Uffici

SEDE CENTRALE

Germania

- Filtro intensivo Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Germania/Germania - +49 20534200990

UFFICIO REGIONALE

Gran Bretagna

- Filtro intensivo Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Gran Bretagna - +44 1922 628893

UFFICIO REGIONALE

Emirati Arabi Uniti

- Filtro intensivo Himenviro Technologies FZE – LLC

Centro commerciale, Sharjah Publishing City Free Zone, Sharjah, Emirati Arabi Uniti - +971-556074697

UFFICIO REGIONALE

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Settore-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

UFFICIO REGIONALE

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Settore-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

UFFICIO REGIONALE

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Settore-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Soluzioni per la filtrazione dell'aria e della polvere nell'industria del vetro

L'industria vetraria è caratterizzata da temperature elevate, dall'utilizzo di materie prime che generano polveri sottili e dalla produzione di fumi volatili. Questi fattori comportano rischi significativi per la salute dei lavoratori, la conformità ambientale e la qualità del prodotto. I nostri sistemi di filtrazione dell'aria e delle polveri sono progettati specificamente per l'industria vetraria, garantendo un'efficace cattura di particolato, fumi e gas aerodispersi nelle fasi critiche della produzione. Le nostre soluzioni aiutano i produttori a soddisfare gli standard normativi, a proteggere i lavoratori e a garantire che i prodotti mantengano la loro elevata qualità senza contaminazioni.

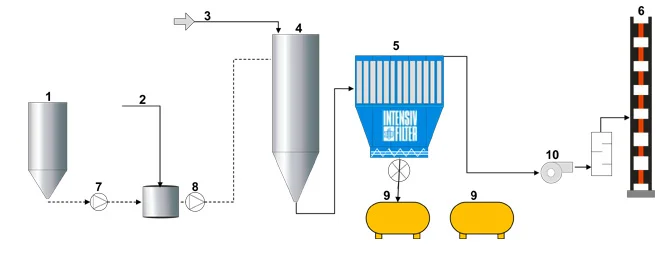

Processo di filtrazione della polvere nell'industria del vetro

Filtro per forno per vetro

- 1. Serbatoio NaOH

- 2. Acqua

- 3. Gas caldo dal contenitore di vetro

- 4. Reattore di spegnimento

- 5. Filtro per forno per vetro

- 6. Camino

- 7. Pompa dosatrice

- 8. Pompa di spegnimento

- 9. Contenitore per il trasporto

- 10. Bozza indotta

Specifiche richieste

Dati di progettazione tipici | Forni a combustione di residui |

|---|---|

Volume del gas | 38,000 |

Temperatura del gas | 180 – 200 |

Tipo di polvere | Solfato di sodio, soda, borace, quarzo |

Contenuto di polvere di gas grezzo | 10 – 25 |

Contenuto di polvere residua | < 10 |

Pulizia | Non in linea |

Mezzo filtrante | Poliimmide |

Assorbente | Idrossido di sodio |

Applicazioni per il controllo della polvere nell'industria del vetro

Filtra la polvere sospesa nell'aria durante la manipolazione e lo stoccaggio di materie prime come silice, carbonato di sodio e calcare, assicurando che la polvere non si propaghi in altre aree della struttura.

Controlla gli inquinanti atmosferici e il particolato prodotti durante il processo di fusione, garantendo aria pulita attorno alle aree dei forni ad alta temperatura.

Riduce la polvere e le particelle fini generate durante la formatura e lo stampaggio dei prodotti in vetro, prevenendo la contaminazione e migliorando l'integrità del prodotto.

Panorama normativo per il controllo della polvere |

|---|

Conformità agli standard di qualità dell'aria |

Conformità alla salute e sicurezza dei lavoratori |

Prevenzione dei rischi di incendio ed esplosione |

Conformità alla tutela ambientale |

Monitoraggio delle emissioni in tempo reale |

Resistenza al calore e alla corrosione |

Riduzione dei tempi di inattività e dei costi di manutenzione |

Qualità e coerenza del prodotto |

Risparmio sui costi operativi |

Sfide nel controllo della polvere nell'industria del vetro |

|---|

Elevata generazione di polvere |

Ambienti caldi e corrosivi |

Rischi per la sicurezza dei lavoratori |

Rischi di combustione ed esplosione |

Mantenimento della qualità e della purezza del prodotto |

Contaminazione del prodotto |

Usura e deterioramento delle attrezzature |

Fumi ed emissioni gassose |

Contaminazione incrociata |

Considerazioni chiave per un controllo efficace della polvere |

|---|

Cattura efficiente di polveri e fumi |

Resistenza chimica e termica |

Gestione ottimizzata del flusso d'aria e della pressione |

Materiali di filtrazione avanzati |

Manutenzione e ispezioni di routine |

Conformità agli standard normativi |

Soluzioni di filtrazione personalizzate |

Mitigazione del rischio per sostanze chimiche pericolose |

Configurazioni di sistema flessibili |

Contattaci per una consulenza esperta

Scopri gli altri nostri servizi!

Domande frequenti

La produzione del vetro genera quantità significative di polveri fini e abrasive, in particolare particelle ricche di silice, durante la manipolazione di materie prime come sabbia, carbonato di sodio, calcare e rottame di vetro. Queste particelle rappresentano gravi rischi per la salute, come silicosi e problemi respiratori. Una filtrazione efficace garantisce la sicurezza dei lavoratori, previene l'usura delle attrezzature, mantiene la purezza del prodotto e consente la conformità alle normative ambientali che richiedono efficienze di cattura fino al 99,9%.

La polvere derivante dalla frantumazione e dalla manipolazione del vetro è estremamente abrasiva e chimicamente inerte, mentre il contenuto di silice la rende cancerogena a dimensioni microscopiche. La polvere di vetro di scarto è altamente irregolare e abrasiva, accelerando l'usura dei mezzi filtranti e richiedendo una progettazione robusta dell'ingresso, tramogge robuste e una gestione del flusso d'aria per prevenire la rapida degradazione dei sacchetti o delle cartucce filtranti.

Gli impianti per la lavorazione del vetro utilizzano tipicamente filtri in tessuto (filtri a maniche) per ottenere un controllo del particolato ad alta efficienza. Nelle applicazioni che prevedono alte temperature o elevata abrasività della silice, possono essere preferibili sistemi a maniche durevoli con media resistenti all'abrasione o collettori a cartuccia. Per i processi che generano gas acidi o emissioni volatili, potrebbero essere necessari scrubber a umido supplementari.