Industrial Baghouse Filter Systems

for Cement & Mineral Plants

Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

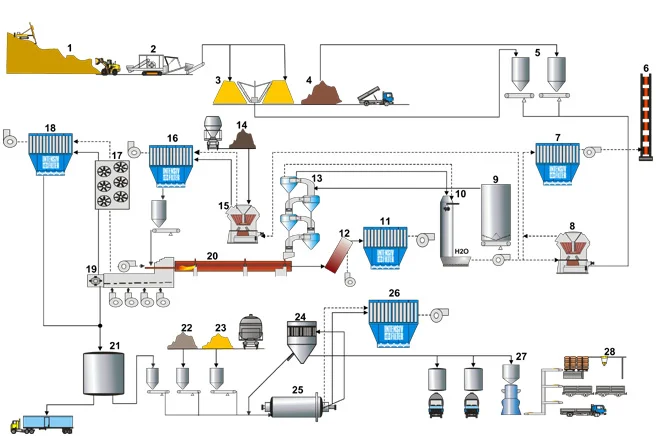

Bag Filters Use Cases in Cement Production Process

Filtro esterno

Essiccatore a spruzzo

Filtro CIP

Letto fluido esterno

Riempimento

- 1. Cava

- 2. Impianto di frantumazione

- 3. Omogeneizzazione delle materie prime

- 4. Aggregati

- 5. Silo di alimentazione del mulino grezzo

- 6. Pila principale

- 7. Filtro a sacco per forno/mulino per materie prime

- 8. Mulino verticale per materie prime

- 9. Silo di alimentazione delle materie prime

- 10. Torre di condizionamento del gas

- 11. Filtro a sacco per bypass alcalino

- 12. Bypass camera di miscelazione

- 13. Preriscaldatore ciclonico

- 14. Carbone grezzo

- 15. Mulino verticale per la macinazione del carbone

- 16. Filtro a sacco per impianto di macinazione del carbone

- 17. Refrigeratore tubolare

- 18. Filtro a sacco per raffreddatore clinker

- 19. Raffreddatore di clinker

- 20. Forno rotante

- 21. Silo per clinker

- 22. Gesso

- 23. Minerali

- 24. Separatore

- 25. Mulino di finitura del cemento

- 26. Filtro a sacco per mulino di finitura del cemento

- 27. Impianto di confezionamento

- 28. Impianto di pallettizzazione

Specifiche richieste

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Dati di progettazione tipici | Forno/mulino per materie prime |

|---|---|

Volume del gas | < 1.200.000 |

Temperatura del gas | 85 – 110 composto / < 250 diretto |

Tipo di polvere | CaCO3, CaO |

Contenuto di polvere residua | < 550 |

Contenuto di polvere di gas grezzo | < 10 |

Pulizia | in linea / fuori linea |

Mezzo filtrante | PEA, NX, PPS, PI, GL/PTFE |

Dati di progettazione tipici | Bypass alcalino |

|---|---|

Volume del gas | < 800.000 |

Temperatura del gas | < 250 |

Tipo di polvere | CaCO3, CaO, Alcali |

Contenuto di polvere residua | < 25 |

Contenuto di polvere di gas grezzo | < 10 |

Pulizia | Non in linea |

Mezzo filtrante | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Dati di progettazione tipici | Mulino a carbone |

|---|---|

Volume del gas | < 450.000 |

Temperatura del gas | 80 – 110 |

Tipo di polvere | Carbone |

Contenuto di polvere residua | < 250 |

Contenuto di polvere di gas grezzo | < 10 |

Pulizia | in linea |

Mezzo filtrante | PISELLO / PAN |

Dati di progettazione tipici | Raffreddatore tubolare |

|---|---|

Volume del gas | < 1.600.000 |

Temperatura del gas in | 250 – 350 |

Temperatura del gas fuori | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Dati di progettazione tipici | Raffreddatore di clinker |

|---|---|

Volume del gas | < 800.000 |

Temperatura del gas | 120 – 180 |

Tipo di polvere | Clinker |

Contenuto di polvere di gas grezzo | 10 – 30 |

Contenuto di polvere residua | < 10 |

Pulizia | in linea |

Mezzo filtrante | PE/NX/PI |

Dati di progettazione tipici | Mulino di finitura del cemento |

|---|---|

Volume del gas | < 300.000 |

Temperatura del gas | 80 – 110 |

Tipo di polvere | Cemento, scorie |

Contenuto di polvere di gas grezzo | < 350 |

Contenuto di polvere residua | < 10 |

Pulizia | in linea / fuori linea |

Mezzo filtrante | PE/PEA |

Our Baghouse Filter Application for the Cement and Minerals

Controlla la polvere generata dai processi di frantumazione e macinazione ad alta energia, catturando le particelle fini ed evitando che si disperdano nell'atmosfera.

Riduce le emissioni derivanti dai processi dei forni in cui vengono riscaldate le materie prime, controllando la polvere e altre particelle sospese nell'aria rilasciate durante la produzione del cemento.

Cattura la polvere durante il trasporto di materiali sfusi, come calcare e clinker, per impedire il rilascio di particelle nelle fasi di stoccaggio e trasporto.

Riduce al minimo le emissioni di polvere nelle aree di imballaggio e stoccaggio dei prodotti, garantendo che i prodotti finiti vengano imballati e conservati in un ambiente privo di contaminanti.

Panorama normativo per il controllo della polvere |

|---|

Standard di qualità dell'aria |

Salute e sicurezza dei lavoratori |

Prevenzione incendi ed esplosioni |

Protezione ambientale |

Monitoraggio e segnalazione delle emissioni |

Efficienza energetica |

Gestione dei rifiuti |

Qualità e coerenza del prodotto |

Riduzione dei tempi di inattività e dei costi di manutenzione |

Sfide nel controllo della polvere |

|---|

alti livelli di polvere |

Rischi per la salute dei lavoratori |

Conformità ambientale |

Rischi di incendio ed esplosione |

Problemi di qualità del prodotto |

Usura e deterioramento delle attrezzature |

Contaminazione incrociata |

Conformità alla qualità dell'aria |

Crescita microbica |

Considerazioni chiave per un controllo efficace della polvere |

|---|

Implementare sistemi efficaci di cattura della polvere |

Controllo corretto del flusso d'aria e della pressione |

Gestione della temperatura e dell'umidità |

Sistemi di filtrazione ad alta efficienza |

Manutenzione e ispezione regolari |

Aderenza agli standard del settore |

Valutazione frequente del sistema di controllo della polvere |

Adattamenti specifici del processo |

Valutazione e mitigazione del rischio |

Contattaci per una consulenza esperta

Scopri gli altri nostri servizi!

Domande frequenti

Nell'industria del cemento, soluzioni di filtrazione efficaci sono essenziali per controllare le emissioni di polveri e garantire la conformità ambientale. I sistemi di filtrazione comunemente utilizzati includono filtri a maniche, che utilizzano sacchi filtranti in tessuto per catturare le particelle fini provenienti da vari processi come forni, mulini e movimentazione dei materiali. Questi filtri sono apprezzati per la loro elevata efficienza nella rimozione del particolato. Inoltre, soluzioni di filtrazione avanzate, come quelle offerte da Micronics, sono progettate per soddisfare le specifiche esigenze dell'industria del cemento, garantendo la conformità alle normative ambientali e migliorando l'efficienza operativa.

I sistemi di filtrazione migliorano l'efficienza nella produzione del cemento catturando efficacemente polvere e particolato, riducendo l'usura delle attrezzature e prevenendo gli intasamenti. Ciò garantisce un funzionamento regolare, riduce al minimo i tempi di fermo e migliora la qualità del prodotto prevenendo la contaminazione. Un adeguato controllo delle polveri contribuisce inoltre a mantenere la conformità normativa, riducendo il rischio di multe e problemi ambientali. Inoltre, sistemi di filtrazione efficienti contribuiscono al risparmio energetico ottimizzando il flusso d'aria e riducendo le perdite di carico nel sistema.

I sistemi di filtrazione avanzati nella produzione del cemento contribuiscono a ridurre l'inquinamento atmosferico catturando le particelle di polvere fine e riducendo al minimo le emissioni di inquinanti nocivi. Migliorano la qualità dell'aria, garantendo il rispetto delle normative ambientali e riducendo l'impronta di carbonio del settore. Migliorando il controllo delle polveri, questi sistemi contribuiscono anche alla salute e alla sicurezza dei lavoratori. Inoltre, favoriscono la sostenibilità consentendo il recupero e il riutilizzo delle materie prime, riducendo gli sprechi e ottimizzando l'efficienza energetica nei processi di produzione del cemento.