In an era of tightening emissions regulations and an increased focus on sustainable industrial practices, selecting the right dust collection technology is a mission-critical decision. At فلتر مكثف هيمنفيرو, with a legacy of over 100 years in clean air technology and more than 70,000 installations worldwide, we are committed to helping industries across sectors—from cement and steel to food, chemicals, and power generation—achieve operational excellence with proven filtration solutions.

Two of the most widely adopted technologies in dust control systems today are the Reverse Air Bag House (RABH) و ال Electrostatic Precipitator (ESP). This article compares these systems from a technical and practical standpoint to help you make an informed, future-ready decision.

Understanding the Technologies

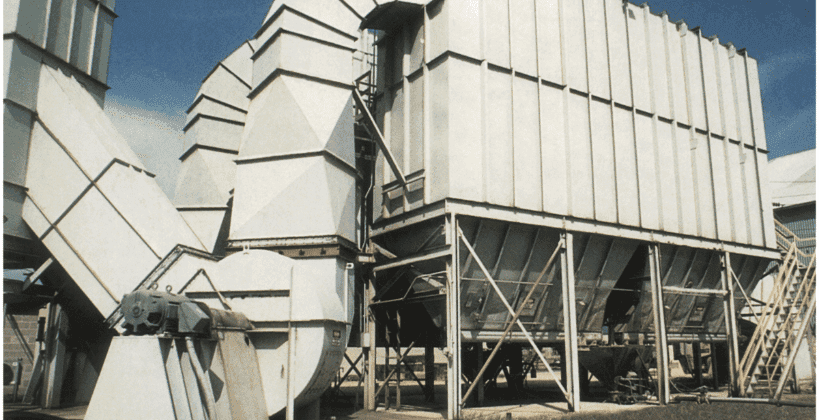

Reverse Air Bag House (RABH)

The Reverse Air Bag House is a high-efficiency fabric filtration system engineered to operate under extreme process conditions. It uses high-performance filter bags to capture dust particles, which are periodically cleaned by gentle reverse airflow, ensuring long filter life and consistent performance.

How it works:

Dirty gas enters the chamber and passes through fabric filter bags that capture even submicron particles. A reverse flow of clean air is then pulsed through the bags to dislodge the dust cake, which falls into the hopper for discharge.

High dust loads

Variable gas conditions

Fine and sticky dust particles

Submicron particulate removal

Electrostatic Precipitator (ESP)

An ESP utilizes an electric field to charge and capture dust particles on collection plates. As flue gas flows through the system, particles are ionized and attracted to electrodes, then periodically dislodged by mechanical rapping into hoppers.

How it works:

Gas enters the ESP, where high-voltage electrodes ionize the particles. These charged particles are drawn to collecting plates, which are rapped intermittently to dislodge dust into collection hoppers.

Ideal for:

High-volume gas flow

Uniform dust loading

Medium- to high-temperature applications

Large-scale power generation and smelting

Technical Comparison

ميزة | منزل الوسادة الهوائية العكسية | المترسب الكهروستاتيكي |

|---|---|---|

Particulate Removal Efficiency | Up to 99.9% (excellent for PM₂.₅ and below) | 95–99.5% (less effective for fine dust <2 microns) |

Dust Type Compatibility | Handles all types, including high-resistivity and sticky dust | Performance sensitive to dust resistivity |

Temperature Handling | Up to 250°C (custom options available) | 160–400°C |

صيانة | Modular and easily accessible, simple bag replacement | Complex, requires expertise to maintain the HV system and rapping mechanism |

استهلاك الطاقة | Low (uses low-pressure reverse air) | Moderate to high (needs HV power) |

متطلبات المساحة | Compact, modular design | Larger footprint for equivalent capacity |

CapEx / OpEx | Moderate initial cost, lower total ownership cost | High initial cost, higher long-term maintenance |

Application Insights from Intensiv Filter Himenviro

With our strong presence in diverse industries and over a century of expertise, Intensiv Filter Himenviro understands how dust behaves in real industrial environments. Here’s how we guide our clients:

Choose RABH when:

- You’re in the cement, food, chemical, or pharma industry, where emissions need to be below 10 mg/Nm³.

- Your dust has high resistivity, is sticky, or highly variable.

- You’re looking to upgrade from ESP to bag filter for better compliance.

- Space is limited and maintenance needs to be streamlined.

Choose ESP when:

- You manage high gas volumes, such as in coal-based power plants or metal smelters.

- Dust properties are stable, and resistivity is favorable.

- Installation space is available, and you require low-pressure drop systems.

What Makes Intensiv Filter Himenviro the Right Partner?

At Intensiv Filter Himenviro, we don’t just manufacture air pollution control systems—we engineer customized, high-efficiency solutions backed by German technology, global experience, and in-house R&D.

Why Choose Us:

- In-house manufacturing and engineering for maximum quality control.

- German precision in design, process, and system integration.

- More than 100 years of experience in managing over 200 dust types.

- Global presence with successful installations in over 110 countries.

- Specialized upgrades: from ESP refurbishments to ESP-to-baghouse conversions.

خاتمة

Both Reverse Air Bag Houses and Electrostatic Precipitators are proven technologies. The decision should be driven by your dust characteristics, process temperature, space availability, and emission targets.

If you’re striving for long-term performance, low emissions, and energy efficiency—especially in industries with challenging dust properties—the Reverse Air Bag House from Intensiv Filter Himenviro stands out as the superior solution. For high-volume and temperature-stable processes, our expertly designed ESPs still deliver unmatched scalability.