Mga opisina

HEADQUARTER

Alemanya

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REHIYONAL NA TANGGAPAN

Great Britain

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REHIYONAL NA TANGGAPAN

United Arab Emirates

- Intensive Filter Himenviro Technologies FZE – LLC

Business Center, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REHIYONAL NA TANGGAPAN

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REHIYONAL NA TANGGAPAN

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REHIYONAL NA TANGGAPAN

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Mga Solusyon sa Pag-filter ng Hangin at Alikabok sa Industriya ng Salamin

Ang industriya ng paggawa ng salamin ay nailalarawan sa pamamagitan ng mataas na temperatura, ang paggamit ng mga hilaw na materyales na bumubuo ng pinong alikabok, at ang paggawa ng mga pabagu-bago ng usok. Ang mga salik na ito ay nagdudulot ng malaking panganib sa kalusugan ng manggagawa, pagsunod sa kapaligiran, at kalidad ng produkto. Ang aming mga air at dust filtration system ay partikular na ginawa para sa industriya ng salamin, na tinitiyak ang mahusay na pagkuha ng airborne particulate matter, fumes, at gas sa mga kritikal na yugto ng produksyon. Tinutulungan ng aming mga solusyon ang mga tagagawa na matugunan ang mga pamantayan ng regulasyon, protektahan ang mga manggagawa, at matiyak na mapanatili ng mga produkto ang kanilang mataas na kalidad nang walang kontaminasyon.

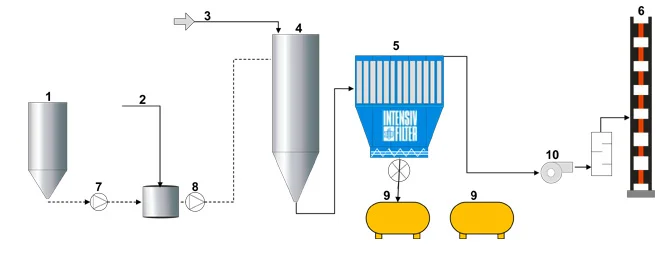

Proseso ng Pagsala ng Alikabok sa Industriya ng Salamin

Salain para sa glass-kiln

- 1. tangke ng NaOH

- 2. Tubig

- 3. Mainit na gas mula sa labangan ng salamin

- 4. Pawiin ang reaktor

- 5. Salain para sa glass-kiln

- 6. Chimney

- 7. Dosing pump

- 8. Pawiin ang bomba

- 9. Lalagyan ng transportasyon

- 10. Induced draft

Mga kinakailangang pagtutukoy

Karaniwang data ng disenyo | Nalalabi na mga hurno ng pagkasunog |

|---|---|

Dami ng gas | 38,000 |

Temperatura ng gas | 180 – 200 |

Uri ng alikabok | Sodium sulphate, soda, borax, kuwarts |

Hilaw na nilalaman ng alikabok ng gas | 10 – 25 |

Ang natitirang nilalaman ng alikabok | < 10 |

Paglilinis | offline |

Filter medium | Polyimide |

Sorbent | Sodium hydroxide |

Mga Aplikasyon para sa Pagkontrol ng Alikabok sa Industriya ng Salamin

Sinasala ang airborne dust sa panahon ng paghawak at pag-iimbak ng mga hilaw na materyales tulad ng silica, soda ash, at limestone, na tinitiyak na ang alikabok ay hindi kumalat sa ibang mga lugar ng pasilidad.

Kinokontrol ang mga airborne pollutant at particulate matter na ginawa sa panahon ng proseso ng pagkatunaw, na tinitiyak ang malinis na hangin sa paligid ng mga lugar na may mataas na temperatura ng furnace.

Binabawasan ang alikabok at pinong particulate matter na nabuo sa panahon ng pagbuo at paghubog ng mga produktong salamin, na pumipigil sa kontaminasyon at pagpapahusay ng integridad ng produkto.

Regulatory Landscape para sa Dust Control |

|---|

Pagsunod sa Mga Pamantayan ng Air Quality |

Pagsunod sa Kalusugan at Kaligtasan ng Manggagawa |

Pag-iwas sa Panganib sa Sunog at Pagsabog |

Pagsunod sa Pangangalaga sa Kapaligiran |

Real-Time na Pagsubaybay sa Emisyon |

Panlaban sa init at kaagnasan |

Pinababang Downtime at Mga Gastos sa Pagpapanatili |

Kalidad at Pagkakatugma ng Produkto |

Pagtitipid sa Gastos sa Operasyon |

Mga Hamon sa Pagkontrol ng Alikabok sa Industriya ng Salamin |

|---|

Mataas na Pagbuo ng Alikabok |

Init at Kinakaagnasan na kapaligiran |

Mga Panganib sa Kaligtasan ng Manggagawa |

Mga Panganib sa Pagkasunog at Pagsabog |

Pagpapanatili ng Kalidad at Kadalisayan ng Produkto |

Kontaminasyon ng Produkto |

Pagsuot at Pagpunit ng Kagamitan |

Fumes at Gaseous Emissions |

Cross-Contamination |

Mga Pangunahing Pagsasaalang-alang para sa Mabisang Pagkontrol ng Alikabok |

|---|

Mahusay na Pagkuha ng Alikabok at Fume |

Paglaban sa Kemikal at init |

Na-optimize na Airflow at Pamamahala ng Presyon |

Advanced na Mga Materyales sa Pagsala |

Routine Maintenance at Inspeksyon |

Pagsunod sa Regulatory Standards |

Na-customize na Mga Solusyon sa Pagsala |

Pagbabawas ng Panganib para sa Mga Mapanganib na Kemikal |

Mga Flexible na Configuration ng System |

Kumonekta sa amin para sa Expert Consultation

I-explore ang Iba Naming Serbisyo!

Mga Madalas Itanong

Ang paggawa ng salamin ay bumubuo ng malaking halaga ng pinong, abrasive na alikabok—lalo na ang mga particle na mayaman sa silica- sa panahon ng paghawak ng mga hilaw na materyales tulad ng buhangin, soda ash, limestone, at cullet. Ang mga particle na ito ay nagdudulot ng malubhang panganib sa kalusugan tulad ng silicosis at mga isyu sa paghinga. Tinitiyak ng epektibong pagsasala ang kaligtasan ng manggagawa, pinipigilan ang pagsusuot ng kagamitan, pinapanatili ang kadalisayan ng produkto, at pinapagana ang pagsunod sa mga regulasyon sa kapaligiran na nangangailangan ng kahusayan sa pagkuha ng hanggang 99.9%

Ang alikabok mula sa pagdurog at paghawak ng salamin ay labis na nakasasakit at chemically inert, habang ang silica content ay ginagawa itong carcinogenic sa mga mikroskopikong laki. Ang cullet dust ay napaka-irregular at abrasive, nagpapabilis sa pagkasuot ng filter media at nangangailangan ng matibay na disenyo ng inlet, heavy-duty hopper, at air flow management upang maiwasan ang mabilis na pagkasira ng mga filter bag o cartridge .

Ang mga pasilidad ng salamin ay karaniwang gumagamit ng mga filter ng tela (mga baghouse) upang makamit ang mataas na kahusayan na kontrol ng particulate. Sa mga application na kinasasangkutan ng mataas na temperatura o mabigat na silica abrasiveness, maaaring mas gusto ang matibay na mga sistema ng baghouse na may media na lumalaban sa abrasion o mga collector na uri ng cartridge. Para sa mga prosesong bumubuo ng mga acid gas o pabagu-bago ng isip, maaaring kailanganin ang mga karagdagang wet scrubber.