Why Electrostatic Precipitators Matter

Industrial facilities worldwide generate enormous quantities of dust, smoke, and gaseous pollutants every year. According to the International Energy Agency (IEA), power plants and heavy industries account for nearly 35% of global particulate emissions. For cement plants, steel mills, and coal-fired power stations, controlling these emissions is not just about compliance—it is about protecting workers, communities, and the environment while maintaining operational efficiency.

Among the many air pollution control solutions available today, Elektrostatické odlučovače (ESP) stand out due to their scalability, efficiency, and long operational life. Capable of capturing up to 99.9% of fine particulate matter (PM2.5 and below)—including particles as tiny as 0.01 microns—ESPs provide a reliable and future-ready solution for industries that must balance environmental responsibility with performance.

What Is an Electrostatic Precipitator?

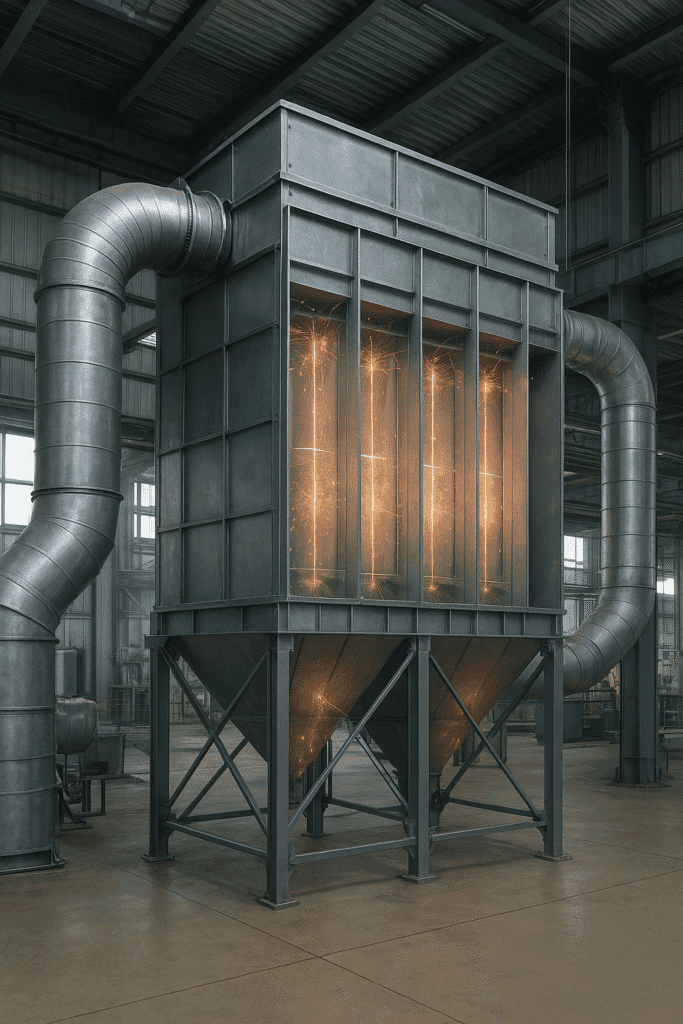

An Electrostatic Precipitator (ESP) is a large-scale air pollution control device that removes fine particles like dust, ash, and smoke from industrial exhaust gases. Unlike filters that physically trap dust, ESPs use electrical energy to charge particles in the flue gas, forcing them to migrate toward oppositely charged plates where they accumulate.

The performance of an ESP is remarkable: they can handle gas volumes ranging from 1,000 m³/h to over 2,000,000 m³/h, achieve a collection efficiency of 95–99.9%, and capture particles as fine as 0.01 microns. This combination of high capacity and microscopic precision makes ESPs indispensable across industries with heavy dust loads.

How Do Electrostatic Precipitators Work?

The working principle of an ESP lies at the intersection of electrical engineering and particle physics. When dust-laden gas enters the chamber, it is carefully guided at low velocity to ensure smooth flow. Inside, electrodes generate a high-voltage DC field of 20–100 kV, creating a corona discharge. This discharge releases ions, which attach themselves to the dust particles in the gas stream.

Once charged, the particles experience an electrostatic force that causes them to migrate toward grounded collector plates. Over time, these particles accumulate in thick layers. To remove them, the ESP uses rapové mechanismy—mechanical hammers or vibrators—that periodically shake the plates, dislodging the dust into hoppers. Finally, the cleaned air exits the system, with emissions reduced to levels that meet stringent global standards.

To put this into perspective, a 500 MW coal-fired power plant equipped with an ESP can process over 1.2 million m³/h of flue gas, capturing more than 100 tons of fly ash every day.

Typy elektrostatických odlučovačů

Electrostatic precipitators (ESPs) come in several types, each engineered to handle specific dust characteristics, gas compositions, and industrial processes. Their selection depends on factors such as particle size, moisture content, corrosiveness, and gas volume.

Dry Electrostatic Precipitators:

The most widely used type, dry Electrostatic Precipitators, is applied in industries such as cement, steel, and power generation. They are highly efficient in removing dry particulates like fly ash, cement dust, and metal oxides, achieving collection efficiencies between 95–99.9%. Their durability, low operating costs, and ability to handle large volumes of flue gas make them the standard choice for heavy industries.

Wet Electrostatic Precipitators:

These units are designed for handling dust that is sticky, corrosive, or has high moisture content—conditions where dry Electrostatic Precipitators may fail. Wet Electrostatic Precipitators are commonly installed in chemical processing plants, smelters, and waste-to-energy facilities. They are often constructed from corrosion-resistant alloys or fiberglass-reinforced plastic (FRP) to withstand aggressive environments. Wet Electrostatic Precipitators are also effective in controlling submicron particles, acid mists, and aerosols.

Plate-Type Electrostatic Precipitators:

Characterized by large, flat collecting plates, these Electrostatic Precipitators can treat enormous gas volumes, often several million cubic meters per hour. They are particularly suited for cement kilns, coal-fired power plants, and industrial boilers where flue gases are generated in massive quantities. Their design supports high efficiency even under continuous heavy-duty operation.

Tubular Electrostatic Precipitators:

Built with cylindrical collecting electrodes, tubular Electrostatic Precipitators are designed for lower gas volumes ranging from 1,000 to 20,000 m³/h. They are commonly used for applications requiring fine mist or tar removal, such as in oil refineries, coke ovens, or small-scale industrial processes. Their compact design makes them ideal for industries where space is limited and gas flow is moderate.

Benefits of Electrostatic Precipitators

The popularity of Electrostatic Precipitators is rooted in their technical superiority and cost-effectiveness. Some of the most significant benefits include:

- Ultra-High Efficiency: Capable of capturing fine dust, PM10, PM2.5, and sub-micron particles.

- Úspora energie: With a pressure drop below 250 Pa, Electrostatic Precipitators consume up to 30% less fan energy than bag filters.

- Škálovatelnost: Adaptable from small chemical plants to mega thermal power projects with gas volumes in the millions of cubic meters per hour.

- Trvanlivost: With regular maintenance, Electrostatic Precipitators can operate reliably for 20–30 years.

- Soulad s předpisy: Easily meet emission standards such as CPCB (<30 mg/Nm³ in India), EPA (<20 mg/Nm³ in the US), and EU (<10 mg/Nm³).

Where Are Electrostatic Precipitators Used?

Electrostatic precipitators are widely adopted across industries where particulate emissions are unavoidable. In cement manufacturing, they capture kiln and cooler dust, reducing particulate matter from levels as high as 1,000 mg/Nm³ to below 30 mg/Nm³. In coal-fired power plants, they capture fly ash with efficiencies of up to 99%, significantly cutting emissions.

The steel and metallurgical industries rely on Electrostatic Precipitators to control emissions from blast furnaces, converters, and sintering plants. In the chemical and petrochemical sector, they are indispensable for handling acid mists, oil vapors, and catalytic cracker emissions. Waste-to-energy facilities also depend on Electrostatic Precipitators to safely filter complex dust compositions, while pulp and paper mills employ them to manage recovery boiler and lime kiln dust.

Limitations to Consider

Despite their efficiency and versatility, Electrostatic Precipitators come with certain operational challenges. Their installation requires a larger footprint, which may not be feasible for space-constrained plants. The initial capital investment is also higher, typically 20–30% more than a bag filter system. Another limitation is dust resistivity; Electrostatic Precipitators perform best when dust resistivity falls within a certain range. Very high or very low resistivity can reduce efficiency and may require additional conditioning.

Maintenance is another factor to consider. Although Electrostatic Precipitators are durable, they require routine inspection of electrodes, insulators, and hoppers to prevent issues such as back corona or re-entrainment of dust. That said, when evaluated over their lifetime, Electrostatic Precipitators remain among the most cost-effective dust collection solutions for large-scale industries.

Intensiv Filter Himenviro: Delivering World-Class ESP Solutions

At Intensiv Filter Himenviro, we specialize in engineering Electrostatic Precipitators that combine German design heritage with modern automation technology. Our systems are designed for demanding industrial environments, capable of handling gas flows of up to 2,000,000 m³/h while achieving 99.9% collection efficiency.

With IoT-enabled monitoring systems, operators can gain real-time insights into performance, enabling predictive maintenance and minimizing downtime. Our Electrostatic Precipitators are fully compliant with global emission standards, including CPCB, EPA, and EU directives, ensuring that our clients remain ahead of evolving environmental regulations.

From cement kilns to power plants, steel mills to chemical industries, Intensiv Filter Himenviro provides tailored ESP solutions that deliver efficiency, reliability, and sustainability.

Závěr

Electrostatic precipitators are more than just dust collectors—they are cornerstones of industrial air pollution control. Their ability to remove fine particulates with up to 99.9% efficiency, combined with low energy consumption and long service life, makes them indispensable for industries facing stricter emission standards.

With Intensiv Filter Himenviro as your partner, you don’t just install an ESP—you invest in a future-ready environmental solution that aligns efficiency with sustainability, ensuring cleaner air for industries and communities alike.

Objevte naši nabídku řešení:

Často kladené otázky

An ESP is an industrial air pollution control device that removes fine particles such as dust, ash, and smoke from exhaust gases. It works by electrically charging particles in the gas stream and collecting them on oppositely charged plates, ensuring clean air is released back into the environment.

When flue gas enters the ESP, high-voltage electrodes create a corona discharge that charges dust particles. These charged particles migrate to grounded collector plates, where they accumulate. Rapping mechanisms periodically dislodge the dust into hoppers for safe disposal, while clean air exits the system.

- Suché elektrostaticky odlučovače (ESP): Used in cement, steel, and power plants for dry particulates like fly ash and metal oxides.

- Mokré elektrostatické odlučovače (ESP): Designed for sticky, corrosive, or moist dust in chemical plants and smelters.

- Deskové elektrostatické odlučovače: Handle large gas volumes, common in power plants and cement kilns.

- Trubkové elektrostatické odlučovače (ESP): Compact units for smaller gas volumes, used in oil refineries and coke ovens.