In industrial environments, combustible dust is more than just a nuisance—it’s a ticking time bomb. Whether in agriculture, woodworking, metal fabrication, chemical processing, or pharmaceuticals, airborne dust particles can ignite with explosive force, endangering lives and damaging infrastructure.

Until recently, navigating combustible dust safety meant juggling multiple NFPA standards, each targeting specific industries or materials. But in December 2024, the National Fire Protection Association released a revolutionary update: NFPA 660.

Designed to simplify and unify combustible dust regulations, NFPA 660 brings together six previously separate standards into a single comprehensive document. With more clarity, consistency, and actionable guidance, it’s now the cornerstone of dust hazard compliance.

This blog breaks down the core principles of NFPA 660, explains what’s new, and offers a roadmap to help your facility stay safe, compliant, and future-ready.

What is NFPA 660?

NFPA 660, officially titled Standard for Combustible Dusts and Particulate Solids, consolidates key NFPA documents into a single, comprehensive guideline. This strategic move by NFPA was meant to eliminate redundancies, reduce confusion, and streamline regulatory compliance across multiple industries.

Previously, dust safety was governed by a patchwork of standards:

NFPA 652: Fundamentals of Combustible Dust

NFPA 654: Manufacturing and Processing of Combustible Particulate Solids

NFPA 61: Agricultural and Food Processing

NFPA 484: Combustible Metals

NFPA 655: Sulfur Handling

NFPA 664: Woodworking and Wood Processing

All of these standards have now been integrated into NFPA 660, forming a more logical, accessible, and enforceable safety framework.

NFPA 660 is structured to address both universal dust hazards and industry-specific needs. It is designed to evolve over time, with regular updates expected every three years, starting with the next revision scheduled for 2027.

Why NFPA 660 Matters to Industrial Facilities

The release of NFPA 660 signals a major shift in how combustible dust safety is enforced and understood.

Combustible dust explosions can be catastrophic. Beyond the risk to life, these events lead to significant financial loss, legal liability, and business disruption. Regulatory bodies like OSHA often refer to NFPA standards when enforcing workplace safety under the General Duty Clause. Insurance providers also reference these standards when assessing risk and determining coverage.

By adopting NFPA 660, organizations can:

Simplify compliance with a single reference point

Mitigate explosion risks through unified safety protocols

Avoid citations during OSHA inspections

Lower insurance premiums by demonstrating proactive risk management

Improve the overall workplace safety culture

NFPA 660 Structure: Chapters and Annexes

NFPA 660 is organized into two primary sections: Chapters (numbered) and Annexes (alphabetical). This dual structure allows the standard to address both broad safety principles and detailed, material-specific guidance.

Core Chapters (1–10)

These chapters provide foundational guidance applicable across all industries. Topics include:

Chapter 7: Dust Hazard Analysis (DHA)

Chapter 8: Management Systems

Chapter 9: Hazard Mitigation and Prevention

Chapter 10: Emergency Planning and Response

Industry-Specific Chapters (21–25)

These chapters replace the older industry-specific standards:

Chapter 21: Agricultural and Food Processing (replaces NFPA 61)

Chapter 22: Combustible Metals (replaces NFPA 484)

Chapter 23: Sulfur (replaces NFPA 655)

Chapter 24: Woodworking Facilities (replaces NFPA 664)

Chapter 25: All Other Combustible Dusts (based on NFPA 654)

Informative Annexes (A–Z)

The annexes offer non-mandatory but highly valuable guidance. For example:

Annex B: Sample DHA Template

Annex Q: Explosion Protection Techniques

Annex R: Spark Detection and Suppression Systems

Annex T: Deflagration Isolation Methods

Annex W: Conveying System Isolation

Key Updates Introduced by NFPA 660

NFPA 660 goes far beyond simply combining documents. It introduces critical updates that reflect modern best practices, evolving technologies, and real-world challenges.

Dust Hazard Analysis (DHA)

NFPA 660 centralizes the requirements for DHA. Facilities that generate or handle combustible dust must perform a DHA every five years. The new standard refines the methodology and offers clearer expectations regarding documentation and revalidation.

Unified Terminology

Conflicting definitions across previous standards caused confusion during inspections and audits. NFPA 660 standardizes terminology, improving communication and enforcement.

Enhanced Risk Management Systems

Chapter 10 emphasizes continuous improvement over one-time compliance. Facilities are required to document inspection schedules, training programs, and emergency response protocols. This ensures a proactive, repeatable approach to risk mitigation.

More Detailed Dust Testing Guidelines

NFPA 660 clearly defines when and how to perform dust explosibility testing, covering:

Kst (Deflagration Index)

Pmax (Maximum Explosion Pressure)

MEC (Minimum Explosive Concentration)

MIE (Minimum Ignition Energy)

MIT (Minimum Ignition Temperature)

Risk-Based Housekeeping

Rather than fixed schedules, NFPA 660 promotes risk-based housekeeping plans. Facilities must assess the criticality of each area and set cleaning thresholds based on real hazard potential.

Interim Measures

When full compliance cannot be immediately achieved, NFPA 660 requires facilities to implement temporary safeguards to reduce immediate risk while long-term upgrades are planned.

Implementation Strategies: How to Comply with NFPA 660

Transitioning to NFPA 660 may appear complex, especially for facilities accustomed to the older individual standards. But a structured, step-by-step approach can ease the process.

Step 1: Build Internal Awareness

Distribute the NFPA 660 document to safety managers, maintenance teams, engineers, and executive leaders. Consider holding internal workshops or training sessions to explain the standard’s relevance.

Step 2: Conduct a Gap Analysis

Compare your existing dust safety procedures with the new requirements in NFPA 660. Focus on:

Last performed DHA (is it older than 5 years?)

Current explosion protection in dust collectors and ductwork

Bonding and grounding of all equipment

Venting and suppression system readiness

Step 3: Prioritize Corrective Actions

Address the highest-risk areas first. Immediate actions might include adding explosion vents to filter housings, upgrading to conductive ducting, or implementing hot work permit systems.

Step 4: Upgrade Engineering Controls

Invest in:

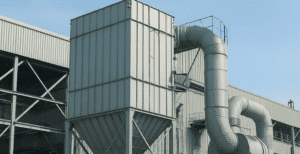

Advanced dust collection systems

Spark detection and suppression systems

Static grounding mechanisms

HEPA-grade secondary filters for air recirculation

Step 5: Update Administrative Programs

Review and revise:

Dust safety manuals

Inspection logs

Housekeeping schedules

Training documentation

Emergency response plans

Step 6: Engage Expert Support

Consult experienced firms for DHAs, system design, or safety audits. Equipment manufacturers like Intensiv Filter Himenviro stay up to date with evolving standards and can guide compliant system upgrades.

Industry Example: NFPA 660 in a Metal Processing Plant

A manufacturer handling aluminum powder must now follow Chapter 22 of NFPA 660. Upon conducting a gap analysis, they discovered:

The facility lacked explosion isolation in several duct runs

The existing DHA was outdated by six years

There were no formal housekeeping logs

By applying NFPA 660, they:

Installed isolation valves and explosion vents

Conducted a new DHA and implemented recommendations

Developed a detailed housekeeping and training plan

The result was not only compliance but enhanced safety culture, reduced insurance premiums, and fewer unscheduled shutdowns.

Looking Ahead: Preparing for Future Revisions

NFPA 660 is on a scheduled three-year revision cycle. The next update will arrive in 2027. Facilities that embed NFPA 660’s principles now will adapt more easily to future changes with minimal disruption.

Final Thoughts: A Safer Tomorrow Starts Today

NFPA 660 is more than a regulatory checklist—it’s a tool for building safer, smarter, and more resilient industrial environments. It clarifies what needs to be done, why it matters, and how to do it effectively.

By aligning your operations with NFPA 660, you not only meet compliance expectations but also protect your workforce, reduce operational risk, and establish your commitment to industrial excellence.

At Intensiv Filter Himenviro, we understand the stakes. Our team is ready to support your transition with engineered dust collection solutions, compliance consulting, and expert insights tailored to your industry.

Need Help Navigating NFPA 660?

Contact our team today to schedule a consultation or dust safety audit. We’re here to ensure your operations are compliant, efficient, and protected.