Industrial Baghouse Filter Systems

for Cement & Mineral Plants

Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

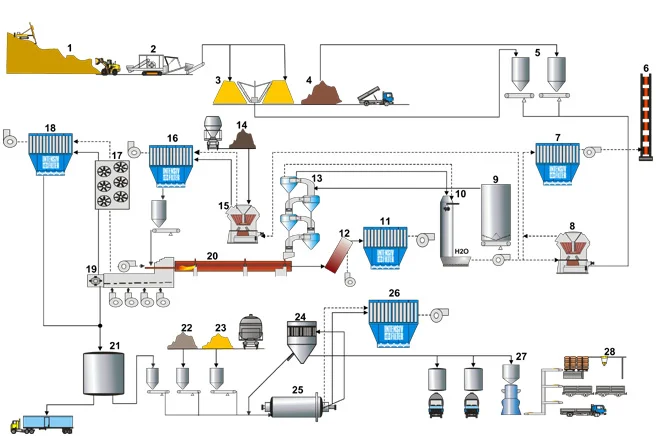

Bag Filters Use Cases in Cement Production Process

Panlabas na filter

Spray dryer

CIP filter

Panlabas na fluidized na kama

Pagpupuno

- 1. Quarry

- 2. Halaman ng pandurog

- 3. homogenization ng hilaw na materyal

- 4. Pinagsasama-sama

- 5. Raw mill feeding silo

- 6. Pangunahing stack

- 7. Bag filter para sa kiln-/raw mill

- 8. Vertical raw mill

- 9. Raw material feeding silo

- 10. Gas conditioning tower

- 11. Bag filter para sa alkali bypass

- 12. Bypass mixing chamber

- 13. Pre-heater ng bagyo

- 14. Hilaw na karbon

- 15. Vertical coal grinding mill

- 16. Bag filter para sa coal grinding plant

- 17. Panlamig na pantubo

- 18. Bag filter para sa clinker cooler

- 19. Palamig ng klinker

- 20. Rotary kiln

- 21. Klinker silo

- 22. Gypsum

- 23. Mineral

- 24. Separator

- 25. Cement finish mill

- 26. Bag filter para sa cement finish mill

- 27. Planta ng packaging

- 28. planta ng Palletization

Kinakailangang Pagtutukoy

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Karaniwang data ng disenyo | Kiln-/raw mill |

|---|---|

Dami ng gas | < 1,200,000 |

Temperatura ng gas | 85 – 110 tambalan / < 250 direkta |

Uri ng alikabok | CaCO3, CaO |

Ang natitirang nilalaman ng alikabok | < 550 |

Hilaw na nilalaman ng alikabok ng gas | < 10 |

Paglilinis | online / offline |

Filter medium | PEA, NX, PPS, PI, GL/PTFE |

Karaniwang data ng disenyo | Alkali bypass |

|---|---|

Dami ng gas | < 800,000 |

Temperatura ng gas | < 250 |

Uri ng alikabok | CaCO3, CaO, Alkali |

Ang natitirang nilalaman ng alikabok | < 25 |

Hilaw na nilalaman ng alikabok ng gas | < 10 |

Paglilinis | offline |

Filter medium | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Karaniwang data ng disenyo | gilingan ng karbon |

|---|---|

Dami ng gas | < 450,000 |

Temperatura ng gas | 80 – 110 |

Uri ng alikabok | uling |

Ang natitirang nilalaman ng alikabok | < 250 |

Hilaw na nilalaman ng alikabok ng gas | < 10 |

Paglilinis | online |

Filter medium | PEA / PAN |

Karaniwang data ng disenyo | Tubular na palamigan |

|---|---|

Dami ng gas | < 1,600,000 |

Temperatura ng gas sa | 250 – 350 |

Lumabas ang temperatura ng gas | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Karaniwang data ng disenyo | Palamig ng klinker |

|---|---|

Dami ng gas | < 800,000 |

Temperatura ng gas | 120 – 180 |

Uri ng alikabok | Klinker |

Hilaw na nilalaman ng alikabok ng gas | 10 – 30 |

Ang natitirang nilalaman ng alikabok | < 10 |

Paglilinis | online |

Filter medium | PE / NX /PI |

Karaniwang data ng disenyo | Paggiling ng semento |

|---|---|

Dami ng gas | < 300,000 |

Temperatura ng gas | 80 – 110 |

Uri ng alikabok | Semento, slag |

Hilaw na nilalaman ng alikabok ng gas | < 350 |

Ang natitirang nilalaman ng alikabok | < 10 |

Paglilinis | online / offline |

Filter medium | PE / PEA |

Our Baghouse Filter Application for the Cement and Minerals

Kinokontrol ang alikabok na nabuo mula sa mga proseso ng pagdurog at paggiling na may mataas na enerhiya, na kumukuha ng pinong particulate matter upang pigilan itong makatakas sa kapaligiran.

Binabawasan ang mga emisyon mula sa mga proseso ng hurno kung saan pinainit ang mga hilaw na materyales, kinokontrol ang alikabok at iba pang mga particle na nasa hangin na inilabas sa panahon ng paggawa ng semento.

Kinukuha ang alikabok habang dinadala ang maramihang materyales, tulad ng limestone at klinker, upang maiwasan ang paglabas ng particle sa mga yugto ng imbakan at paghahatid.

Pinaliit ang mga paglabas ng alikabok sa mga lugar ng packaging at imbakan ng produkto, na tinitiyak na ang mga natapos na produkto ay nakaimpake at nakaimbak sa isang kapaligirang walang kontaminant.

Regulatory Landscape para sa Dust Control |

|---|

Mga Pamantayan sa Kalidad ng Hangin |

Kalusugan at Kaligtasan ng Manggagawa |

Pag-iwas sa Sunog at Pagsabog |

Pangangalaga sa Kapaligiran |

Pagsubaybay at Pag-uulat ng Emisyon |

Kahusayan ng Enerhiya |

Pamamahala ng Basura |

Kalidad at Pagkakapare-pareho ng Produkto |

Pinababang Downtime at Mga Gastos sa Pagpapanatili |

Mga Hamon sa Pagkontrol ng Alikabok |

|---|

Mataas na Antas ng Alikabok |

Mga Panganib sa Kalusugan ng Manggagawa |

Pagsunod sa Kapaligiran |

Mga Panganib sa Sunog at Pagsabog |

Mga Alalahanin sa Kalidad ng Produkto |

Pagsuot at Pagpunit ng Kagamitan |

Cross-Contamination |

Pagsunod sa Kalidad ng Hangin |

Paglago ng Microbial |

Mga Pangunahing Pagsasaalang-alang para sa Mabisang Pagkontrol ng Alikabok |

|---|

Magpatupad ng Mabisang Dust Capture System |

Wastong Airflow at Pressure Control |

Pamamahala ng Temperatura at Halumigmig |

High-Efficiency Filtration System |

Regular na Pagpapanatili at Inspeksyon |

Pagsunod sa Mga Pamantayan sa Industriya |

Madalas na Pagsusuri ng Dust Control System |

Mga Pagbagay na Partikular sa Proseso |

Pagtatasa ng Panganib at Pagbabawas |

Kumonekta sa amin para sa Expert Consultation

I-explore ang Iba Naming Serbisyo!

Mga Madalas Itanong

Sa industriya ng semento, ang mga epektibong solusyon sa pagsasala ay mahalaga para sa pagkontrol ng mga paglabas ng alikabok at pagtiyak ng pagsunod sa kapaligiran. Kasama sa mga karaniwang ginagamit na sistema ng pagsasala ang mga baghouse na filter, na gumagamit ng mga bag ng filter ng tela upang makuha ang mga pinong particle mula sa iba't ibang proseso tulad ng mga tapahan, gilingan, at paghawak ng materyal. Ang mga filter na ito ay pinapaboran para sa kanilang mataas na kahusayan sa pag-alis ng particulate matter. Bukod pa rito, ang mga advanced na solusyon sa pagsasala, tulad ng mga inaalok ng Micronics, ay idinisenyo upang matugunan ang mga natatanging pangangailangan ng industriya ng semento, na tinitiyak ang pagsunod sa mga regulasyon sa kapaligiran at pagpapahusay ng kahusayan sa pagpapatakbo.

Pinapabuti ng mga sistema ng pagsasala ang kahusayan sa paggawa ng semento sa pamamagitan ng epektibong pagkuha ng alikabok at particulate matter, pagbabawas ng pagkasuot ng kagamitan at pagpigil sa mga bara. Tinitiyak nito ang maayos na operasyon, pinapaliit ang downtime, at pinapahusay ang kalidad ng produkto sa pamamagitan ng pagpigil sa kontaminasyon. Nakakatulong din ang wastong pagkontrol sa alikabok na mapanatili ang pagsunod sa regulasyon, na binabawasan ang panganib ng mga multa at mga isyu sa kapaligiran. Bukod pa rito, ang mga mahusay na sistema ng pagsasala ay nakakatulong sa pagtitipid ng enerhiya sa pamamagitan ng pag-optimize ng airflow at pagbabawas ng mga pagbaba ng presyon sa system.

Ang mga advanced na sistema ng pagsasala sa paggawa ng semento ay nakakatulong na mabawasan ang polusyon sa hangin sa pamamagitan ng pagkuha ng mga pinong dust particle at pagliit ng mga emisyon ng mga nakakapinsalang pollutant. Pinapabuti nila ang kalidad ng hangin, tinitiyak ang pagsunod sa mga regulasyon sa kapaligiran at binabawasan ang carbon footprint ng industriya. Sa pamamagitan ng pagpapahusay ng pagkontrol sa alikabok, ang mga sistemang ito ay nakakatulong din sa kalusugan at kaligtasan ng manggagawa. Bukod pa rito, sinusuportahan nila ang sustainability sa pamamagitan ng pagpapagana ng pagbawi at muling paggamit ng mga hilaw na materyales, pagbabawas ng basura, at pag-optimize ng energy efficiency sa mga proseso ng pagmamanupaktura ng semento.