Văn phòng

TRỤ SỞ CHÍNH

Đức

-

Bộ lọc chuyên sâu Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Đức - +49 20534200990

VĂN PHÒNG KHU VỰC

Anh quốc

-

Bộ lọc chuyên sâu Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Vương quốc Anh - +44 1922 628893

VĂN PHÒNG KHU VỰC

Các Tiểu Vương Quốc Ả Rập Thống Nhất

-

Bộ lọc chuyên sâu Himenviro Technologies FZE – LLC

Trung tâm thương mại, Khu thương mại tự do Sharjah Publishing City, Sharjah, UAE - +971-556074697

VĂN PHÒNG KHU VỰC

Ấn Độ

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Khu vực 63, Noida - 201301, Uttar Pradesh, Ấn Độ - +91-120-4642-500

VĂN PHÒNG KHU VỰC

Ấn Độ

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Khu vực 63, Noida - 201301, Uttar Pradesh, Ấn Độ - +91-120-4642-500

VĂN PHÒNG KHU VỰC

Ấn Độ

-

Intensiv-Filter Himenviro Private Limited

D-247/11, Khu vực 63, Noida - 201301, Uttar Pradesh, Ấn Độ - +91-120-4642-500

Food Industry Air and Dust Filtration Solutions

The food and beverage industry is a complex and highly regulated sector that relies on precise processes and stringent hygiene standards. One critical aspect of maintaining these standards is effective dust control. Processes such as grain handling, mixing, blending, and packaging generate fine dust particles that can contaminate products, pose health risks to workers, and create potential explosion hazards.

To address these challenges, We offer advanced filtration solutions specifically designed for the food and beverage industry. Our systems are engineered to capture and remove dust particles, ensuring product purity, worker safety, and regulatory compliance.

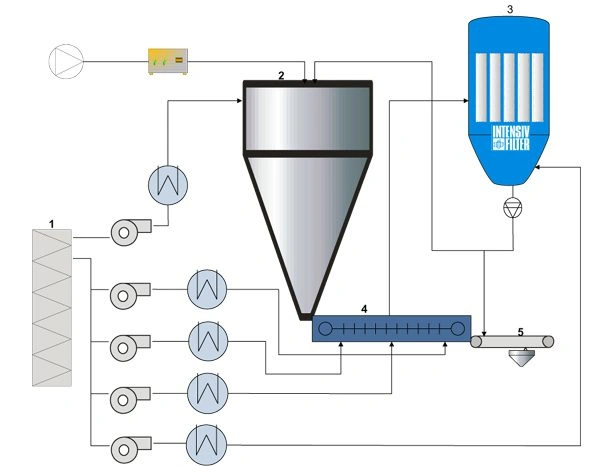

Dust Filtration Process in the Food Industry

- 1. Bộ lọc bên ngoài

- 2. Máy sấy phun

- 3. Bộ lọc CIP

- 4. Lớp lưu hóa ngoài

- 5. Làm đầy

Required Specification For the CIP Filter

Our Products Application for the Food Industry

Capture dust generated during the transfer of bulk materials, such as grains, powders, and flakes.

Kết nối với chúng tôi để được tư vấn chuyên gia

Khám phá các dịch vụ khác của chúng tôi!

Những câu hỏi thường gặp

In food processing, common filtration systems include membrane filters (such as microfiltration, ultrafiltration, nanofiltration, and reverse osmosis), depth filters, activated carbon filters, and ultraviolet (UV) light systems. These technologies are employed to remove physical, chemical, and biological contaminants, ensuring product purity and safety.

Filtration systems ensure compliance with food safety standards by effectively removing contaminants, including microorganisms, particulates, and chemical residues, from raw materials and products. This purification process helps meet regulatory requirements and maintains high-quality standards in the final food products.

Filtration systems maintain product quality and consistency by removing unwanted particulates, microorganisms, and other contaminants from ingredients and final products. This ensures that each batch meets the desired purity and quality standards, leading to uniformity in taste, appearance, and safety across all products.