Why Baghouse Filters Are Ideal for Cement and Mineral Plants ?

Bag Filters Use Cases in Cement Production Process

Filtro exterior

Secador por aspersión

Filtro CIP

Lecho fluidizado externo

Relleno

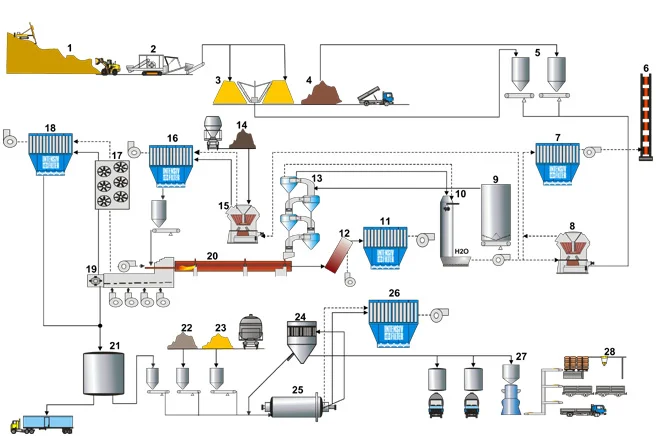

- 1. Cantera

- 2. Planta trituradora

- 3. Homogeneización de la materia prima

- 4. Agregados

- 5. Silo de alimentación del molino de crudo

- 6. Pila principal

- 7. Filtro de mangas para horno/molino de crudo

- 8. Molino de crudo vertical

- 9. Silo de alimentación de materia prima

- 10. Torre de acondicionamiento de gas

- 11. Filtro de bolsa para derivación de álcali

- 12. Cámara de mezcla de derivación

- 13. Precalentador ciclónico

- 14. Carbón crudo

- 15. Molino de carbón vertical

- 16. Filtro de mangas para planta de molienda de carbón

- 17. Enfriador tubular

- 18. Filtro de mangas para enfriador de clínker

- 19. Enfriador de clínker

- 20. Horno rotatorio

- 21. Silo de clínker

- 22. Yeso

- 23. Minerales

- 24. Separador

- 25. Molino de acabado de cemento

- 26. Filtro de mangas para molino de acabado de cemento

- 27. Planta de envasado

- 28. Planta de paletización

Especificación requerida

Kiln & Raw Mill Bag Filter

Alkali Bypass Bag Filter

Datos de diseño típicos | Molino de crudo/horno |

|---|---|

Volumen de gas | < 1.200.000 |

Temperatura del gas | 85 – 110 compuesto / < 250 directo |

Tipo de polvo | CaCO3, CaO |

Contenido de polvo residual | < 550 |

Contenido de polvo de gas crudo | < 10 |

Limpieza | en línea / fuera de línea |

Medio filtrante | PEA, NX, PPS, PI, GL/PTFE |

Datos de diseño típicos | Derivación de álcali |

|---|---|

Volumen de gas | < 800.000 |

Temperatura del gas | < 250 |

Tipo de polvo | CaCO3, CaO, álcali |

Contenido de polvo residual | < 25 |

Contenido de polvo de gas crudo | < 10 |

Limpieza | desconectado |

Medio filtrante | PTFE-PI / GL-PTFE |

Coal Mill Bag Filter

Tubular Cooler Bag Filter

Datos de diseño típicos | Molino de carbón |

|---|---|

Volumen de gas | < 450.000 |

Temperatura del gas | 80 – 110 |

Tipo de polvo | Carbón |

Contenido de polvo residual | < 250 |

Contenido de polvo de gas crudo | < 10 |

Limpieza | en línea |

Medio filtrante | GUISANTE / PAN |

Datos de diseño típicos | Enfriador tubular |

|---|---|

Volumen de gas | < 1.600.000 |

Temperatura del gas en | 250 – 350 |

Temperatura del gas fuera | 120 – 200 |

Clinker Cooler Bag Filter

Cement Finish Mill Bag Filter

Datos de diseño típicos | Enfriador de clínker |

|---|---|

Volumen de gas | < 800.000 |

Temperatura del gas | 120 – 180 |

Tipo de polvo | Escoria de huella |

Contenido de polvo de gas crudo | 10 – 30 |

Contenido de polvo residual | < 10 |

Limpieza | en línea |

Medio filtrante | PE / NX / PI |

Datos de diseño típicos | Molino de acabado de cemento |

|---|---|

Volumen de gas | < 300.000 |

Temperatura del gas | 80 – 110 |

Tipo de polvo | Cemento, escoria |

Contenido de polvo de gas crudo | < 350 |

Contenido de polvo residual | < 10 |

Limpieza | en línea / fuera de línea |

Medio filtrante | Educación física/PEA |

Our Baghouse Filter Application for the Cement and Minerals

Controla el polvo generado por los procesos de trituración y molienda de alta energía, capturando partículas finas para evitar que escapen a la atmósfera.

Reduce las emisiones de los procesos de los hornos donde se calientan las materias primas, controlando el polvo y otras partículas transportadas por el aire que se liberan durante la producción de cemento.

Captura el polvo durante el transporte de materiales a granel, como piedra caliza y clínker, para evitar la liberación de partículas en las etapas de almacenamiento y transporte.

Minimiza las emisiones de polvo en las áreas de embalaje y almacenamiento de productos, garantizando que los productos terminados se empaqueten y almacenen en un entorno libre de contaminantes.

Panorama regulatorio para el control del polvo |

|---|

Normas de calidad del aire |

Salud y seguridad del trabajador |

Prevención de incendios y explosiones |

Protección ambiental |

Monitoreo y reporte de emisiones |

Eficiencia energética |

Gestión de residuos |

Calidad y consistencia del producto |

Reducción de tiempos de inactividad y costos de mantenimiento |

Desafíos del control del polvo |

|---|

Altos niveles de polvo |

Riesgos para la salud de los trabajadores |

Cumplimiento ambiental |

Peligros de incendio y explosión |

Preocupaciones sobre la calidad del producto |

Desgaste del equipo |

Contaminación cruzada |

Cumplimiento de la calidad del aire |

Crecimiento microbiano |

Consideraciones clave para un control eficaz del polvo |

|---|

Implementar sistemas efectivos de captura de polvo |

Control adecuado del flujo de aire y la presión |

Gestión de la temperatura y la humedad |

Sistemas de filtración de alta eficiencia |

Mantenimiento e inspección regulares |

Adherencia a los estándares de la industria |

Evaluación frecuente del sistema de control de polvo |

Adaptaciones específicas del proceso |

Evaluación y mitigación de riesgos |

Conéctese con nosotros para una consulta con expertos

¡Explora nuestros otros servicios!

Preguntas frecuentes

En la industria cementera, las soluciones de filtración eficaces son esenciales para controlar las emisiones de polvo y garantizar el cumplimiento de las normas ambientales. Los sistemas de filtración más comunes incluyen filtros de mangas, que utilizan bolsas de tela para capturar partículas finas de diversos procesos, como hornos, molinos y manipulación de materiales. Estos filtros son populares por su alta eficiencia en la eliminación de partículas. Además, las soluciones de filtración avanzadas, como las que ofrece Micronics, están diseñadas para satisfacer las demandas específicas de la industria cementera, garantizando el cumplimiento de las normativas ambientales y mejorando la eficiencia operativa.

Los sistemas de filtración mejoran la eficiencia en la producción de cemento al capturar eficazmente el polvo y las partículas, reducir el desgaste de los equipos y prevenir obstrucciones. Esto garantiza un funcionamiento fluido, minimiza el tiempo de inactividad y mejora la calidad del producto al prevenir la contaminación. Un control adecuado del polvo también contribuye al cumplimiento normativo, reduciendo el riesgo de multas y problemas ambientales. Además, los sistemas de filtración eficientes contribuyen al ahorro energético al optimizar el flujo de aire y reducir las caídas de presión en el sistema.

Los sistemas avanzados de filtración en la producción de cemento ayudan a reducir la contaminación atmosférica al capturar partículas finas de polvo y minimizar las emisiones de contaminantes nocivos. Mejoran la calidad del aire, garantizando el cumplimiento de la normativa ambiental y reduciendo la huella de carbono de la industria. Al optimizar el control del polvo, estos sistemas también contribuyen a la salud y la seguridad de los trabajadores. Además, promueven la sostenibilidad al permitir la recuperación y reutilización de materias primas, reducir los residuos y optimizar la eficiencia energética en los procesos de fabricación de cemento.