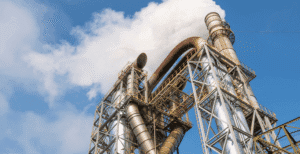

In an era where sustainability and environmental compliance define corporate responsibility, managing stack emissions has emerged as a priority for industries worldwide. Stack emissions refer to the gases and particulates released into the atmosphere through smokestacks or flues in industrial facilities. These emissions are the byproducts of fuel combustion, chemical reactions, and other industrial processes.

From power generation to cement production, industries release a mix of harmful pollutants—each with distinct characteristics, environmental impacts, and health consequences. Understanding the nature of these emissions and how to control them efficiently is key to ensuring environmental protection and regulatory compliance.

What Are Stack Emissions?

Stack emissions are generated from industrial operations that involve combustion, heating, or processing of raw materials. The exhaust gases released through stacks may contain various air pollutants depending on the fuel type and operational conditions. While the composition can vary, the most common pollutants include particulate matter (PM), sulfur dioxide (SO₂), nitrogen oxides (NOₓ), carbon monoxide (CO), carbon dioxide (CO₂), and volatile organic compounds (VOCs).

Each of these pollutants presents unique challenges. Particulate matter can penetrate deep into human lungs, causing respiratory ailments. SO₂ and NOₓ contribute to acid rain and smog, while CO is a toxic gas that can be fatal in high concentrations. CO₂, though not immediately harmful to health, is a significant greenhouse gas and a key contributor to climate change.

Importance of Controlling Stack Emissions

Khám phá các giải pháp của chúng tôi:

Key Pollutants and Their Sources

Methods to Control Stack Emissions

Role of Continuous Monitoring

Challenges in Stack Emission Control

Environmental and Economic Benefits

From an environmental perspective, lower emissions mean better air quality, healthier ecosystems, and reduced contribution to climate change. For industries, it means achieving environmental certifications such as ISO 14001, improving corporate image, and increasing customer trust.