Офиси

СЕДАЛИЩЕ

Германия

- Интензивен филтър Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Германия - +49 20534200990

РЕГИОНАЛЕН ОФИС

Великобритания

- Интензивен филтър Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Великобритания - +44 1922 628893

РЕГИОНАЛЕН ОФИС

Обединени арабски емирства

- Интензивен филтър Himenviro Technologies FZE – LLC

Бизнес център, Sharjah Publishing City Free Zone, Sharjah, ОАЕ - +971-556074697

РЕГИОНАЛЕН ОФИС

Индия

- Интензивен филтър Himenviro Private Limited

D-247/11, сектор-63, Noida - 201301, Утар Прадеш, Индия - +91-120-4642-500

РЕГИОНАЛЕН ОФИС

Индия

- Интензивен филтър Himenviro Private Limited

D-247/11, сектор-63, Noida - 201301, Утар Прадеш, Индия - +91-120-4642-500

РЕГИОНАЛЕН ОФИС

Индия

- Интензивен филтър Himenviro Private Limited

D-247/11, сектор-63, Noida - 201301, Утар Прадеш, Индия - +91-120-4642-500

Решения за филтриране на въздух и прах в стъкларската промишленост

Стъкларската промишленост се характеризира с високи температури, използване на суровини, които генерират фин прах, и производство на летливи изпарения. Тези фактори представляват значителни рискове за здравето на работниците, спазването на екологичните изисквания и качеството на продуктите. Нашите системи за филтриране на въздух и прах са проектирани специално за стъкларската промишленост, осигурявайки ефективно улавяне на частици, изпарения и газове във въздуха на критични етапи от производството. Нашите решения помагат на производителите да отговарят на регулаторните стандарти, да защитават работниците и да гарантират, че продуктите поддържат високото си качество без замърсяване.

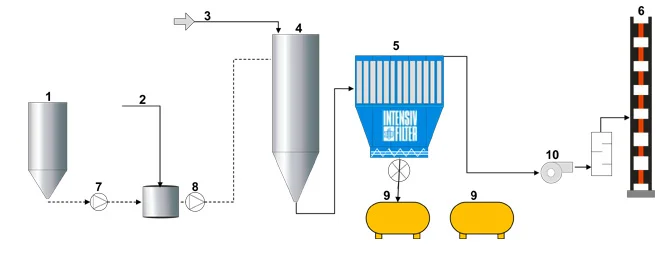

Процес на филтриране на прах в стъкларската промишленост

Филтър за стъкларска пещ

- 1. NaOH резервоар

- 2. Вода

- 3. Горещ газ от стъкленото корито

- 4. Охлаждащ реактор

- 5. Филтър за стъкларска пещ

- 6. Комин

- 7. Дозираща помпа

- 8. Помпа за охлаждане

- 9. Транспортен контейнер

- 10. Предизвикано течение

Необходими спецификации

Типични проектни данни | Пещи за изгаряне на отпадъци |

|---|---|

Обем на газа | 38,000 |

Температура на газа | 180 – 200 |

Вид прах | Натриев сулфат, сода, боракс, кварц |

Съдържание на прах от необработен газ | 10 – 25 |

Съдържание на остатъчен прах | < 10 |

Почистване | офлайн |

Филтърна среда | Полиимид |

Сорбент | Натриев хидроксид |

Приложения за контрол на праха в стъкларската промишленост

Филтрира праха във въздуха по време на обработката и съхранението на суровини като силициев диоксид, калцинирана сода и варовик, като гарантира, че прахът не се разпространява в други части на съоръжението.

Контролира замърсителите във въздуха и частиците, образувани по време на процеса на топене, осигурявайки чист въздух около зоните с висока температура на пещите.

Намалява праха и фините частици, генерирани по време на формоването и леенето на стъклени изделия, предотвратявайки замърсяването и подобрявайки целостта на продукта.

Регулаторен пейзаж за контрол на праха |

|---|

Съответствие със стандартите за качество на въздуха |

Съответствие с изискванията за здраве и безопасност на работниците |

Предотвратяване на опасност от пожар и експлозия |

Съответствие с изискванията за опазване на околната среда |

Мониторинг на емисиите в реално време |

Устойчивост на топлина и корозия |

Намалени разходи за престой и поддръжка |

Качество и постоянство на продукта |

Спестявания на оперативни разходи |

Предизвикателства пред контрола на праха в стъкларската промишленост |

|---|

Високо ниво на прах |

Топлинна и корозивна среда |

Рискове за безопасността на работниците |

Опасности от горене и експлозия |

Поддържане на качеството и чистотата на продукта |

Замърсяване на продукта |

Износване на оборудването |

Изпарения и газови емисии |

Кръстосано замърсяване |

Ключови съображения за ефективен контрол на праха |

|---|

Ефективно улавяне на прах и изпарения |

Химическа и топлоустойчивост |

Оптимизирано управление на въздушния поток и налягането |

Усъвършенствани филтрационни материали |

Рутинна поддръжка и инспекции |

Съответствие с регулаторните стандарти |

Персонализирани решения за филтриране |

Смекчаване на риска от опасни химикали |

Гъвкави системни конфигурации |

Свържете се с нас за експертна консултация

Разгледайте другите ни услуги!

Често задавани въпроси

Производството на стъкло генерира значителни количества фин, абразивен прах – особено богати на силициев диоксид частици – по време на обработката на суровини като пясък, калцинирана сода, варовик и стъклени трошки. Тези частици представляват сериозни рискове за здравето, като силикоза и респираторни проблеми. Ефективната филтрация гарантира безопасността на работниците, предотвратява износването на оборудването, поддържа чистотата на продукта и позволява спазване на екологичните разпоредби, изискващи ефективност на улавяне до 99.9%.

Прахът от трошене и обработка на стъкло е изключително абразивен и химически инертен, докато съдържанието на силициев диоксид го прави канцерогенен при микроскопични размери. Прахът от стъкло е силно неравномерен и абразивен, което ускорява износването на филтърните среди и налага здрава конструкция на входа, тежки бункери и управление на въздушния поток, за да се предотврати бързото разграждане на филтърните торби или патрони.

В стъкларските предприятия обикновено се използват тъканни филтри (ръкавни филтри), за да се постигне високоефективен контрол на частиците. В приложения, включващи високи температури или силна абразивност на силициев диоксид, може да се предпочетат издръжливи системи с ръкавни филтри с устойчива на абразия среда или колектори тип патрон. За процеси, генериращи киселинни газове или летливи емисии, може да са необходими допълнителни мокри скрубери.