Bureaux

SIÈGE SOCIAL

Allemagne

- Filtre intensif Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Allemagne - +49 20534200990

BUREAU RÉGIONAL

Grande-Bretagne

- Filtre intensif Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Grande-Bretagne - +44 1922 628893

BUREAU RÉGIONAL

Émirats arabes unis

- Filtre intensif Himenviro Technologies FZE – LLC

Centre d'affaires, Sharjah Publishing City Free Zone, Sharjah, Émirats arabes unis - +971-556074697

BUREAU RÉGIONAL

Inde

- Filtre intensif Himenviro Private Limited

D-247/11, Secteur-63, Noida - 201301, Uttar Pradesh, Inde - +91-120-4642-500

BUREAU RÉGIONAL

Inde

- Filtre intensif Himenviro Private Limited

D-247/11, Secteur-63, Noida - 201301, Uttar Pradesh, Inde - +91-120-4642-500

BUREAU RÉGIONAL

Inde

- Filtre intensif Himenviro Private Limited

D-247/11, Secteur-63, Noida - 201301, Uttar Pradesh, Inde - +91-120-4642-500

Solutions de filtration de l'air et de la poussière pour l'industrie du verre

L'industrie verrière se caractérise par des températures élevées, l'utilisation de matières premières générant des poussières fines et la production de fumées volatiles. Ces facteurs présentent des risques importants pour la santé des travailleurs, le respect de l'environnement et la qualité des produits. Nos systèmes de filtration de l'air et des poussières sont spécialement conçus pour l'industrie verrière et garantissent une capture efficace des particules, des fumées et des gaz en suspension dans l'air aux étapes critiques de la production. Nos solutions aident les fabricants à respecter les normes réglementaires, à protéger les travailleurs et à garantir la qualité élevée des produits sans contamination.

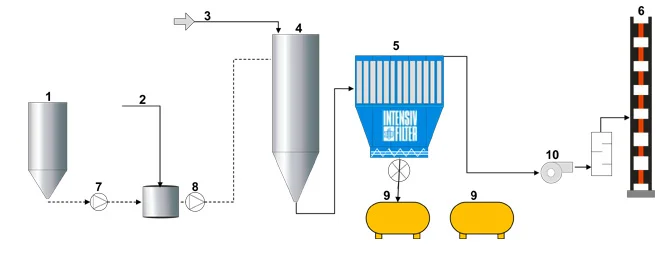

Procédé de filtration des poussières dans l'industrie du verre

Filtre pour four à verre

- 1. Réservoir de NaOH

- 2. Eau

- 3. Gaz chaud provenant du bac en verre

- 4. Réacteur de trempe

- 5. Filtre pour four à verre

- 6. Cheminée

- 7. Pompe doseuse

- 8. Pompe de trempe

- 9. Conteneur de transport

- 10. Tirage induit

Spécifications requises

Données de conception typiques | Fours à combustion de résidus |

|---|---|

Volume de gaz | 38,000 |

Température du gaz | 180 – 200 |

Type de poussière | Sulfate de sodium, soude, borax, quartz |

Teneur en poussières de gaz brut | 10 – 25 |

Teneur en poussières résiduelles | < 10 |

Nettoyage | hors ligne |

Matériau filtrant | Polyimide |

Absorbant | Hydroxyde de sodium |

Applications pour le contrôle de la poussière dans l'industrie du verre

Filtre la poussière en suspension dans l'air lors de la manipulation et du stockage de matières premières telles que la silice, le carbonate de sodium et le calcaire, garantissant ainsi que la poussière ne se propage pas à d'autres zones de l'installation.

Contrôle les polluants atmosphériques et les particules produites pendant le processus de fusion, garantissant un air pur autour des zones de four à haute température.

Réduit la poussière et les particules fines générées lors du formage et du moulage des produits en verre, empêchant la contamination et améliorant l'intégrité du produit.

Paysage réglementaire pour le contrôle de la poussière |

|---|

Conformité aux normes de qualité de l'air |

Conformité en matière de santé et de sécurité des travailleurs |

Prévention des risques d'incendie et d'explosion |

Conformité en matière de protection de l'environnement |

Surveillance des émissions en temps réel |

Résistance à la chaleur et à la corrosion |

Réduction des temps d'arrêt et des coûts de maintenance |

Qualité et cohérence du produit |

Économies sur les coûts opérationnels |

Les défis du contrôle de la poussière dans l'industrie du verre |

|---|

Forte production de poussière |

Environnements chauds et corrosifs |

Risques pour la sécurité des travailleurs |

Risques de combustion et d'explosion |

Maintenir la qualité et la pureté du produit |

Contamination du produit |

Usure de l'équipement |

Fumées et émissions gazeuses |

Contamination croisée |

Considérations clés pour un contrôle efficace de la poussière |

|---|

Capture efficace des poussières et des fumées |

Résistance chimique et thermique |

Gestion optimisée du flux d'air et de la pression |

Matériaux de filtration avancés |

Entretien et inspections de routine |

Conformité aux normes réglementaires |

Solutions de filtration personnalisées |

Atténuation des risques liés aux produits chimiques dangereux |

Configurations système flexibles |

Contactez-nous pour une consultation d'expert

Découvrez nos autres services !

Questions fréquemment posées

La production de verre génère d'importantes quantités de poussières fines et abrasives, notamment des particules riches en silice, lors de la manipulation de matières premières telles que le sable, le carbonate de sodium, le calcaire et le calcin. Ces particules présentent de graves risques pour la santé, tels que la silicose et des problèmes respiratoires. Une filtration efficace assure la sécurité des travailleurs, prévient l'usure des équipements, préserve la pureté du produit et permet de respecter les réglementations environnementales exigeant des rendements de captage allant jusqu'à 99,91 TP3T.

La poussière issue du broyage et de la manutention du verre est extrêmement abrasive et chimiquement inerte, tandis que sa teneur en silice la rend cancérigène à l'échelle microscopique. La poussière de calcin est très irrégulière et abrasive, ce qui accélère l'usure du média filtrant et nécessite une conception d'entrée robuste, des trémies robustes et une gestion du flux d'air pour éviter la dégradation rapide des sacs ou des cartouches filtrantes.

Les usines de verre utilisent généralement des filtres à manches pour un contrôle efficace des particules. Pour les applications impliquant des températures élevées ou une forte abrasivité de la silice, des systèmes de filtres à manches durables avec média résistant à l'abrasion ou des collecteurs à cartouche peuvent être privilégiés. Pour les procédés générant des gaz acides ou des émissions volatiles, des épurateurs humides supplémentaires peuvent être nécessaires.