In Germany’s highly competitive and regulated industrial environment, operational success is no longer defined solely by production capacity or output quality. It is increasingly measured by how efficiently, sustainably, and cleanly production is achieved. With rising energy prices, tightening environmental laws, and aggressive climate goals set for 2030 and beyond, industrial enterprises are undergoing a shift that extends across key sectors such as cement, steel, chemicals, pharmaceuticals, and energy generation.

One major transformation is clear: filter modernization is no longer optional. It is now a strategic business decision—vital to ensuring regulatory compliance, operational efficiency, cost control, and long-term competitiveness.

Tại Intensiv-Filter Himenviro, we have been at the forefront of this movement, supporting German and global manufacturers with tailored solutions for modernizing outdated filtration and dust extraction systems. In this article, we outline why modernization is accelerating and how it impacts your plant’s bottom line and regulatory positioning.

1. Regulatory Compliance: Responding to Increasingly Stringent Norms

Germany is home to some of the world’s most advanced and stringent environmental regulations. Industrial facilities, especially in dust-intensive sectors like cement manufacturing, metallurgy, and biomass energy, are now required to meet total particulate matter emission limits as low as 10 mg/Nm³. This shift is driven by public health concerns, climate objectives, and international sustainability frameworks.

With regulatory authorities ramping up real-time monitoring requirements, performing frequent audits, and introducing substantial fines—often up to €50,000 per violation—compliance is not just a legal necessity, but a reputational and operational one.

Unfortunately, many installed filtration systems—including legacy electrostatic precipitators (ESPs), outdated baghouses, or mechanical scrubbers—are 20 to 30 years old and no longer capable of delivering the precision filtration needed under today’s regulatory frameworks.

Modernization ensures:

Continuous emissions monitoring capability

Lower and more consistent particulate output

Automated performance logging and diagnostics for audit-ready reporting

2. Energy Efficiency: Reducing Operational Costs Amid Soaring Power Prices

German industries face some of the highest industrial electricity costs in Europe, typically ranging between €0.20 and €0.25 per kWh. In filtration systems, energy consumption from fans, compressors, and cleaning mechanisms can account for a significant portion of plant overhead.

- Modern filtration technology directly addresses this burden through multiple innovations. For instance:

- Low-pressure reverse air systems reduce the need for compressed air, slashing cleaning-related energy use.

- Hybrid filters reduce the pressure drop, lowering the fan energy requirement.

- Variable frequency drives (VFDs) and automation allow for dynamic control of fans and compressors, preventing unnecessary load cycles.

In one recent project, Intensiv-Filter Himenviro retrofitted a cement plant in western Germany with a next-generation bag filter system. The results were measurable and immediate:

MỘT 27% reduction in energy usage related to dust collection

MỘT 9-month payback period on investment through energy cost savings alone

3. Uptime and Reliability: Avoiding Costly Shutdowns and Maintenance Burdens

Downtime—especially unplanned—is a critical challenge in continuous manufacturing environments. In many plants, filtration equipment is one of the main sources of reliability concerns due to:

Bag breakage from excessive pressure

Dust re-entrainment and clogging

Inconsistent cleaning cycles

Poor filtration media compatibility with process temperatures or chemistry

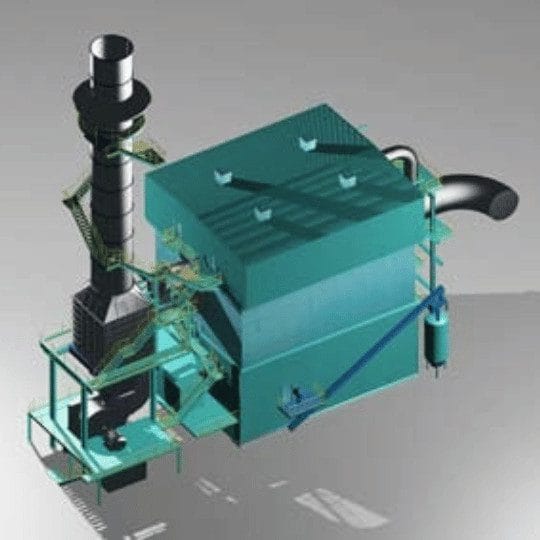

Upgrading to modern filter technology changes this narrative. At Intensiv-Filter Himenviro, we employ:

Modular filter designs for faster maintenance and minimal downtime

Smart diagnostic systems for predictive maintenance and real-time issue detection

- High-performance filter media, including PTFE and ePTFE-membrane fabrics, for longer service life in high-temperature or chemically aggressive environments

Up to 5 times longer filter life

80% reduction in maintenance hours and costs

- Consistently low and stable pressure drop values, ensuring efficient system performance

4. ESG and Sustainability Goals: Driving Real Change Beyond Compliance

Germany’s industrial roadmap calls for a 55% reduction in CO₂ emissions by 2030. While dust collectors themselves are not direct carbon emitters, the systems contribute significantly to material recovery, waste reduction, and process energy efficiency—all vital components of an effective ESG strategy.

Modern filtration systems help manufacturers:

Recover valuable raw materials such as lime, clinker dust, or metal fines for reuse, reducing virgin material input

Extend filter life and reduce waste disposal volume

Provide automated emissions tracking and logging for transparent sustainability reporting

5. Global Market Demands: Aligning with Export and Supply Chain Requirements

Germany’s status as a global manufacturing powerhouse is tied to its ability to meet international environmental benchmarks. Whether supplying parts to OEMs or exporting end products, compliance with environmental protocols is becoming a non-negotiable requirement.

Modern filtration systems enable German producers to:

Comply with EU BAT and other international standards

Achieve ISO 14001 (Environmental Management) Và ISO 50001 (Energy Management) certifications

Meet sustainability and emissions targets required by leading global buyers

6. Field-Proven Modernization Projects Across Germany

Case Study: ESP to “EcoJet” Bag Filter – Cement Kiln Retrofit

A cement kiln in Germany faced non-compliance issues due to underperforming ESPs. Intensiv-Filter Himenviro engineered a conversion to the EcoJet Bag Filter System, a high-efficiency hybrid design.

Achieved full compliance with current cement kiln emissions limits

Enhanced reliability through high-performance pulse-jet cleaning

Case Study: Steel Works HKM – Offline Double-Row Filter

A major steel manufacturer experienced reduced uptime due to dust load challenges. IFH implemented an offline cleaning, double-row bag filter system.

- Maximized uptime by isolating sections during cleaning

- Delivered stable operation in a high-dust, high-temperature environment

7. Why Intensiv-Filter Himenviro is the Partner of Choice

With over a century of filtration expertise, we bring unmatched depth in engineering design, material science, and operational know-how. Our track record includes:

50,000+ successful installations across 110+ countries

Specialized solutions for cement, steel, chemicals, pharma, and power

Advanced product portfolio: from hybrid filters ĐẾN low-pressure reverse air systems

Fully integrated services: site assessment, engineering, fabrication, installation, and lifecycle support

Our commitment goes beyond providing equipment. We offer turnkey modernization programs that align filtration systems with each client’s operational, regulatory, and sustainability goals.

Final Thoughts: Modernization is an Investment in Your Future

In the face of rising energy costs, increasingly complex regulations, and heightened sustainability expectations, dust and gas filtration systems are emerging as strategic assets, not background utilities.

Forward-thinking manufacturers are prioritizing modernization not because they are forced to, but because the return on investment is immediate, measurable, and long-term. From reducing emissions and energy costs to improving uptime and ESG scores, the benefits are clear.

Ready to Begin Your Modernization Journey?

Let’s assess your current system and plan for the future.

Request a customized performance evaluation and ROI estimate

Explore our project references specific to your industry

Connect with our engineering team for a technical consultation