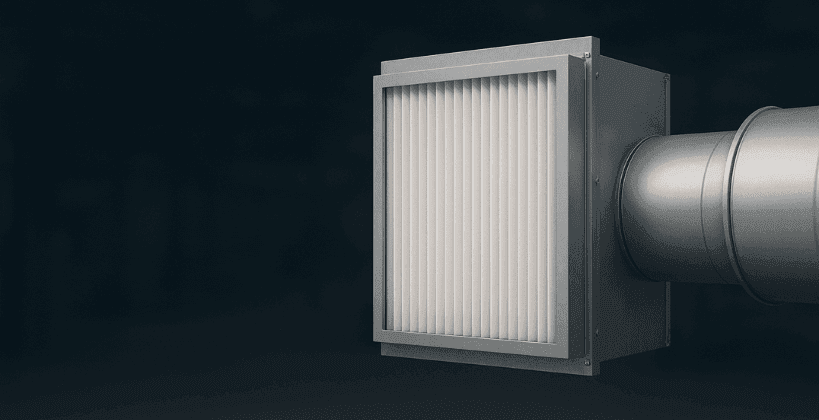

Not all industrial air filters are created equal. The bigger question is—is your current system truly designed for your industry’s challenges?

Air quality is not just a compliance requirement—it’s a business-critical factor that impacts productivity, worker safety, product quality, and overall profitability. Different industries deal with vastly different contaminants. Cement plants fight abrasive dust and scorching heat. Food processors battle allergens and hygiene risks. Pharmaceutical manufacturers must uphold sterility at microscopic levels.

Using a generic, one-size-fits-all filtration solution can backfire. It often leads to higher operating costs, reduced efficiency, and potential regulatory violations. On the other hand, a system tailored to your specific industry ensures cleaner air, higher uptime, and long-term cost savings.

Tại Intensiv-Filter Himenviro, we specialize in custom-engineered industrial filtration systems designed to match the unique demands of each sector. Let’s explore how the right choice makes all the difference.

Tổng quan về sản phẩm

Cement Industry: Managing Heavy Dust Loads and High Temperatures

Cement manufacturing ranks among the most demanding industrial environments. From kilns and clinker coolers to grinders and material handling units, every stage of production generates extremely high dust concentrations. This fine, abrasive dust doesn’t just pose environmental concerns—it accelerates equipment wear, clogs systems, and drives up unplanned maintenance costs. On top of that, plants must contend with elevated process temperatures, making filtration even more challenging.

Giải pháp: Advanced baghouse filters designed with abrasion-resistant fabrics and high-temperature capabilities ensure effective dust capture while maintaining airflow efficiency, even in the harshest conditions.

Value: By preventing excessive dust accumulation, these systems protect downstream equipment, extend the service life of critical components, and reduce unscheduled downtime. The result is stable production, lower maintenance costs, and improved workplace safety—all while ensuring compliance with stringent environmental regulations.

Food and Beverage Industry: Hygiene and Cross-Contamination Prevention

In the food and beverage sector, air quality directly impacts product safety and consumer trust. Even the smallest airborne particles—such as allergens, spores, or fine dust—can compromise purity, alter taste, or lead to contamination incidents. For producers, this not only threatens brand reputation but also risks costly recalls and legal penalties. To prevent such risks, regulatory authorities worldwide enforce strict hygiene standards, making air filtration an essential part of compliance and quality assurance.

Giải pháp: Hygienic filters constructed with FDA-approved materials and designed for easy integration with CIP (Clean-in-Place) systems ensure reliable performance while simplifying cleaning and maintenance. Their design minimizes dead zones where contaminants can accumulate, supporting continuous operations in sensitive production environments.

Value: These advanced systems safeguard product integrity, reduce cross-contamination risks between batches, and guarantee adherence to global food safety certifications such as HACCP, ISO 22000, and FSSAI. The result is greater consumer confidence, uninterrupted production, and a stronger competitive edge in demanding markets.

Pharmaceutical Industry: Cleanroom and Sterility Requirements

Pharmaceutical manufacturing demands some of the most stringent air quality controls in the world. Even microscopic particles, airborne bacteria, or trace contaminants can compromise entire batches of high-value medicines—leading to significant financial losses and reputational risks. To prevent this, production facilities must meet strict cleanroom classifications and regulatory guidelines, ensuring air purity that supports sterility at every stage of production.

Giải pháp: Intensiv-Filter Himenviro provides custom-engineered filtration systems designed specifically for pharmaceutical applications. Built with high-efficiency filter media and precision-sealed housings, these systems control particulate matter and microbial contaminants while supporting the pressure stability and airflow uniformity required for cleanroom environments.

Value: Our solutions help pharmaceutical companies maintain sterility, streamline compliance with global regulations such as EU GMP and US FDA, and safeguard product integrity. This not only ensures patient safety but also builds long-term trust with healthcare providers and regulatory bodies worldwide.

Selection Factors: Key Decision-Making Criteria

When selecting an industrial air filter system, the initial price tag should not be the only deciding factor. A poorly chosen system can lead to recurring downtime, high maintenance costs, and non-compliance penalties. Instead, consider these essential criteria:

- Contaminant Type: Dust, fumes, volatile organic compounds (VOCs), or microorganisms each require specialized filtration.

- Airflow Volume: Facilities with large-scale operations need systems capable of handling millions of Nm³/h without performance losses.

- Môi trường hoạt động: High humidity, chemical corrosion, or extreme temperatures demand advanced engineering.

- Particle Size Requirements: Some industries must capture particles as small as 0.01 microns.

- Tuân thủ quy định: From CPCB and EPA to FDA and EU GMP, compliance frameworks dictate filter design and efficiency levels.

Advantages of Intensiv-Filter Himenviro Industrial Air Filters

By choosing Intensiv-Filter Himenviro, you invest in more than just a filtration system—you gain a long-term partner in efficiency, compliance, and sustainability. Our air filters are not off-the-shelf products; they are engineered solutions designed to withstand the toughest industrial conditions while delivering measurable value year after year.

- Tailored Solutions for Every Industry:

Each industry faces unique challenges, whether it’s abrasive cement dust, stringent hygiene in food processing, or ultra-clean air requirements in pharmaceuticals. Our filters are customized to meet those exact demands, ensuring maximum efficiency and reliability. - Proven Performance Across Applications:

Our systems have consistently delivered results in dust-heavy environments, sterile cleanrooms, and sensitive food-grade applications. This track record of performance builds trust with industries worldwide, giving you confidence in continuous uptime and compliance. - Long-Term Operational Savings:

Beyond capturing contaminants, our filters are designed to lower your total cost of ownership. Reduced downtime, extended equipment life, and lower maintenance needs translate into significant cost savings and stronger ROI over time. - Globally Benchmarked Standards:

Built to meet and exceed international regulatory requirements such as EPA, CPCB, FDA, and EU GMP, our solutions guarantee not only compliance but also long-term sustainability. They help industries cut emissions, optimize energy use, and enhance workplace safety.

In short, Intensiv-Filter Himenviro systems don’t just clean the air—they protect your people, your processes, and your profits.

Why the Right Filter Protects More Than Air Quality

Air filtration today goes far beyond environmental compliance—it has become a strategic investment for long-term business success. The right filtration system directly impacts worker safety by reducing exposure to harmful particles, while also enhancing the overall work environment. A cleaner workplace not only boosts productivity but also minimizes health risks, ensuring companies meet strict occupational safety standards.

Beyond protecting people, advanced filtration solutions play a critical role in preserving equipment and product quality. By preventing dust-related wear and ensuring contaminant-free air, businesses can extend the life of critical machinery and safeguard the integrity of their output. Whether it’s cement production where abrasive dust is a constant threat, or pharmaceutical manufacturing where sterility is non-negotiable, the right system ensures compliance with industry and regulatory requirements.

Finally, modern air filters contribute directly to sustainability and cost efficiency. By optimizing airflow, reducing energy consumption, and minimizing maintenance downtime, they help companies lower operational costs while aligning with global environmental goals. At Intensiv-Filter Himenviro, we don’t believe in generic solutions. Instead, we design custom-engineered filtration systems built to withstand the toughest industry conditions—protecting your people, your processes, and your profits.

Looking for the right industrial air filter system for your operation?

Liên hệ Intensiv-Filter Himenviro today for a personalized assessment and discover how a tailored solution can maximize efficiency, minimize costs, and ensure long-term compliance.

Những câu hỏi thường gặp

Baghouse filters with abrasion-resistant fabrics and high-temperature resistance are ideal for cement production, ensuring continuous uptime and reduced equipment wear.

They prevent contamination, maintain strict hygiene standards, and ensure compliance with food safety regulations, reducing risks of costly recalls.

Key factors include contaminant type, airflow volume, operating environment, compliance standards, and particle size requirements.

Our engineered solutions reduce downtime, cut maintenance costs, extend equipment life, and minimize product losses—delivering measurable ROI.