Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

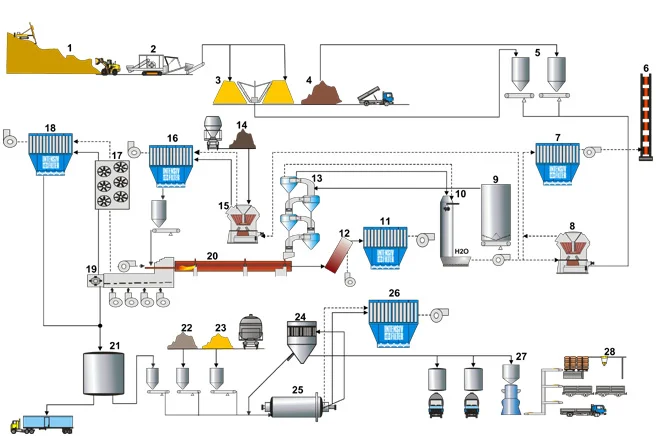

Bag Filters Use Cases in Cement Production Process

Filter luar

Pengering semprot

penyaring CIP

Tempat tidur terfluidisasi eksternal

Isian

- 1. Tambang

- 2. Pabrik penghancur

- 3. Homogenisasi bahan baku

- 4. Agregat

- 5. Silo pengumpanan pabrik bahan baku

- 6. Tumpukan utama

- 7. Filter kantong untuk kiln/penggilingan mentah

- 8. Penggilingan vertikal

- 9. Silo pengumpanan bahan baku

- 10. Menara pendingin gas

- 11. Filter kantong untuk bypass alkali

- 12. Ruang pencampuran bypass

- 13. Pemanas awal siklon

- 14. Batubara mentah

- 15. Pabrik penggilingan batu bara vertikal

- 16. Filter kantong untuk pabrik penggilingan batu bara

- 17. Pendingin tabung

- 18. Filter kantong untuk pendingin klinker

- 19. Pendingin klinker

- 20. Tungku putar

- 21. Silo klinker

- 22. Gipsum

- 23. Mineral

- 24. Pemisah

- 25. Pabrik semen

- 26. Filter kantong untuk pabrik semen

- 27. Pabrik pengemasan

- 28. Pabrik paletisasi

Spesifikasi yang Diperlukan

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Data desain tipikal | Kiln-/penggilingan mentah |

|---|---|

Volume gasnya | < 1.200.000 |

Suhu gas | 85 – 110 senyawa / < 250 langsung |

Jenis debu | CaCO3, CaO |

Kandungan debu sisa | < 550 |

Kandungan debu gas mentah | < 10 |

Pembersihan | daring / luring |

Media penyaring | PEA, NX, PPS, PI, GL/PTFE |

Data desain tipikal | melewati alkali |

|---|---|

Volume gasnya | < 800.000 |

Suhu gas | < 250 |

Jenis debu | CaCO3, CaO, Alkali |

Kandungan debu sisa | < 25 |

Kandungan debu gas mentah | < 10 |

Pembersihan | luring |

Media penyaring | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Data desain tipikal | Pabrik batu bara |

|---|---|

Volume gasnya | < 450.000 |

Suhu gas | 80 – 110 |

Jenis debu | Batu bara |

Kandungan debu sisa | < 250 |

Kandungan debu gas mentah | < 10 |

Pembersihan | on line |

Media penyaring | KACANG POLONG / PAN |

Data desain tipikal | Pendingin tabung |

|---|---|

Volume gasnya | < 1.600.000 |

Suhu gas di | 250 – 350 |

Suhu gas keluar | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Data desain tipikal | Pendingin klinker |

|---|---|

Volume gasnya | < 800.000 |

Suhu gas | 120 – 180 |

Jenis debu | Klinker |

Kandungan debu gas mentah | 10 – 30 |

Kandungan debu sisa | < 10 |

Pembersihan | on line |

Media penyaring | PE / NX / PI |

Data desain tipikal | Pabrik semen |

|---|---|

Volume gasnya | < 300.000 |

Suhu gas | 80 – 110 |

Jenis debu | Semen, terak |

Kandungan debu gas mentah | < 350 |

Kandungan debu sisa | < 10 |

Pembersihan | daring / luring |

Media penyaring | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Mengontrol debu yang dihasilkan dari proses penghancuran dan penggilingan berenergi tinggi, menangkap partikel halus untuk mencegahnya keluar ke atmosfer.

Mengurangi emisi dari proses kiln tempat bahan baku dipanaskan, mengendalikan debu dan partikel udara lainnya yang dilepaskan selama produksi semen.

Menangkap debu selama pengangkutan material curah, seperti batu kapur dan klinker, untuk mencegah pelepasan partikel pada tahap penyimpanan dan pengangkutan.

Meminimalkan emisi debu di area pengemasan dan penyimpanan produk, memastikan bahwa produk jadi dikemas dan disimpan di lingkungan bebas kontaminan.

Lanskap Regulasi untuk Pengendalian Debu |

|---|

Standar Kualitas Udara |

Kesehatan dan Keselamatan Pekerja |

Pencegahan Kebakaran dan Ledakan |

Perlindungan Lingkungan |

Pemantauan dan Pelaporan Emisi |

Efisiensi Energi |

Pengelolaan sampah |

Kualitas dan Konsistensi Produk |

Mengurangi Waktu Henti dan Biaya Perawatan |

Tantangan Pengendalian Debu |

|---|

Tingkat Debu Tinggi |

Risiko Kesehatan Pekerja |

Kepatuhan Lingkungan |

Bahaya Kebakaran dan Ledakan |

Kekhawatiran Kualitas Produk |

Keausan Peralatan |

Kontaminasi Silang |

Kepatuhan Kualitas Udara |

Pertumbuhan Mikroba |

Pertimbangan Utama untuk Pengendalian Debu yang Efektif |

|---|

Terapkan Sistem Penangkapan Debu yang Efektif |

Kontrol Aliran Udara dan Tekanan yang Tepat |

Manajemen Suhu dan Kelembaban |

Sistem Filtrasi Efisiensi Tinggi |

Perawatan dan Inspeksi Rutin |

Kepatuhan terhadap Standar Industri |

Penilaian Sering Sistem Pengendalian Debu |

Adaptasi Spesifik Proses |

Penilaian dan Mitigasi Risiko |

Hubungi kami untuk Konsultasi Ahli

Jelajahi Layanan Kami Lainnya!

Pertanyaan yang Sering Diajukan

Dalam industri semen, solusi filtrasi yang efektif sangat penting untuk mengendalikan emisi debu dan memastikan kepatuhan lingkungan. Sistem filtrasi yang umum digunakan meliputi filter baghouse, yang memanfaatkan kantong filter kain untuk menangkap partikel halus dari berbagai proses seperti kiln, penggilingan, dan penanganan material. Filter ini disukai karena efisiensinya yang tinggi dalam menghilangkan partikel. Selain itu, solusi filtrasi canggih, seperti yang ditawarkan oleh Micronics, dirancang untuk memenuhi kebutuhan unik industri semen, memastikan kepatuhan terhadap peraturan lingkungan, dan meningkatkan efisiensi operasional.

Sistem filtrasi meningkatkan efisiensi produksi semen dengan menangkap debu dan partikulat secara efektif, mengurangi keausan peralatan, dan mencegah penyumbatan. Hal ini memastikan kelancaran operasional, meminimalkan waktu henti, dan meningkatkan kualitas produk dengan mencegah kontaminasi. Pengendalian debu yang tepat juga membantu menjaga kepatuhan terhadap peraturan, mengurangi risiko denda dan masalah lingkungan. Selain itu, sistem filtrasi yang efisien berkontribusi pada penghematan energi dengan mengoptimalkan aliran udara dan mengurangi penurunan tekanan dalam sistem.

Sistem filtrasi canggih dalam produksi semen membantu mengurangi polusi udara dengan menangkap partikel debu halus dan meminimalkan emisi polutan berbahaya. Sistem ini meningkatkan kualitas udara, memastikan kepatuhan terhadap peraturan lingkungan, dan mengurangi jejak karbon industri. Dengan meningkatkan pengendalian debu, sistem ini juga berkontribusi pada kesehatan dan keselamatan pekerja. Selain itu, sistem ini mendukung keberlanjutan dengan memungkinkan pemulihan dan penggunaan kembali bahan baku, mengurangi limbah, dan mengoptimalkan efisiensi energi dalam proses produksi semen.