Кеңселер

Штаб-пәтер

Германия

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Велберт, Дойчланд/Германия - +49 20534200990

ОБЛЫСТЫҚ БӨЛІМ

Ұлыбритания

- Қарқынды сүзгі Himenviro UK Limited

47, Бат-стрит WS13BX, Уолсолл Вест Мидлендс, Ұлыбритания - +44 1922 628893

ОБЛЫСТЫҚ БӨЛІМ

Біріккен Араб Әмірліктері

- Қарқынды фильтр Himenviro Technologies FZE – LLC

Іскерлік орталық, Sharjah Publishing City еркін аймағы, Шарджа, БАӘ - +971-556074697

ОБЛЫСТЫҚ БӨЛІМ

Үндістан

- Intensiv-Filter Himenviro Private Limited

D-247/11, сектор-63, Ноида - 201301, Уттар-Прадеш, Үндістан - +91-120-4642-500

ОБЛЫСТЫҚ БӨЛІМ

Үндістан

- Intensiv-Filter Himenviro Private Limited

D-247/11, сектор-63, Ноида - 201301, Уттар-Прадеш, Үндістан - +91-120-4642-500

ОБЛЫСТЫҚ БӨЛІМ

Үндістан

- Intensiv-Filter Himenviro Private Limited

D-247/11, сектор-63, Ноида - 201301, Уттар-Прадеш, Үндістан - +91-120-4642-500

Шыны өнеркәсібінің ауа мен шаңды сүзу шешімдері

Шыны өндіру өнеркәсібі жоғары температурамен, ұсақ шаң түзетін шикізатты қолданумен және ұшпа түтін шығарумен сипатталады. Бұл факторлар жұмысшылардың денсаулығына, қоршаған ортаның сақталуына және өнім сапасына айтарлықтай қауіп төндіреді. Біздің ауа мен шаңды сүзу жүйелері өндірістің маңызды кезеңдерінде ауадағы бөлшектерді, түтіндерді және газдарды тиімді ұстауды қамтамасыз ететін шыны өнеркәсібі үшін арнайы әзірленген. Біздің шешімдеріміз өндірушілерге нормативтік стандарттарды орындауға, жұмысшыларды қорғауға және өнімдердің ластанбай жоғары сапасын сақтауға көмектеседі.

Шыны өнеркәсібіндегі шаңды сүзу процесі

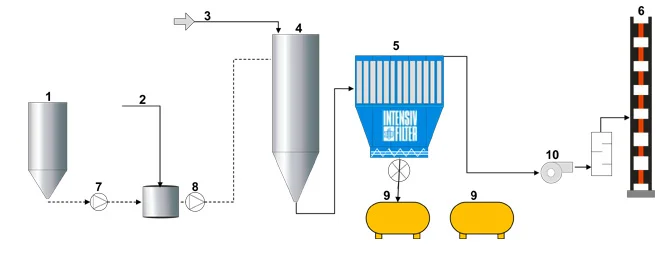

Шыны пешке арналған сүзгі

- 1. NaOH сыйымдылығы

- 2. Су

- 3. Шыны науадан шыққан ыстық газ

- 4. Сөндіргіш реактор

- 5. Шыны пешке арналған сүзгі

- 6. Мұржа

- 7. Дозалау сорғысы

- 8. Сөндіргіш сорғы

- 9. Тасымалдау контейнері

- 10. Индукцияланған тартпа

Қажетті спецификациялар

Типтік дизайн деректері | Қалдық жану пештері |

|---|---|

Газ көлемі | 38,000 |

Газ температурасы | 180 – 200 |

Шаң түрі | Натрий сульфаты, сода, борак, кварц |

Шикі газ шаңының құрамы | 10 – 25 |

Қалдық шаң мөлшері | < 10 |

Тазалау | желіден тыс |

Сүзгі ортасы | Полимид |

Сорбент | Натрий гидроксиді |

Шыны өнеркәсібінің шаңын бақылауға арналған қосымшалар

Кремний тотығы, сода күлі және әктас сияқты шикізатты өңдеу және сақтау кезінде ауадағы шаңды сүзеді, шаңның нысанның басқа жерлеріне таралмауын қамтамасыз етеді.

Балқыту процесі кезінде пайда болатын ауадағы ластаушы заттар мен бөлшектерді бақылайды, бұл жоғары температуралы пеш алаңдарының айналасында таза ауаны қамтамасыз етеді.

Шыны бұйымдарын қалыптау және қалыптау кезінде пайда болатын шаң мен ұсақ бөлшектерді азайтады, ластануды болдырмайды және өнімнің тұтастығын жақсартады.

Шаңды бақылауға арналған нормативтік ландшафт |

|---|

Ауа сапасы стандарттарына сәйкестік |

Жұмысшылардың денсаулығы мен қауіпсіздігін сақтау |

Өрт және жарылыс қаупінің алдын алу |

Қоршаған ортаны қорғау талаптарын сақтау |

Нақты уақыттағы шығарындыларды бақылау |

Ыстыққа және коррозияға төзімділік |

Қысқартылған тоқтау уақыты және техникалық қызмет көрсету шығындары |

Сапа және өнімнің сәйкестігі |

Операциялық шығындарды үнемдеу |

Шыны өнеркәсібіндегі шаңды бақылау қиындықтары |

|---|

Шаңның жоғары болуы |

Жылу және коррозиялық орталар |

Жұмысшылардың қауіпсіздік тәуекелдері |

Жану және жарылыс қаупі |

Өнімнің сапасы мен тазалығын сақтау |

Өнімнің ластануы |

Жабдықтың тозуы |

Түтіндер және газ тәрізді шығарындылар |

Айқас ластану |

Шаңды тиімді бақылауға арналған негізгі ойлар |

|---|

Шаң мен түтінді тиімді ұстау |

Химиялық және ыстыққа төзімділік |

Оңтайландырылған ауа ағыны мен қысымды басқару |

Жетілдірілген фильтрациялық материалдар |

Күнделікті техникалық қызмет көрсету және тексерулер |

Нормативтік стандарттарға сәйкестік |

Таңдалған фильтрация шешімдері |

Қауіпті химиялық заттар үшін тәуекелді азайту |

Икемді жүйе конфигурациялары |

Мамандық кеңес алу үшін бізбен байланысыңыз

Біздің басқа қызметтерімізді зерттеңіз!

Жиі қойылатын сұрақтар

Шыны өндірісі құм, сода күлі, әктас және куллет сияқты шикізатты өңдеу кезінде айтарлықтай мөлшерде ұсақ, абразивті шаңды, әсіресе кремнеземге бай бөлшектерді тудырады. Бұл бөлшектер силикоз және тыныс алу мәселелері сияқты денсаулыққа елеулі қауіп төндіреді. Тиімді сүзу жұмысшылардың қауіпсіздігін қамтамасыз етеді, жабдықтың тозуын болдырмайды, өнімнің тазалығын сақтайды және 99,9%-ге дейінгі түсіру тиімділігін талап ететін қоршаған ортаны қорғау ережелерін сақтауға мүмкіндік береді.

Әйнекті ұсақтау және өңдеу кезіндегі шаң өте абразивті және химиялық инертті, ал құрамында кремний диоксиді микроскопиялық өлшемдерде оны канцерогенді етеді. Күллет шаңы өте ретсіз және абразивті, сүзгі материалының тозуын тездетеді және сүзгі қалталарының немесе картридждердің тез бұзылуын болдырмау үшін берік кіріс конструкциясын, ауыр жүк көтергіш ыдыстарды және ауа ағынын басқаруды қажет етеді.

Шыны қондырғылары, әдетте, жоғары тиімді бөлшектерді бақылауға қол жеткізу үшін мата сүзгілерін (қапшықтар) пайдаланады. Жоғары температура немесе ауыр кремний тотығы абразивтілігі бар қолданбаларда тозуға төзімді баспа құралдары немесе картридж түріндегі коллекторлары бар ұзаққа созылатын сөмке жүйелерін таңдауға болады. Қышқыл газдарды немесе ұшпа эмиссияларды тудыратын процестер үшін қосымша дымқыл скрубберлер қажет болуы мүмкін.