production Process

외부 필터

분무 건조기

CIP필터

외부 유동화 침대

충전재

- 1. 채석장

- 2. 크러셔 플랜트

- 3. 원료 균질화

- 4. 집계

- 5. 원료밀 공급 사일로

- 6. 메인 스택

- 7. 가마/원료 분쇄기용 백 필터

- 8. 수직 원료 분쇄기

- 9. 원료 공급 사일로

- 10. 가스 컨디셔닝 타워

- 11. 알칼리 바이패스용 백 필터

- 12. 바이패스 믹싱 챔버

- 13. 사이클론 예열기

- 14. 원탄

- 15. 수직 석탄 분쇄기

- 16. 석탄 분쇄 공장용 백 필터

- 17. 튜브형 쿨러

- 18. 클링커 쿨러용 백 필터

- 19. 클링커 쿨러

- 20. 회전로

- 21. 클링커 사일로

- 22. 석고

- 23. 미네랄

- 24. 구분자

- 25. 시멘트 마무리 밀

- 26. 시멘트 마무리 공장용 백 필터

- 27. 포장공장

- 28. 팔레타이징 플랜트

필수 사양

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

일반적인 설계 데이터 | 가마-/원료 분쇄기 |

|---|---|

가스량 | < 1,200,000 |

가스 온도 | 85 – 110 복합 / < 250 직접 |

먼지의 종류 | 탄산칼슘, 탄산칼슘 |

잔류먼지 함량 | < 550 |

원료가스 분진 함량 | < 10 |

청소 | 온라인 / 오프라인 |

필터 매체 | PEA, NX, PPS, PI, GL/PTFE |

일반적인 설계 데이터 | 알칼리 바이패스 |

|---|---|

가스량 | < 800,000 |

가스 온도 | < 250 |

먼지의 종류 | CaCO3, CaO, 알칼리 |

잔류먼지 함량 | < 25 |

원료가스 분진 함량 | < 10 |

청소 | 오프라인 |

필터 매체 | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

일반적인 설계 데이터 | 석탄 분쇄기 |

|---|---|

가스량 | < 450,000 |

가스 온도 | 80~110 |

먼지의 종류 | 석탄 |

잔류먼지 함량 | < 250 |

원료가스 분진 함량 | < 10 |

청소 | 온라인 |

필터 매체 | 완두콩 / 팬 |

일반적인 설계 데이터 | 튜브형 쿨러 |

|---|---|

가스량 | < 1,600,000 |

가스 온도 | 250 – 350 |

가스 온도 나가다 | 120~200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

일반적인 설계 데이터 | 클링커 쿨러 |

|---|---|

가스량 | < 800,000 |

가스 온도 | 120~180 |

먼지의 종류 | 수갑 |

원료가스 분진 함량 | 10~30일 |

잔류먼지 함량 | < 10 |

청소 | 온라인 |

필터 매체 | PE/NX/PI |

일반적인 설계 데이터 | 시멘트 마무리 공장 |

|---|---|

가스량 | < 300,000 |

가스 온도 | 80~110 |

먼지의 종류 | 시멘트, 슬래그 |

원료가스 분진 함량 | < 350 |

잔류먼지 함량 | < 10 |

청소 | 온라인 / 오프라인 |

필터 매체 | 체육/완두콩 |

Our Baghouse Filter Application for the Cement and Minerals

먼지 제어를 위한 규제 환경 |

|---|

대기질 기준 |

근로자 건강 및 안전 |

화재 및 폭발 예방 |

환경 보호 |

배출 모니터링 및 보고 |

에너지 효율성 |

폐기물 관리 |

제품 품질 및 일관성 |

가동 중지 시간 및 유지 관리 비용 감소 |

먼지 제어 과제 |

|---|

높은 먼지 수준 |

근로자 건강 위험 |

환경 준수 |

화재 및 폭발 위험 |

제품 품질 문제 |

장비 마모 및 파손 |

교차 오염 |

대기질 규정 준수 |

미생물 성장 |

효과적인 먼지 제어를 위한 주요 고려 사항 |

|---|

효과적인 먼지 포집 시스템 구현 |

적절한 공기 흐름 및 압력 제어 |

온도 및 습도 관리 |

고효율 여과 시스템 |

정기적인 유지관리 및 검사 |

산업 표준 준수 |

먼지 제어 시스템의 정기적인 평가 |

프로세스별 적응 |

위험 평가 및 완화 |

전문가 상담을 위해 저희에게 연락하세요

다른 서비스를 살펴보세요!

자주 묻는 질문

시멘트 산업에서 효과적인 여과 솔루션은 분진 배출을 제어하고 환경 규정을 준수하는 데 필수적입니다. 일반적으로 사용되는 여과 시스템에는 가마, 제분소, 자재 취급 등 다양한 공정에서 발생하는 미세 입자를 포집하기 위해 직물 필터백을 사용하는 백하우스 필터가 있습니다. 이러한 필터는 미립자 물질 제거 효율이 높아 선호됩니다. 또한, 마이크로닉스(Micronics)와 같은 첨단 여과 솔루션은 시멘트 산업의 고유한 요구 사항을 충족하도록 설계되어 환경 규정을 준수하고 운영 효율성을 향상시킵니다.

여과 시스템은 먼지와 미립자를 효과적으로 포집하여 시멘트 생산 효율을 향상시키고, 장비 마모를 줄이며, 막힘을 방지합니다. 이를 통해 원활한 작동을 보장하고, 가동 중단 시간을 최소화하며, 오염을 방지하여 제품 품질을 향상시킵니다. 또한, 적절한 먼지 관리는 규정 준수를 유지하여 벌금 및 환경 문제의 위험을 줄이는 데 도움이 됩니다. 또한, 효율적인 여과 시스템은 공기 흐름을 최적화하고 시스템 내 압력 강하를 줄여 에너지 절감에도 기여합니다.

시멘트 생산에 사용되는 첨단 여과 시스템은 미세먼지 입자를 포집하고 유해 오염물질 배출을 최소화하여 대기 오염을 줄이는 데 도움을 줍니다. 이러한 시스템은 대기질을 개선하고 환경 규정을 준수하며 업계의 탄소 발자국을 줄입니다. 먼지 제어를 강화함으로써 작업자의 건강과 안전에도 기여합니다. 또한, 시멘트 제조 공정에서 원료 회수 및 재사용, 폐기물 감소, 에너지 효율 최적화를 통해 지속가능성을 지원합니다.